Compressed gas cooling apparatus

a cooling apparatus and compressed gas technology, applied in lighting and heating apparatus, ventilation systems, heating types, etc., can solve the problems of increased power consumption and pressure loss, and achieve the effect of reducing pressure drop and reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

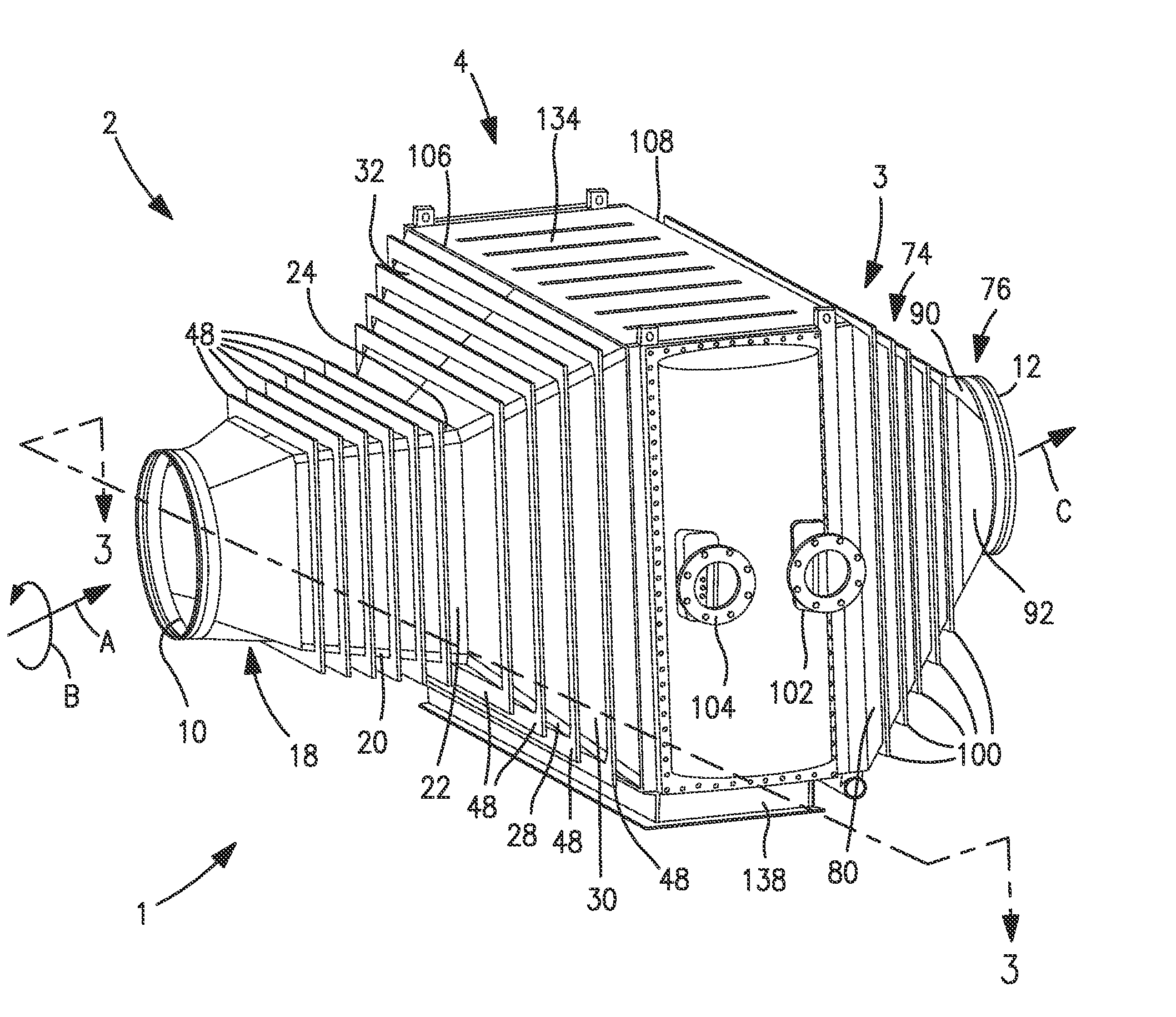

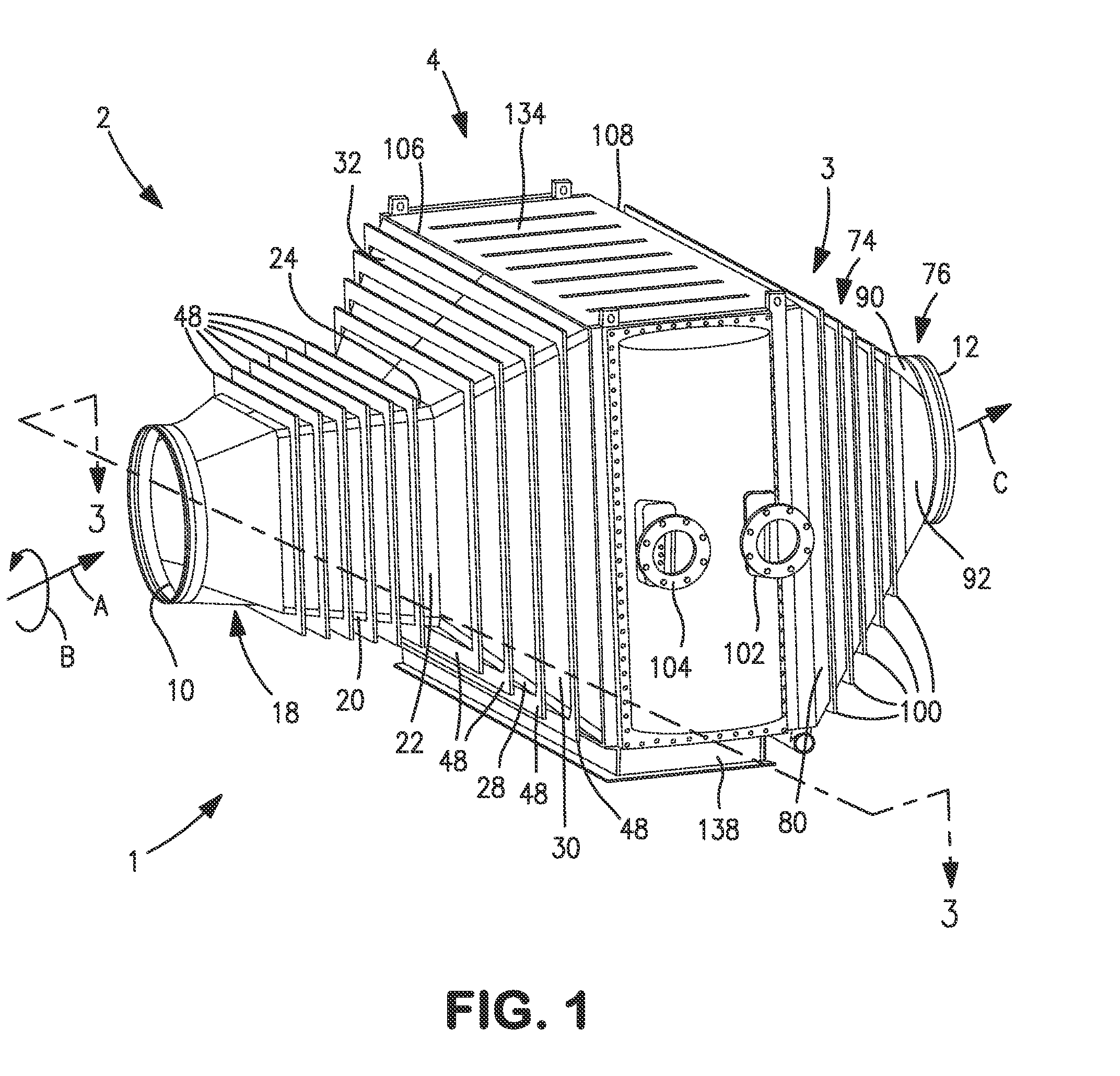

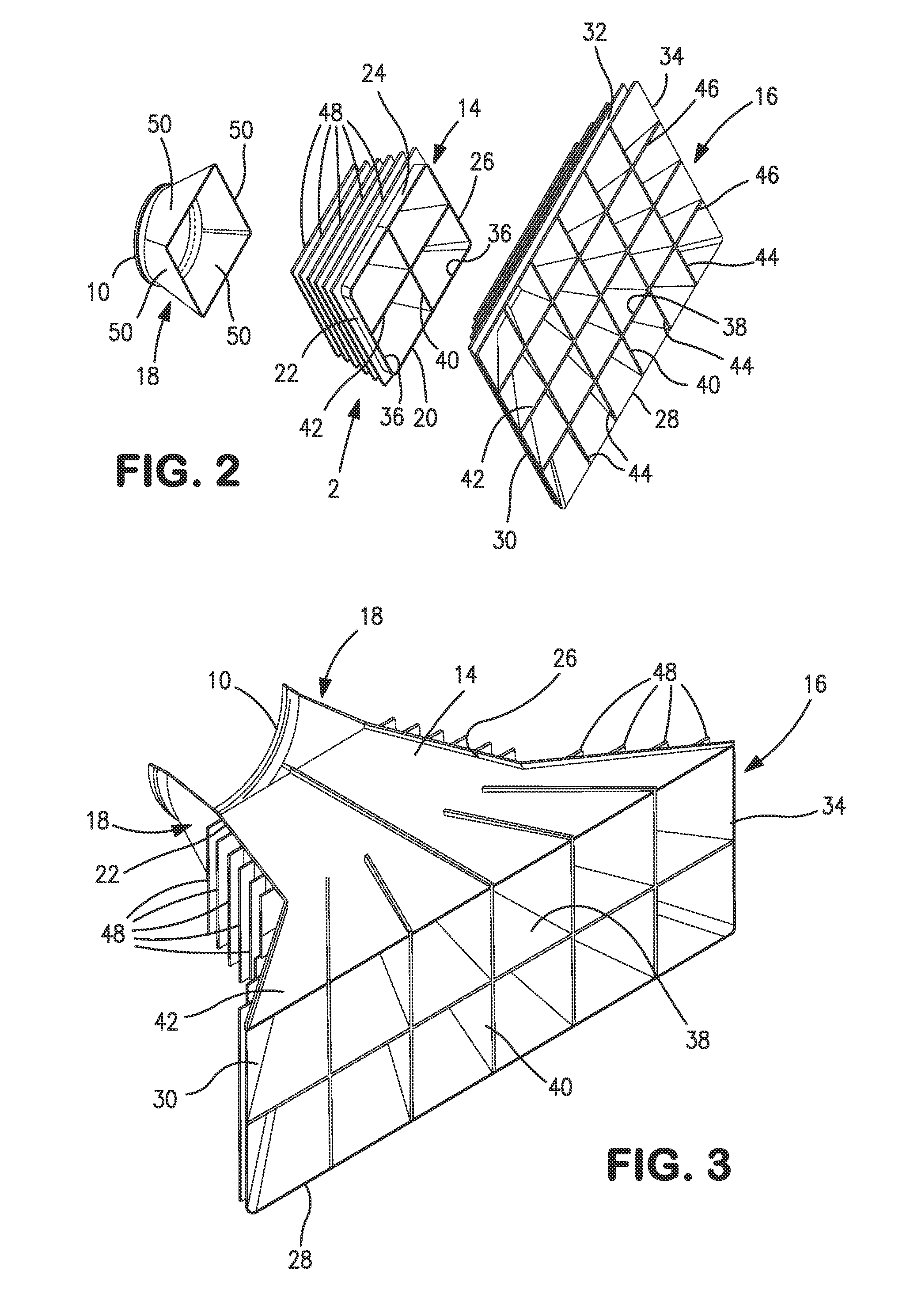

[0030]With reference to FIG. 1, a compressed gas cooling apparatus 1 in accordance with the present invention is illustrated. As mentioned above, such apparatus can function as an intercooler between compression stages or an after-cooler to cool the gas discharged from a compression stage to be used in downstream processing. Apparatus 1 has an inlet section 2, an outlet section 3 and a heat exchanger 4 connecting the inlet section 2 to the outlet section 3. The inlet section 2 has an inlet 10 to receive a gas flow “A” from an upstream compression stage, not illustrated. The upstream compression stage could be a centrifugal compressor or an axial compressor. In either case, the gas flow indicated by arrowhead “A” entering the inlet 10 has a swirl or a rotational component to the flow designated by curved arrowhead “B”. Such swirl is imparted to the flow by the rotational components of the compressor, for instance, the impeller of a centrifugal compressor.

[0031]The gas flow “A”, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com