Converter waste heat generating system

A waste heat power generation and converter technology, used in the manufacture of converters, machines/engines, mechanical equipment, etc., can solve the problems of dangerous steam turbines, large steam consumption, low power generation efficiency, etc., to improve power generation efficiency, ensure normal operation, reduce The effect of the amount of condensed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

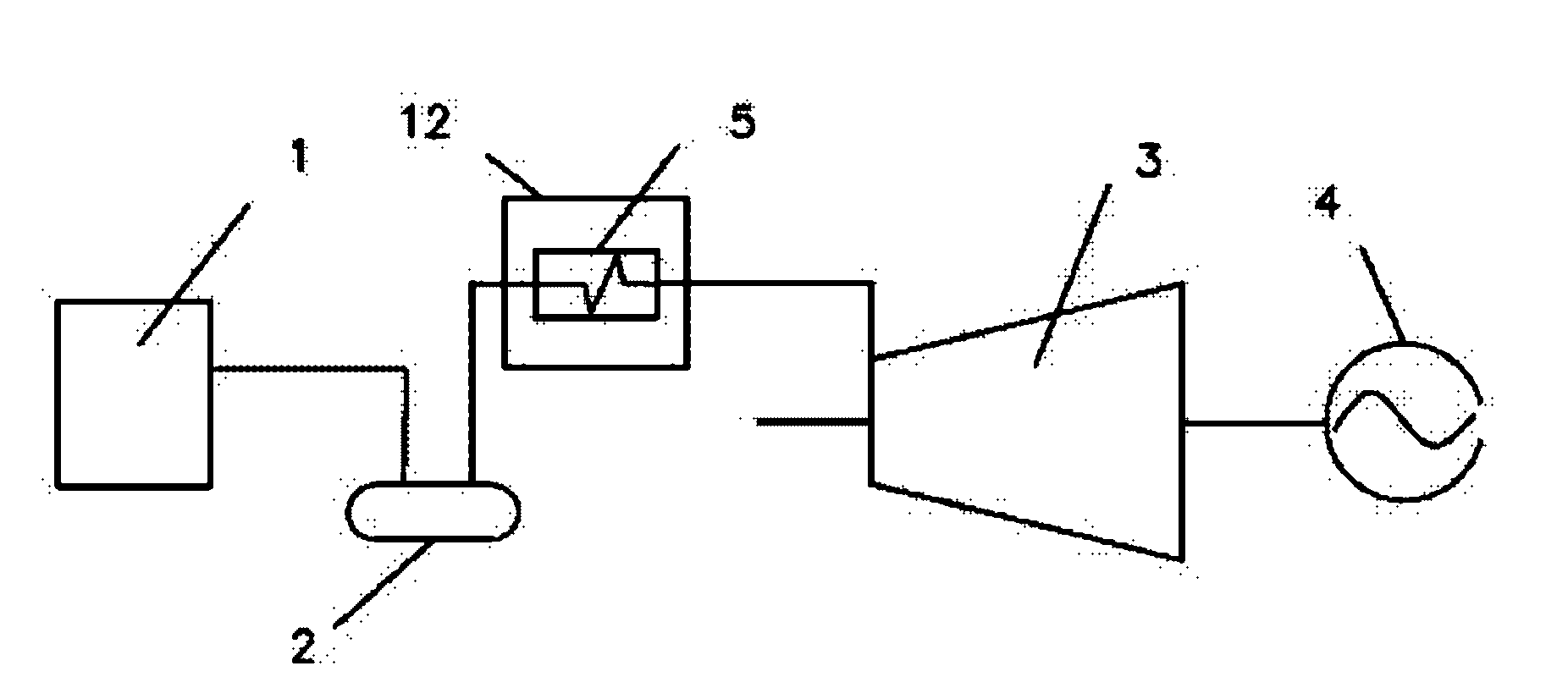

[0015] Such as figure 1 As shown, the converter waste heat power generation system described in this embodiment includes a waste heat boiler 1, a heat accumulator 2, a steam turbine unit 3, and a generator set 4. The steam outlet of the waste heat boiler 1 is connected to the steam inlet of the heat accumulator 2. The feature is that it also includes a heating furnace 12 containing a superheater 5 , and the steam outlet of the heat accumulator 2 is connected with the steam inlet of the steam turbine unit 3 through the superheater 5 . The saturated steam generated by the waste heat boiler 1 is stabilized by the heat accumulator 2, and heated into superheated steam by the superheater 5 to improve the quality of the steam. The water contained in the saturated steam is heated into water vapor, so that it becomes dry steam, thereby effectively reducing the amount of condensed water produced when it works inside the steam turbine. In addition, the superheater 5 can increase the spec...

Embodiment 2

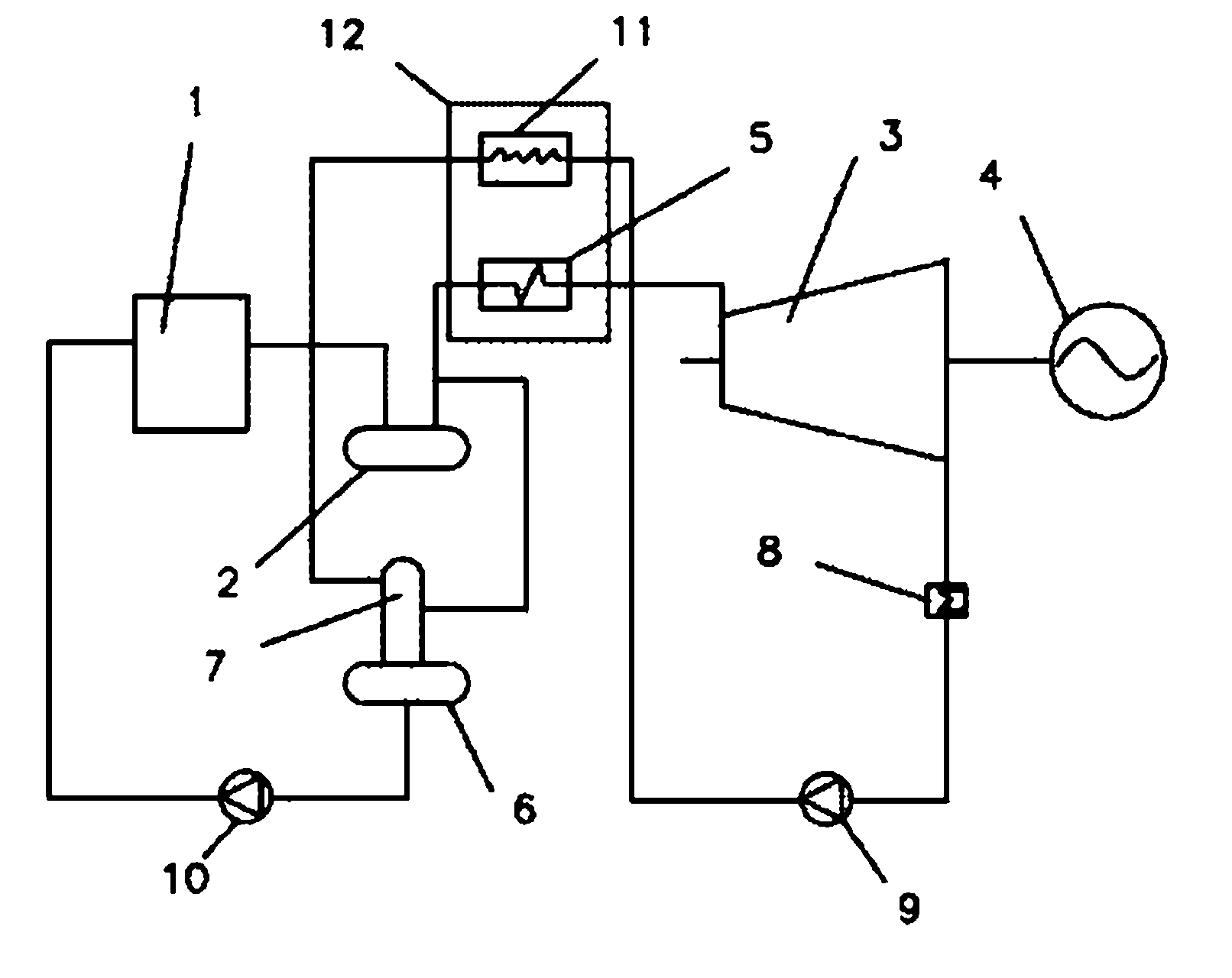

[0018] Such as figure 2 As shown, the converter waste heat power generation system described in this embodiment is different from Embodiment 1 in that the water inlet of the waste heat boiler 1 is connected to the deaerator water tank 6, and the deaerator water tank 6 is integrally connected with a deaerator head 7 The steam outlet of the steam turbine unit 3 is connected to a condenser 8, and the outlet of the condenser 8 is connected to the water inlet of the deaeration head 7 through the condensed water heater 11 in the heating furnace 12. Water resources can be effectively saved by condensing and deoxygenating the steam after work is done, and returning it to the waste heat boiler 1 again.

Embodiment 3

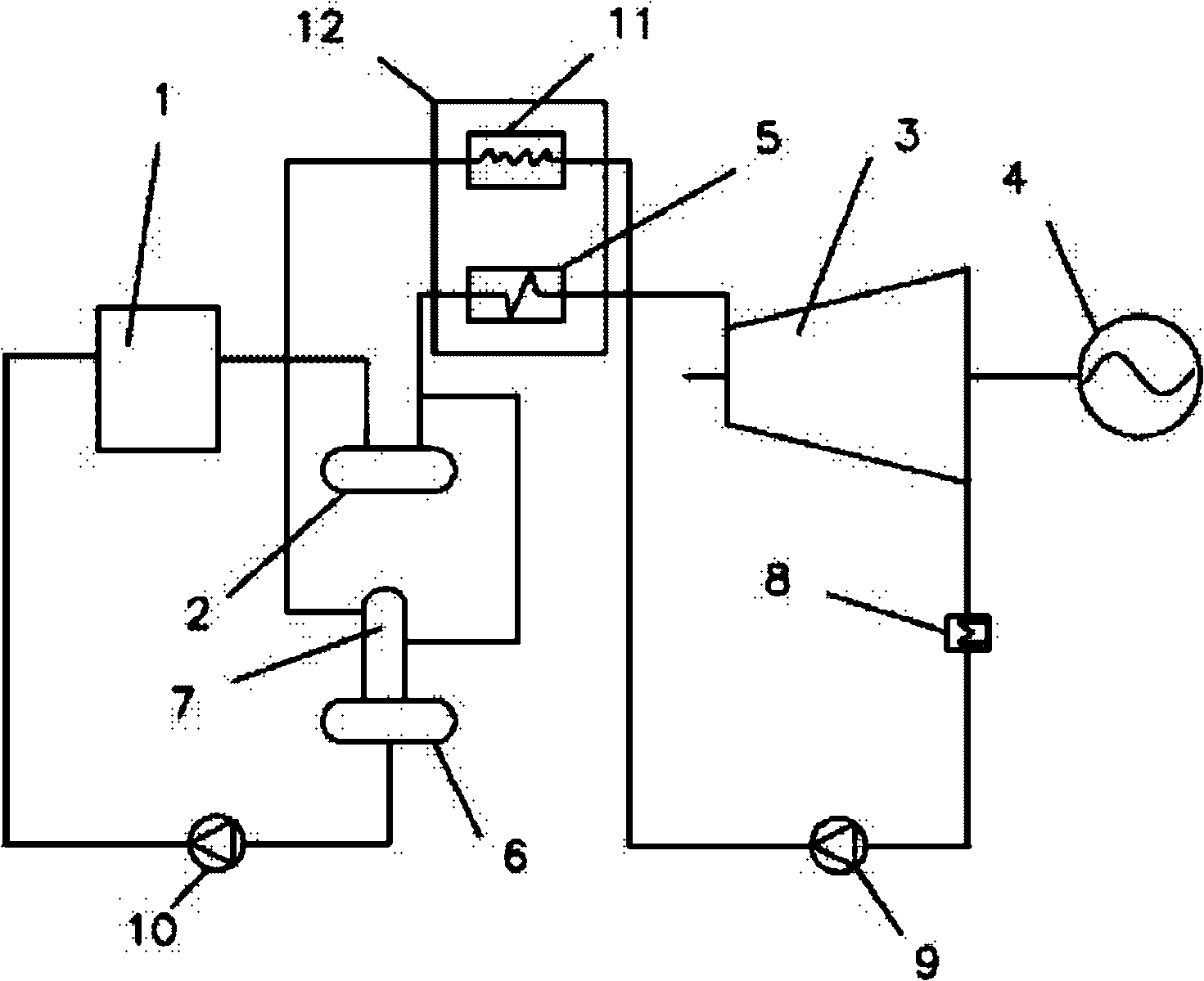

[0020] In the converter waste heat power generation system described in this embodiment, the waste heat boiler 1 is a steel plant converter waste heat boiler 1 , and the others are the same as in the second embodiment.

[0021] When in use, the saturated steam supplied by the converter waste heat boiler 1 is absorbed in the heat accumulator 2, and converted into a stable and continuous steam source, heated by a heater to become superheated steam, and worked by a steam turbine until the generator generates electric energy, and the steam turbine unit 3. The steam at the end is condensed into water through the condenser 8, transported to the deaeration head 7 by the deaeration water tank 6 through the condensate pump 9 for deaeration, and returned to the converter waste heat boiler 1 through the feed water pump 10, and heated into superheated steam by the superheater 5. Stable and continuous power generation, significantly improving power generation efficiency.

[0022] The iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com