Exhaust gas purifying system for vessel engine

An exhaust gas purification system and engine technology, which is applied to motor-driven engines, engine components, combustion engines, etc., to achieve the effect of saving man-hours, reducing burdens, and labor-saving burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

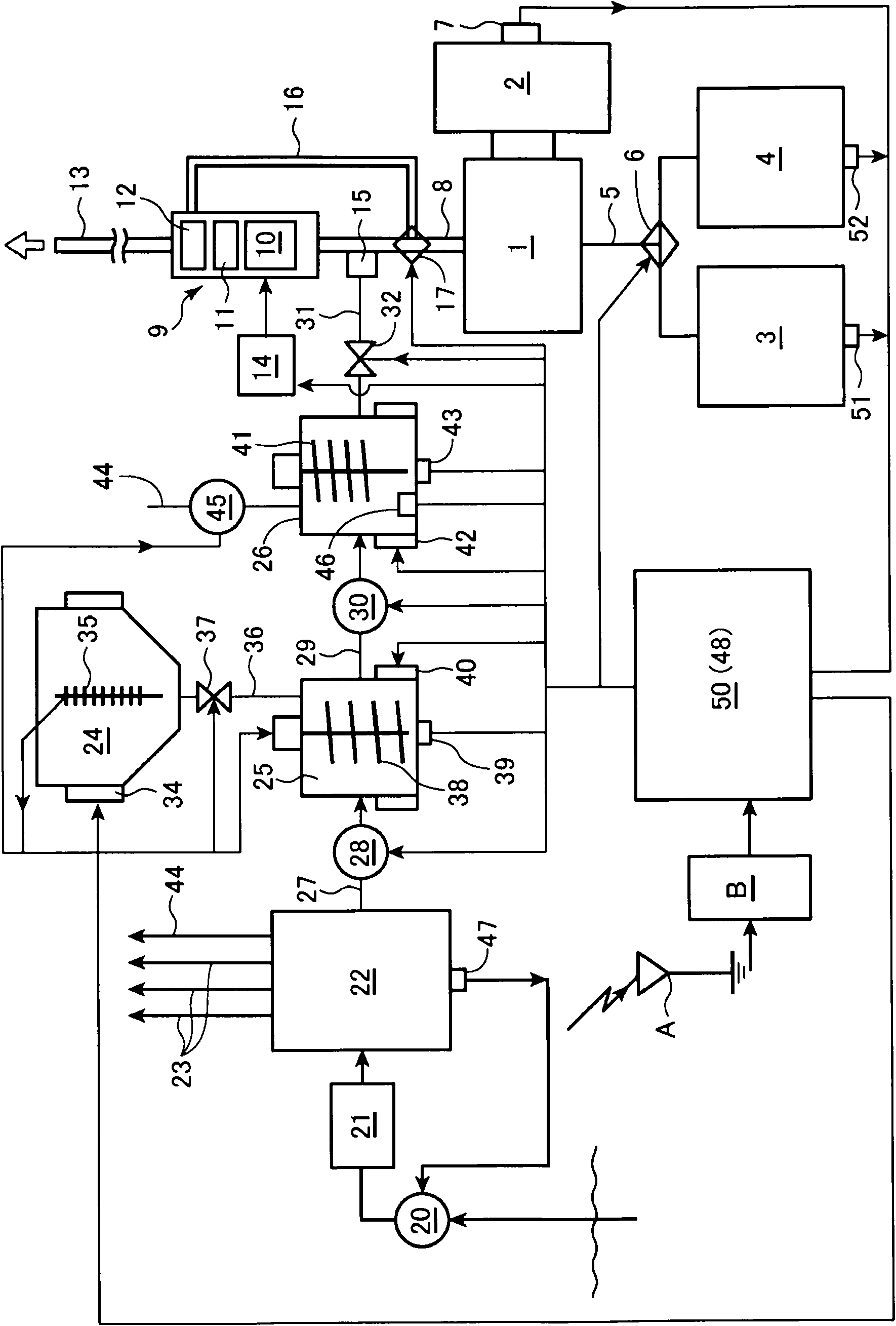

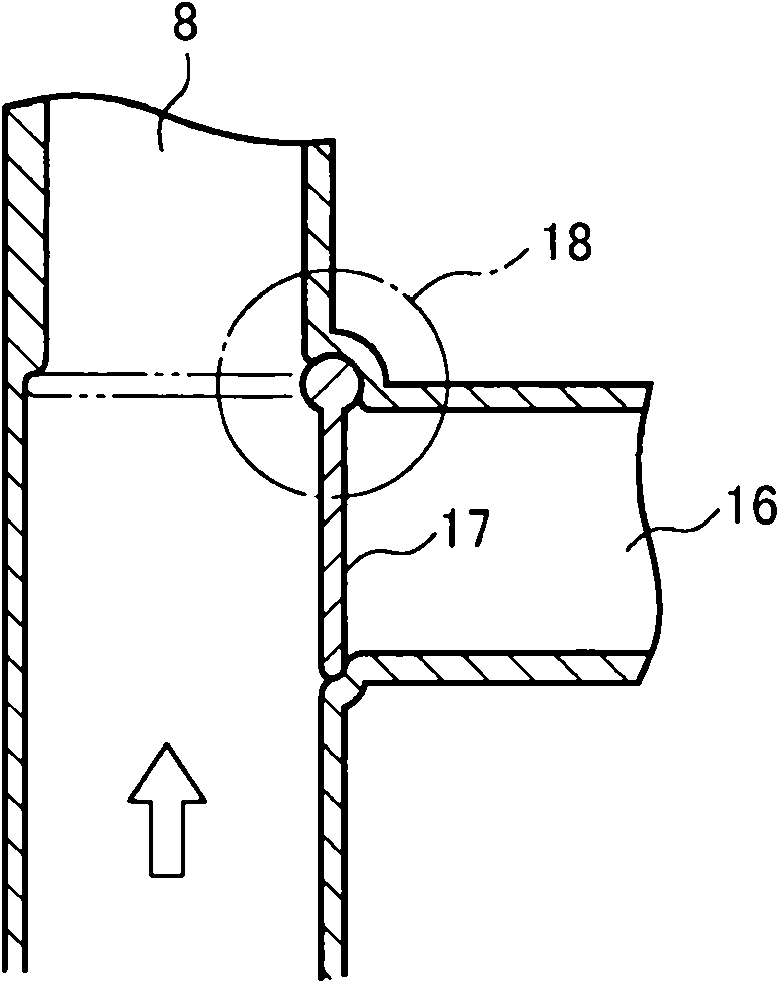

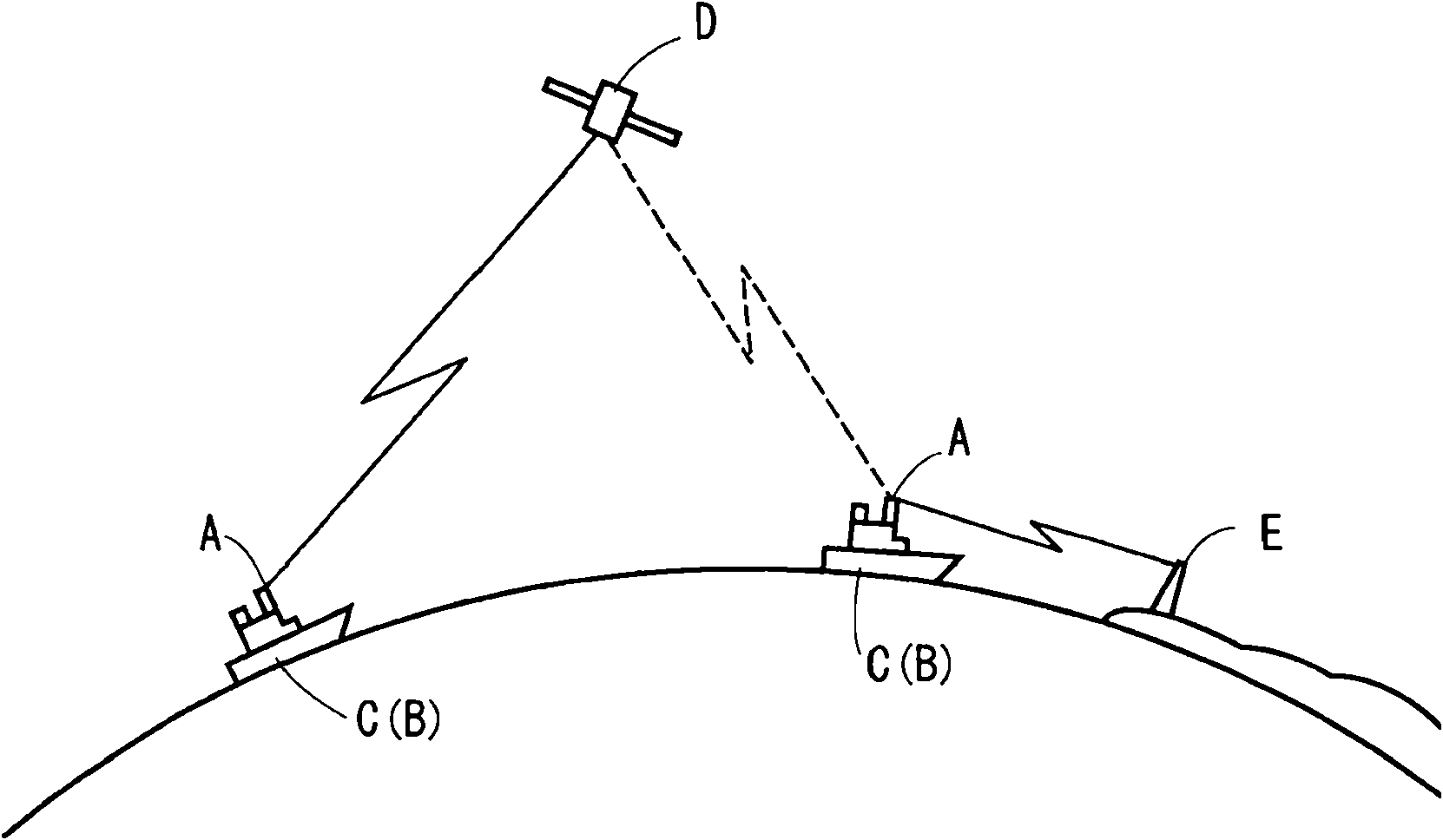

[0046] Next, embodiments of the invention of the present application will be described with reference to the drawings. figure 1 It is a conceptual block diagram showing equipment and devices related to the invention of the present application, figure 2 is a diagram showing the specific structure of the device, image 3 It is a concept image of a ship under sail. First, the arrangement and the like of the facilities and devices will be described.

[0047] (1).Basic structure around the engine

[0048] Such as figure 1 As shown, the ship has a diesel engine 1 , and a generator 2 is connected to the engine 1 . The engine 1 is supplied with fuel from any one of a normal fuel tank 3 and a low-sulfur fuel tank 4 . exist figure 1 In the figure, in order to simplify the description, the state in which the switching valve (three-way valve) 6 is interposed on the fuel line 5 connecting the two fuel tanks 3, 4 and the engine 1 is described, but in practice, it can be considered th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com