High-performance plate heat exchanger capable of performing switching and back flushing

A plate heat exchanger and backwashing technology, applied in heat exchanger types, indirect heat exchangers, flushing, etc., can solve the problems of poor sealing, easy scaling in cold water chambers, and easy aging of sealing gaskets. Achieve the effect of reducing scaling, saving spare parts replacement and labor costs, and reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

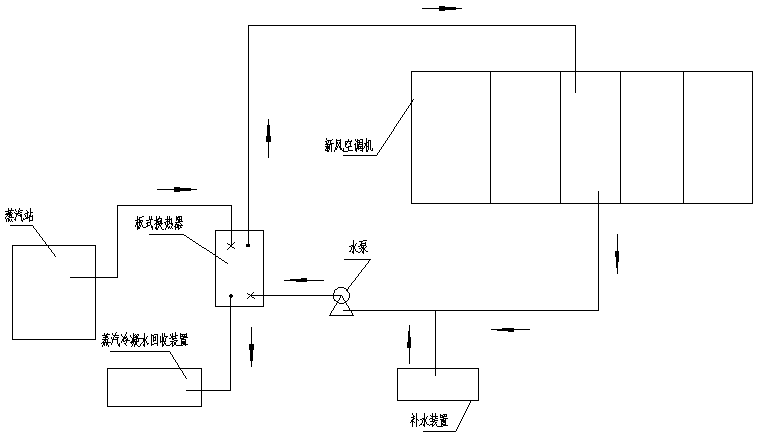

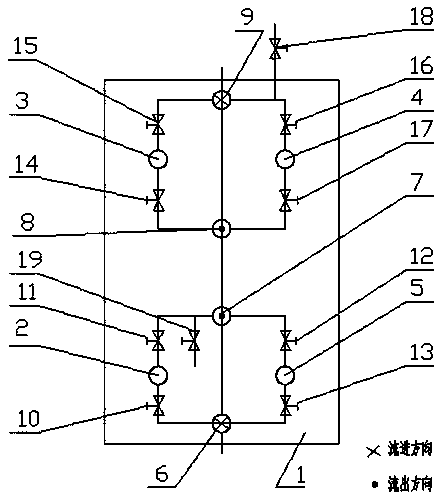

[0016] The technical solution of the present invention will be further described below according to the accompanying drawings.

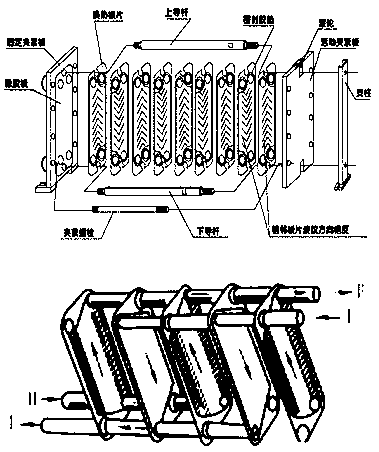

[0017] Such as figure 2 The main body of the switchable and backwashing high-performance plate heat exchanger shown is the same structure as the general-purpose plate heat exchanger, mainly including several rectangular thin metal heat exchange plates, movable clamping plates, fixed clamping plates, sealing Rubber pads, upper guide rods, lower guide rods, and clamping bolts; several heat exchange plates are arranged in parallel with each other, and are fixed by connecting the upper guide rods and the lower guide rods; one end of the upper guide rods and the lower guide rods is connected with a fixing clip The other end of the clamping plate is connected to the movable clamping plate, and the fixed clamping plate and the movable clamping plate are connected and fixed by several tightening bolts.

[0018] The sealing rubber pad of the main body of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com