Optical element having integral surface diffuser

An optical component and overall technology, applied in the field of optical components, can solve the problems of reducing the performance and practicability of interlayer optical components, scattering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

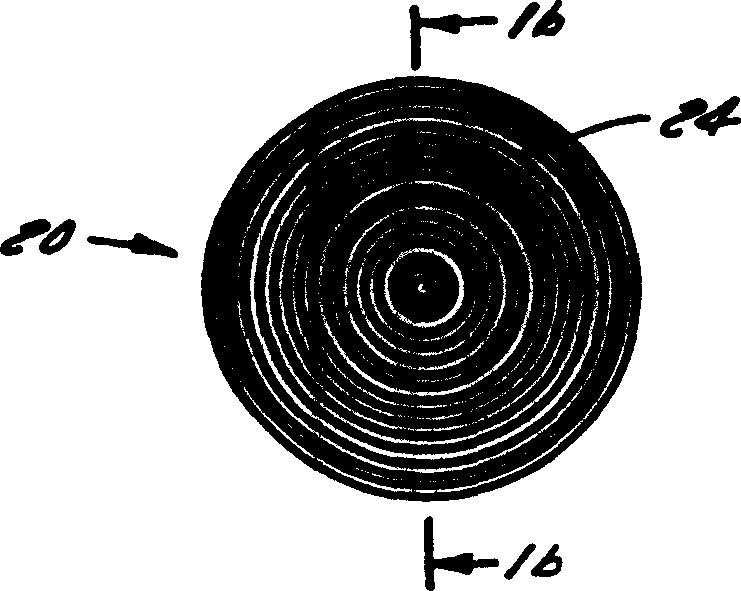

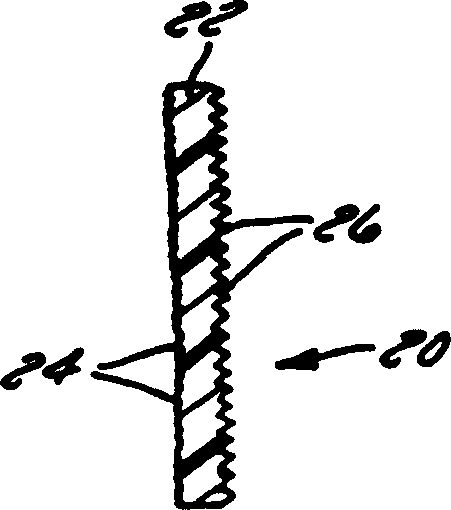

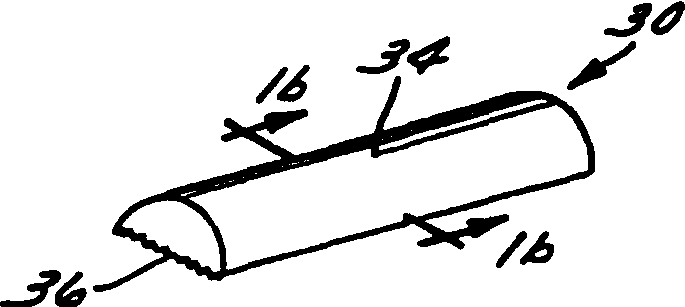

[0034] Based on the above-listed patents and pending applications assigned to the assignee of the present inventor, the assignee has developed a number of methods for optically or mechanically creating microetched surface structures randomly within a substrate and microstructure, and produce a light output with smooth consistent and continuous intensity. These microstructures can also be used to control the direction of light output from the light source so that the output light forms a desired distribution pattern or envelope. Published patents consist in the use of various means to form these surface structures in photoresist materials and to replicate these structures on sub-stencils. Using these sub-stencils it is also possible to replicate microstructures on sheets, which may be sandwiched, or another sheet applied to the object, in order to provide uniform, shaped and directional light . The pending application discloses other developed techniques to form these microst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com