Low profile clamp for use with apparatus for thermal control in the analysis of electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

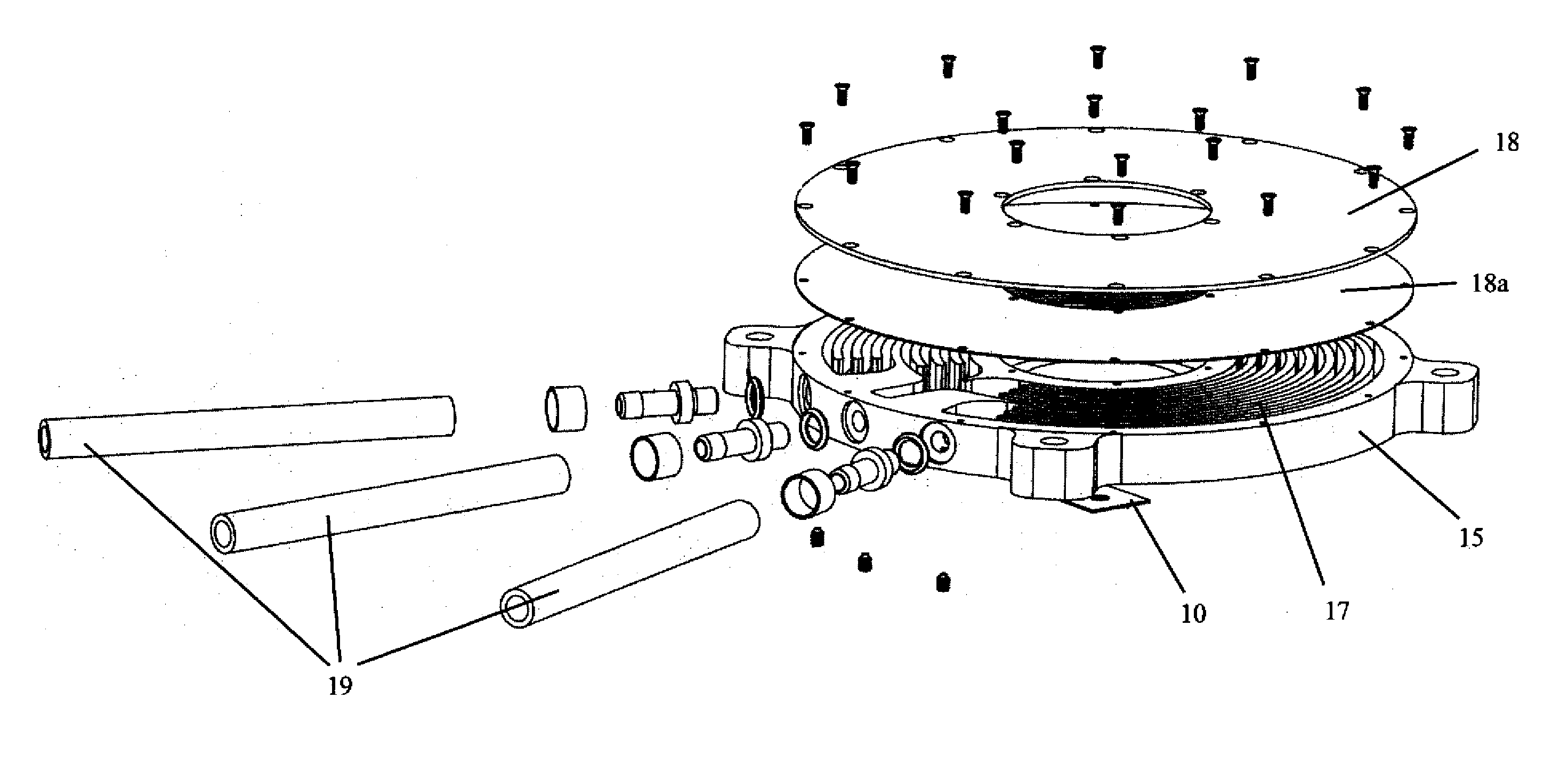

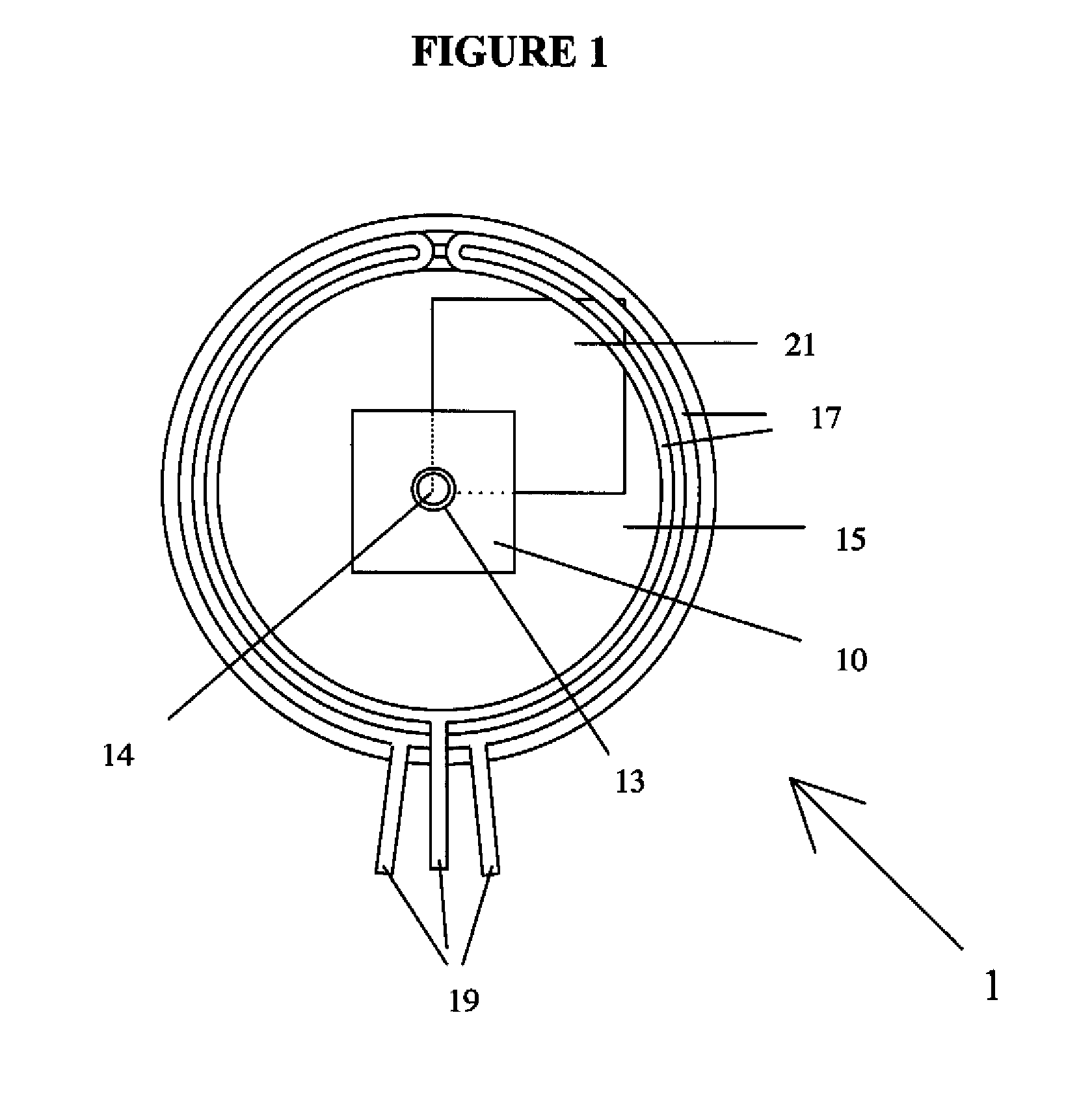

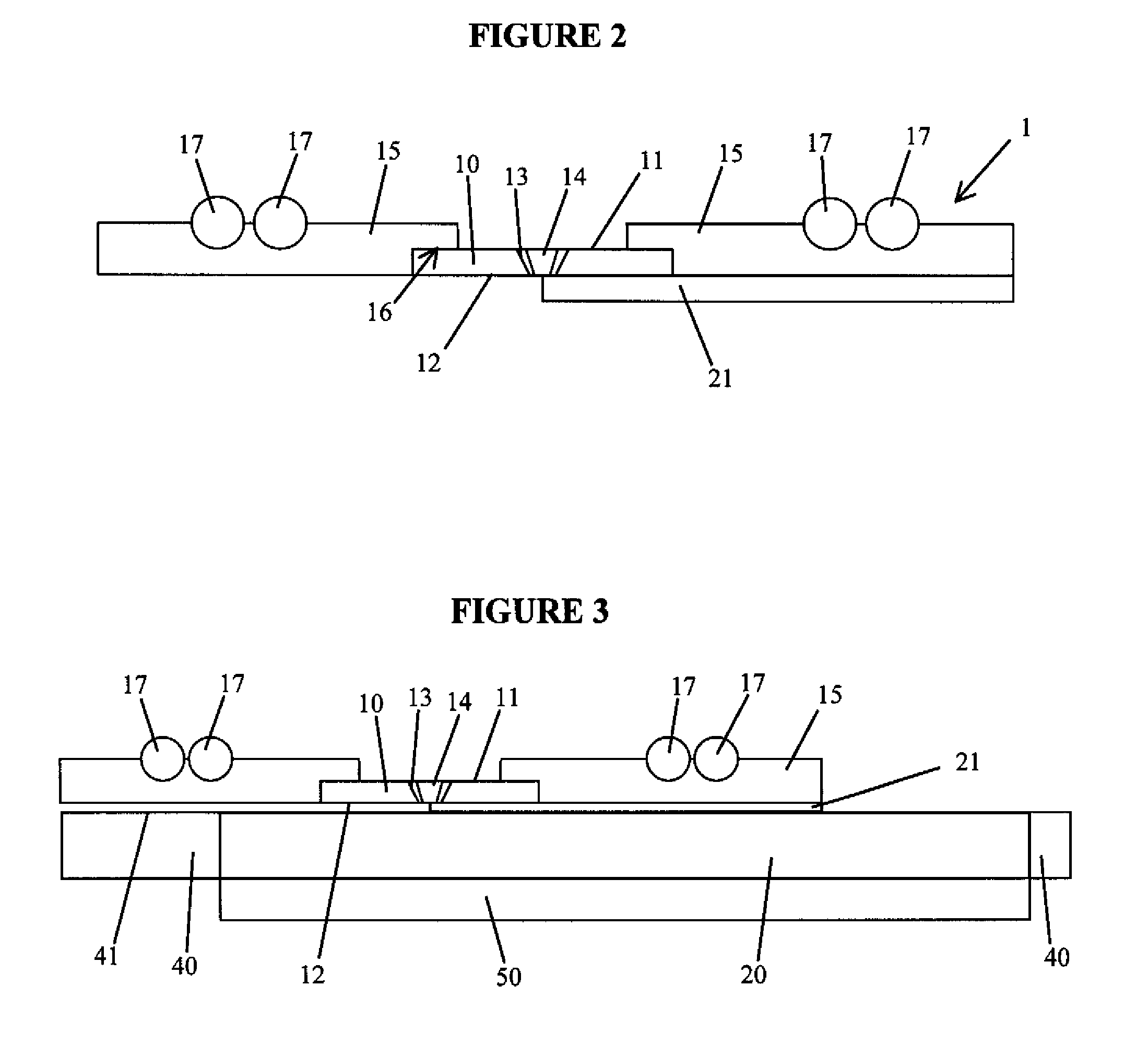

[0042]FIGS. 1 to 3 show a heat spreader 1 according to the present invention. The heat spreader 1 includes a sheet 10 of transparent diamond having a first surface 11 and a second surface 12 and an aperture 13 formed between the first surface 11 and the second surface 12. The diamond sheet 10 preferably has a thickness of 500 μm.

[0043]The aperture 13 is shaped and sized to accommodate a SIL 14. The SIL 14 typically has a diameter of 1-4 mm. Consequently, the aperture 13 typically has a diameter of approximately 1-4 mm.

[0044]In order to improve optical access to the SIL, the aperture 13 in the diamond sheet 10 is conical such that the area of the cross-section of the aperture 13 at the first surface 11 is larger than the area of the cross-section of the aperture 13 at the second surface 12. The walls of the aperture 13 are smooth in order to improve imaging through the diamond 10. The provision of the conical aperture 13 allows the same heat spreader to be used with SILs of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com