Heat exchanger and method of manufacture thereof

a technology of heat exchanger and heat sealing section, which is applied in the direction of heat exchanger types, lighting and heating apparatus, laminated elements, etc., can solve the problems of heat sealing section separation, and achieve good heat transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

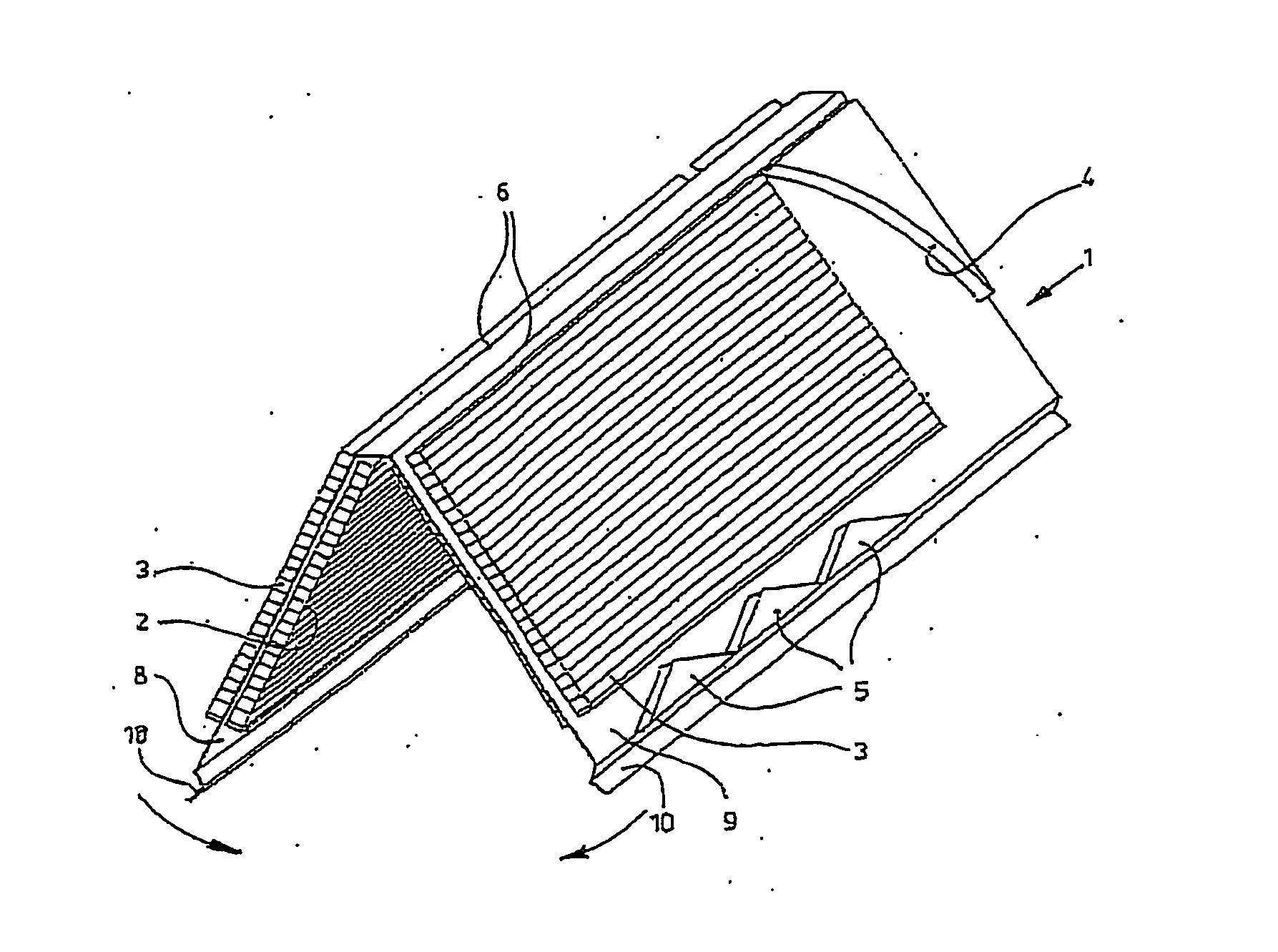

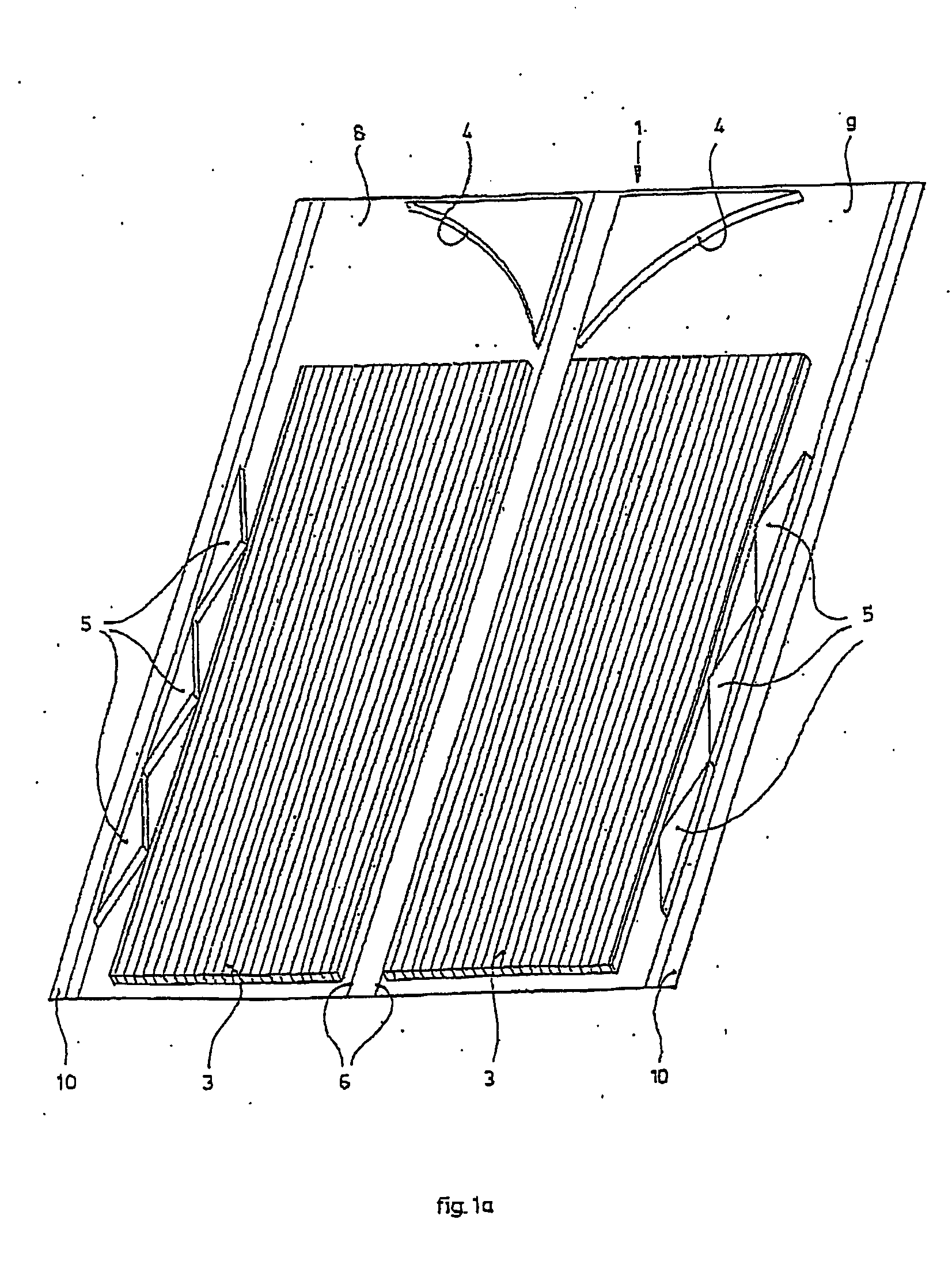

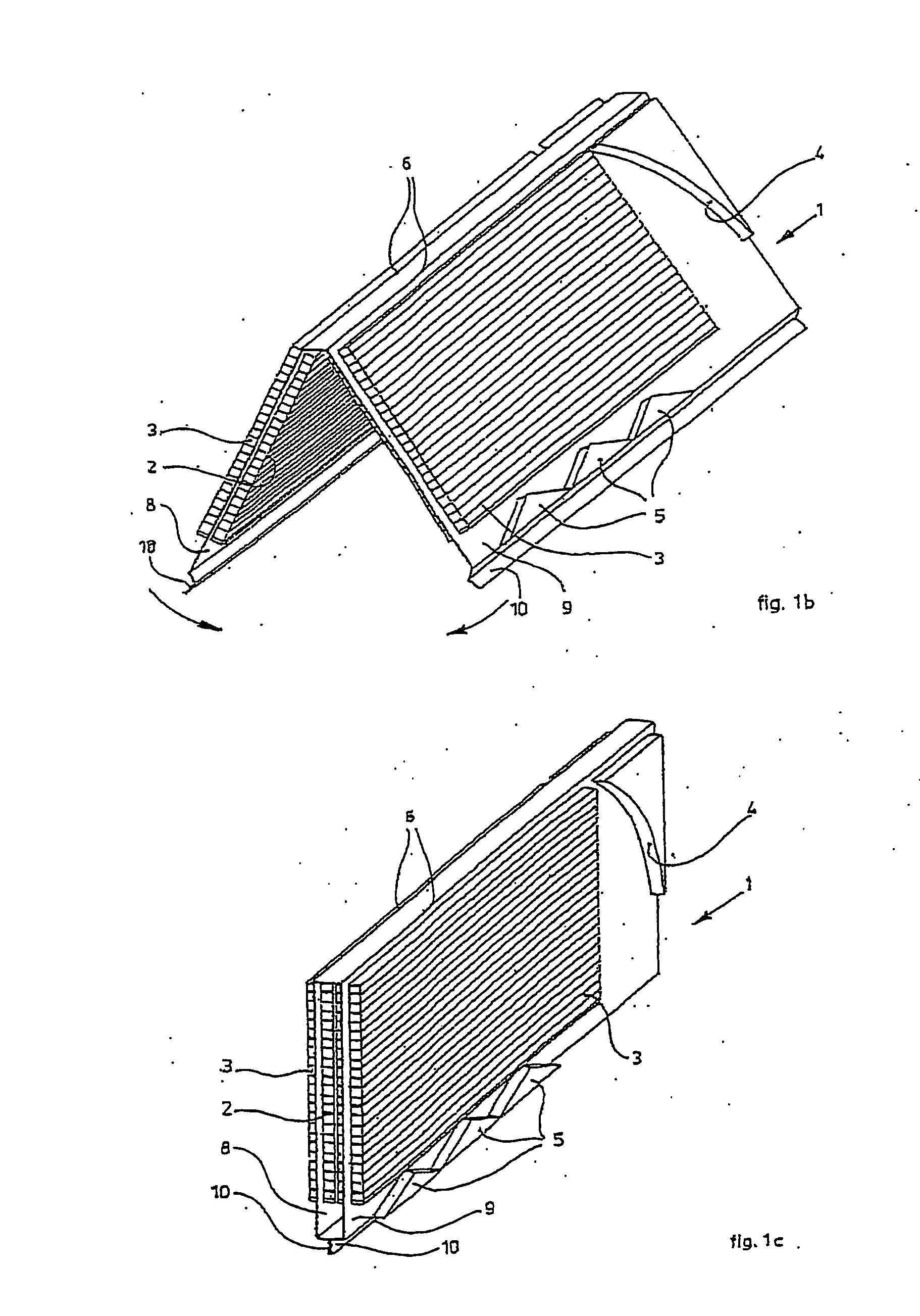

[0062]FIG. 1 shows a moulded sheet 1 consisting of a thin foil-like material of for instance polystyrene, PVC or PET. It is possible using such materials to apply a relatively small wall thickness, for instance in the order of 0.1 mm. Inexpensive production with a short throughput time is possible with for instance thermo-forming.

[0063] Sheet 1 is provided on both sides with schematically indicated packets of fins which, in FIG. 1, are designated 2 for the primary medium through-flow circuit and 3 for the secondary medium through-flow circuit.

[0064] Attention is drawn to the fact that the fins 2, 3 are shown very schematically. They consist in this embodiment of strips of limited length moulded in zigzag form in the longitudinal direction, i.e. the medium flow direction. This aspect is however not significant for the present invention.

[0065] Deflector dams 4 are formed in sheet 1 for deflecting the relevant medium flow. This aspect will be further elucidated with reference to FIG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com