Substrate fixture and rotary disc for coating film and film coating machine

A substrate holder and turntable technology, which is applied in sputtering plating, ion implantation plating, vacuum evaporation plating and other directions, can solve the problems of wasting man-hours, wasting costs and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

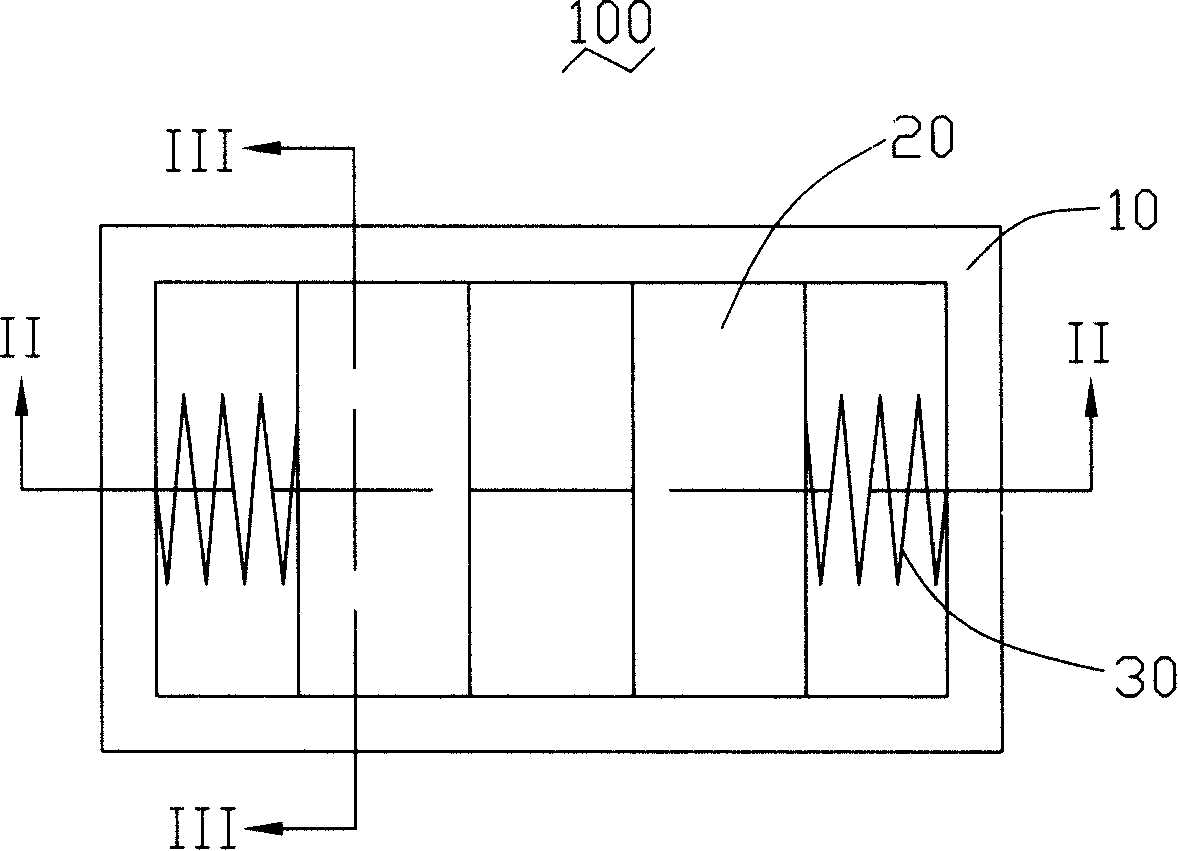

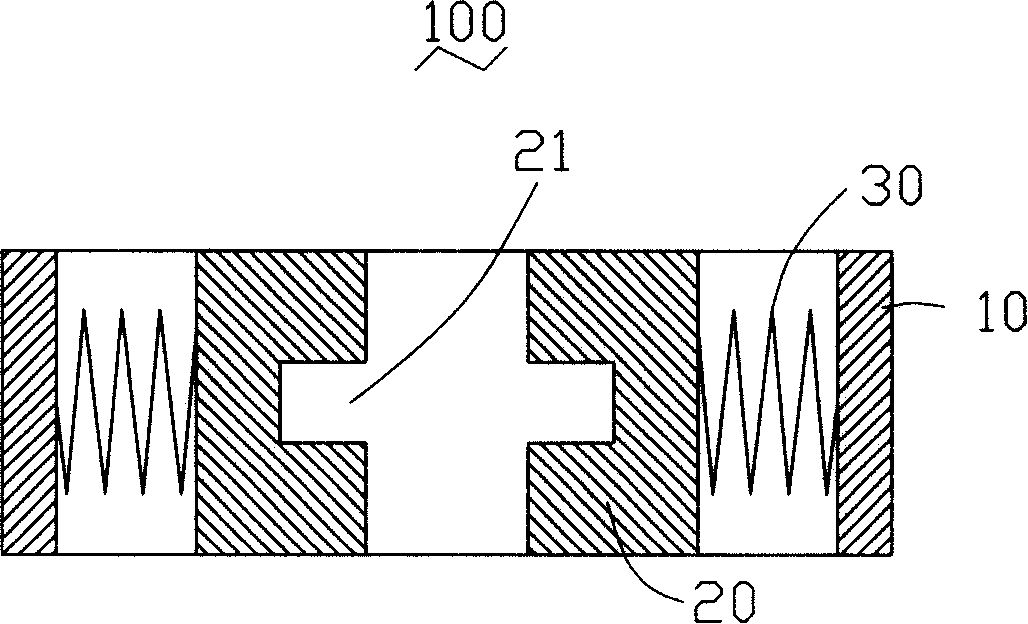

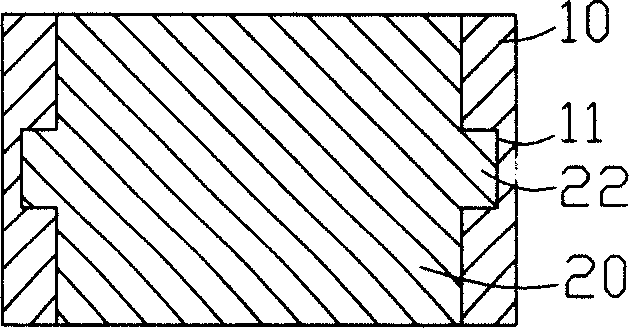

[0017] Please also refer to figure 1 and figure 2 , the substrate holder 100 of the present invention includes a frame body 10, two clamping parts 20 that are arranged oppositely and are slidably installed in the frame body 10, and a plurality of elastic parts connecting the frame body 10 and the clamping parts 20. 30 pieces. The opposite surfaces of the two clamping parts 20 are provided with a clamping part 21 for clamping the substrate, and the elastic force of the plurality of elastic parts 30 acts on the two clamping parts 20 so that the two clamping parts 20 hold the substrates facing each other.

[0018] The frame body 10 is a square frame body, and its material can be wood, plastic or steel. The frame body 10 in this embodiment is made of steel. The clamping part 20 is a block matching the shape of the frame body 10, and its material is wood, plastic or steel. The clamping part 20 in this embodiment is made of steel. The clamping portion 21 is a groove defined in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com