Gradient refractive index anti-reflection film and preparation method and application thereof

A technology of graded refractive index and refractive index, applied in the field of graded refractive index anti-reflection film and its preparation, can solve the problems of Fresnel reflection loss and other problems, achieve the effect of eliminating reflection loss, realizing deposition, and a wide range of deposition conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

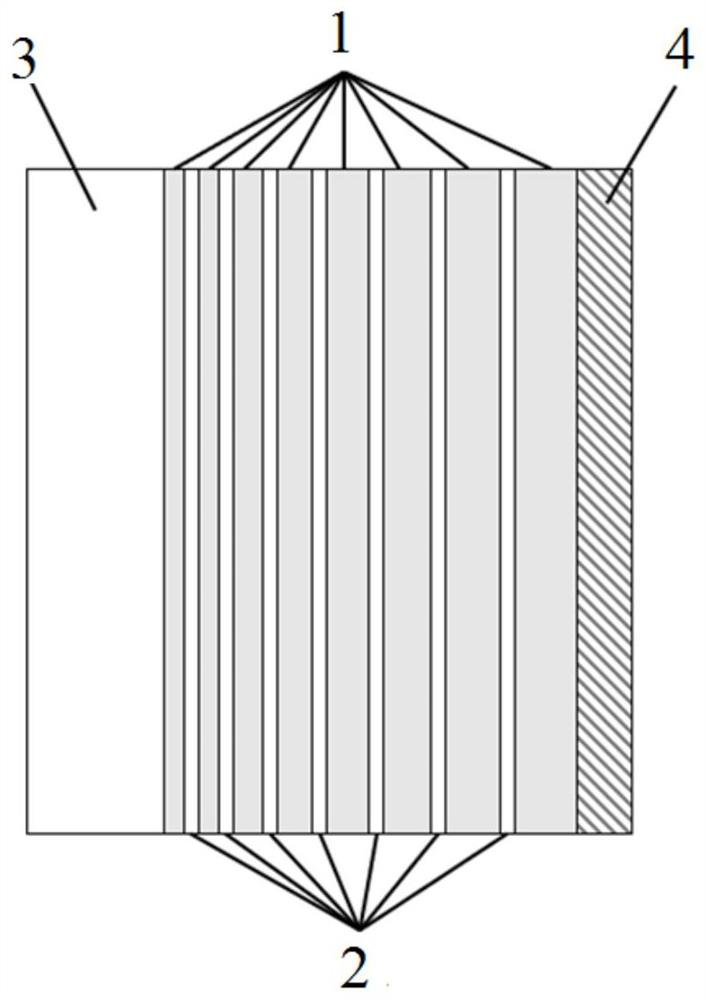

[0075] Such as figure 1 As shown, an embodiment of the present invention proposes a method for preparing a graded index antireflection film, which includes the following steps:

[0076] Step 1: Obtain the first functional layer 3 and the second functional layer 4;

[0077] In this step 1, the refractive index difference between the first functional layer and the second functional layer is relatively large.

[0078] The large difference in refractive index between the first functional layer and the second functional layer will cause a large loss of Fresnel reflection. In this embodiment, a gradient index anti-reflection film is prepared in the middle to reduce Fresnel reflection. loss. In some preferred embodiments, the first functional layer and the second functional layer are an input window and a photocathode, respectively. In this embodiment, a graded index anti-reflection film is prepared between the input window and the photocathode to eliminate the reflection loss bet...

Embodiment 1

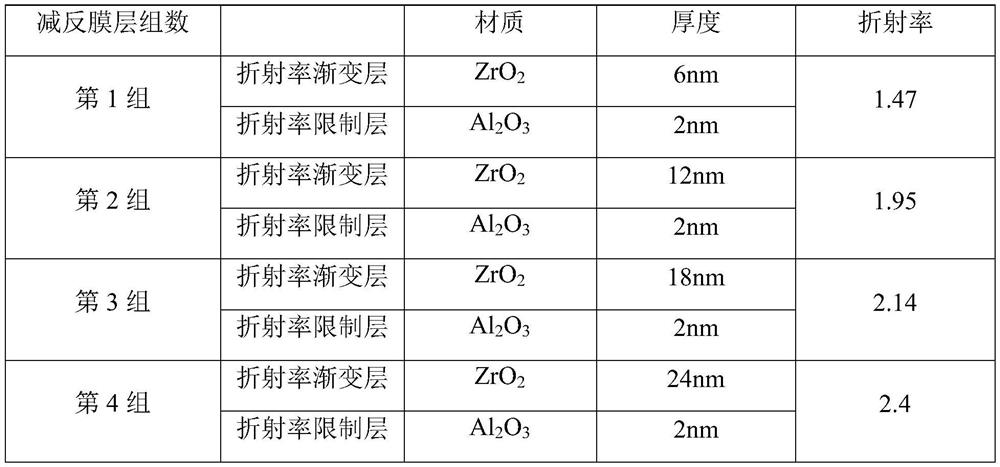

[0120] This embodiment 1 provides a method for preparing a graded index antireflection film, and its specific implementation steps are as follows:

[0121] Step 1. Select ZrO 2 As the graded index layer, select Al 2 o 3 As a refractive index limiting layer, it is prepared by chemical vapor deposition, ZrO 2 The deposition rate is 6nm / min, Al 2 o 3 The deposition rate is 1nm / min;

[0122] Step 2. Clean the input window with deionized water, ethanol, and isopropanol and place it in the chemical vapor deposition chamber. Deposit the first group of anti-reflection coatings on the input window according to the operation steps of chemical vapor deposition. The deposition time of the group anti-reflection coating layer is 1 minute, and the deposition time of the refractive index limiting layer is 2 minutes;

[0123] Step 3, depositing the second group of anti-reflection coatings, the deposition time of the refractive index gradient layer of the second group of anti-reflection coa...

Embodiment 2

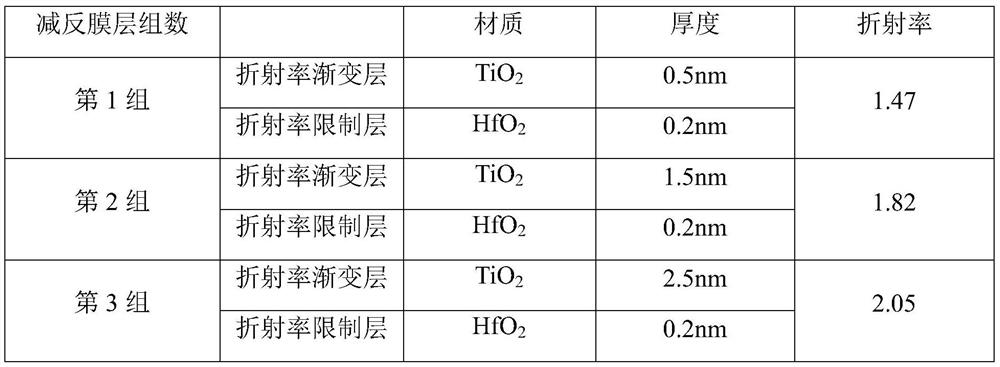

[0131] This embodiment 2 provides a method for preparing a graded-index antireflection film, and its specific implementation steps are as follows:

[0132] Step 1. Select TiO 2 As the graded index layer, choose HfO 2 As a refractive index limiting layer, prepared by atomic layer deposition (ALD), TiO 2 The deposition rate is 0.05nm / min, HfO 2 The deposition rate is 0.02nm / min;

[0133] Step 2. Clean the input window with deionized water, ethanol, and isopropanol and place it in the ALD chamber. Deposit the first group of anti-reflection coatings on the input window according to the ALD operation steps. The first group of anti-reflection coatings The deposition time of the graded refractive index layer of the layer is 10 minutes, and the deposition time of the refractive index limiting layer is 10 minutes;

[0134] Step 3, depositing the second group of anti-reflection coatings, the deposition time of the refractive index gradient layer of the second group of anti-reflectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com