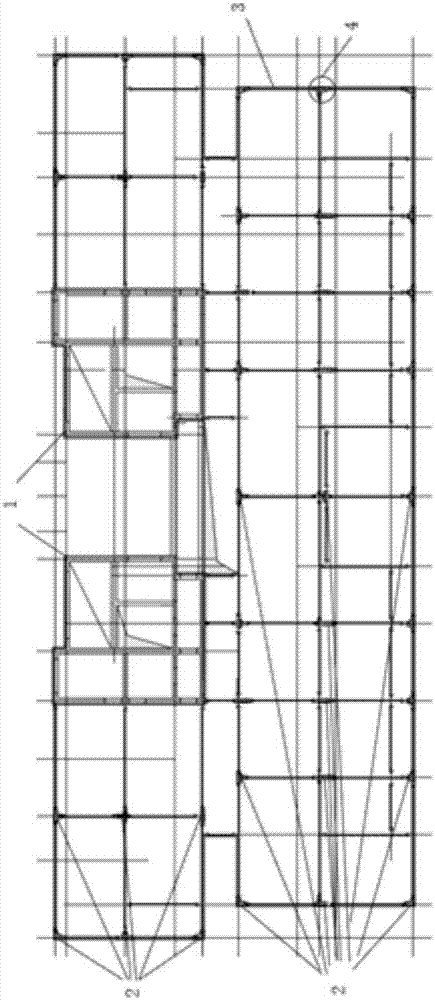

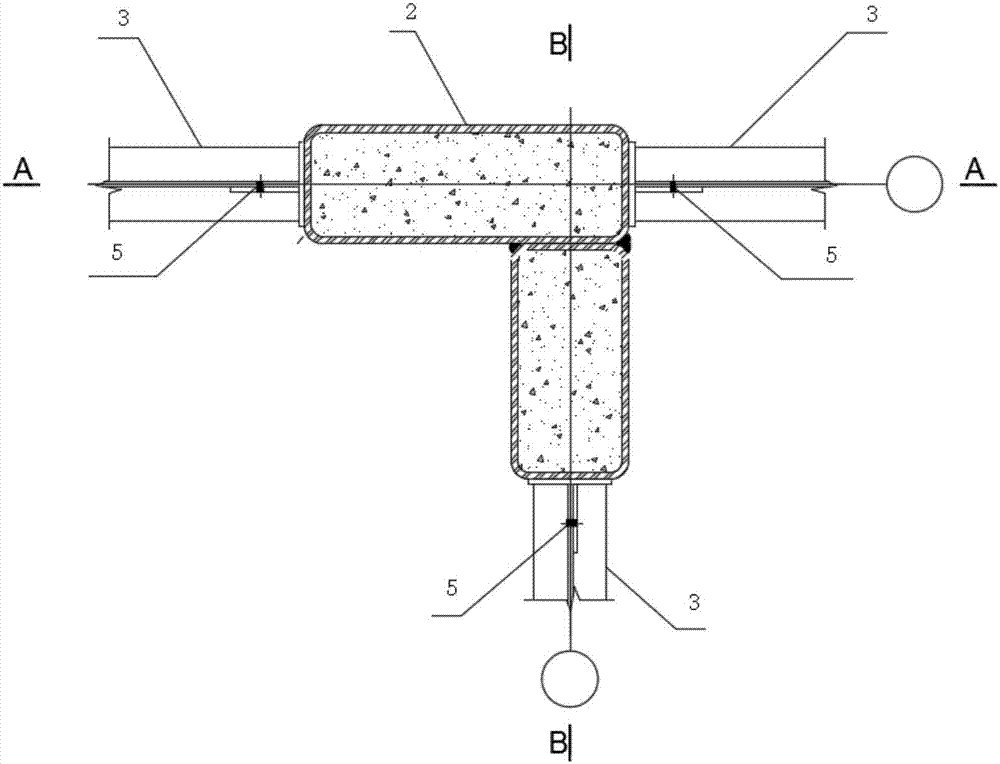

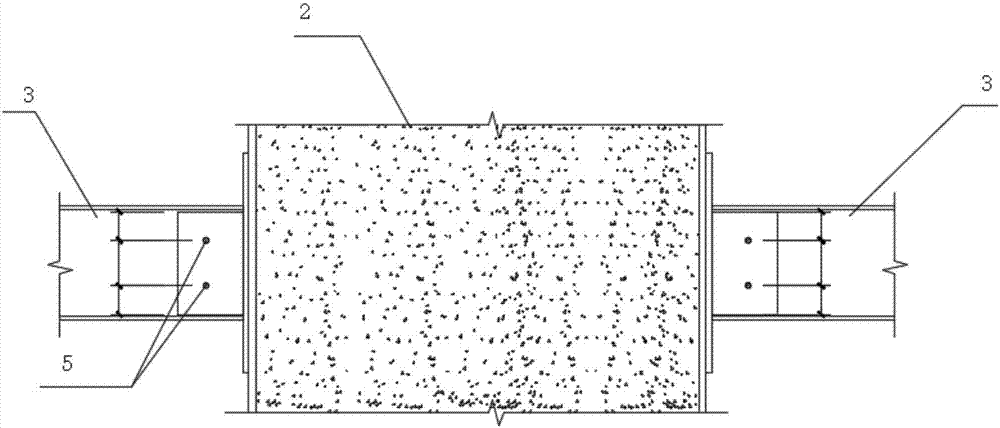

Steel reinforced concrete core tube and rectangular concrete filled steel tube special-shaped column structural system

A rectangular steel tube and concrete technology, applied in special structures, building components, etc., can solve the problems of low assembly, affecting building functions, and small internal space of steel columns, so as to reduce steel consumption indicators, improve economic applicability, The effect of preventing premature buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to solve the problems of small internal space of special-shaped steel columns in the technical field of construction engineering, complicated horizontal cross-section structure, cumbersome manufacturing of factory components, too many welding seams in construction and installation, heavy workload of on-site welding, high steel consumption indicators, and high building construction costs, etc. Problem, the inventor considers that the design is applicable to the column building profiles of middle and high-rise buildings.

[0050] The inventors of the present invention found that filling concrete into circular or rectangular steel pipes, the formed steel pipe concrete columns have many advantages such as simple construction, convenient industrial production, reusable steel materials, energy saving and environmental protection, and are suitable for prefabricated steel structure buildings construction.

[0051] However, the section size of this single traditional re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com