Two row bent evaporator

a technology of evaporator and evaporator body, which is applied in the direction of ice removal, stationary conduit assembly, tubular elements, etc., can solve the problems of complex and costly communication manifolds, and achieve the effect of increasing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

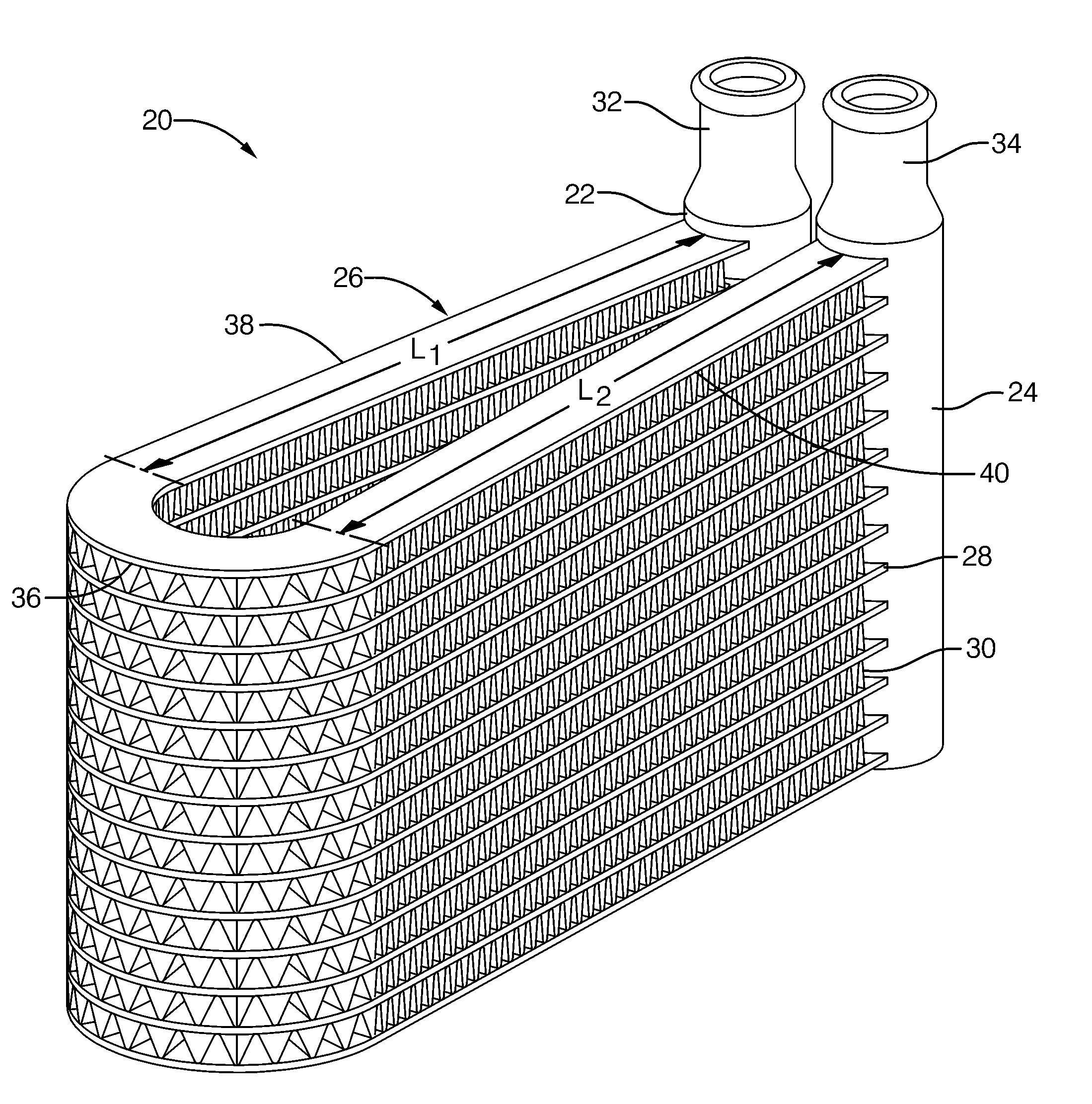

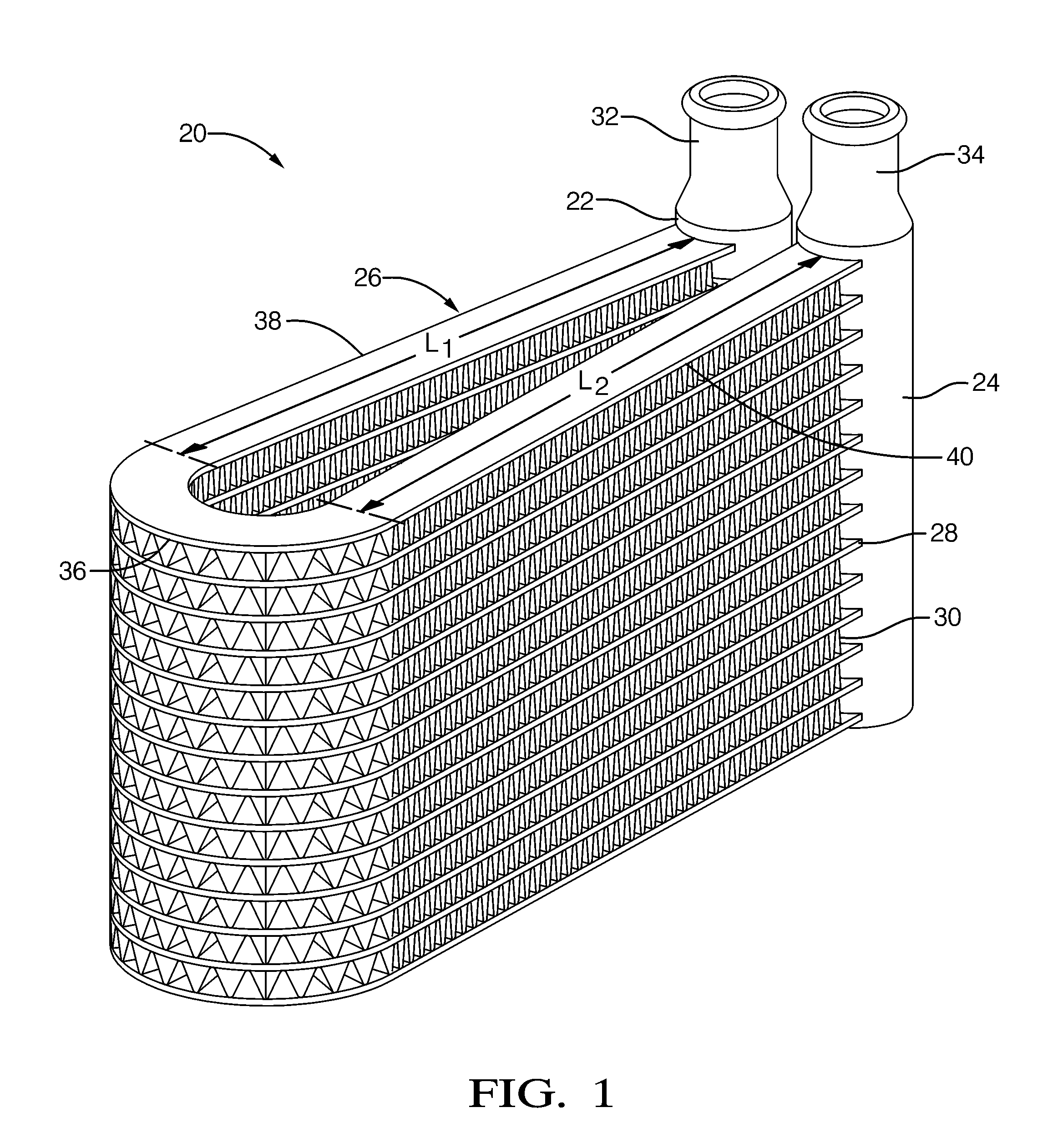

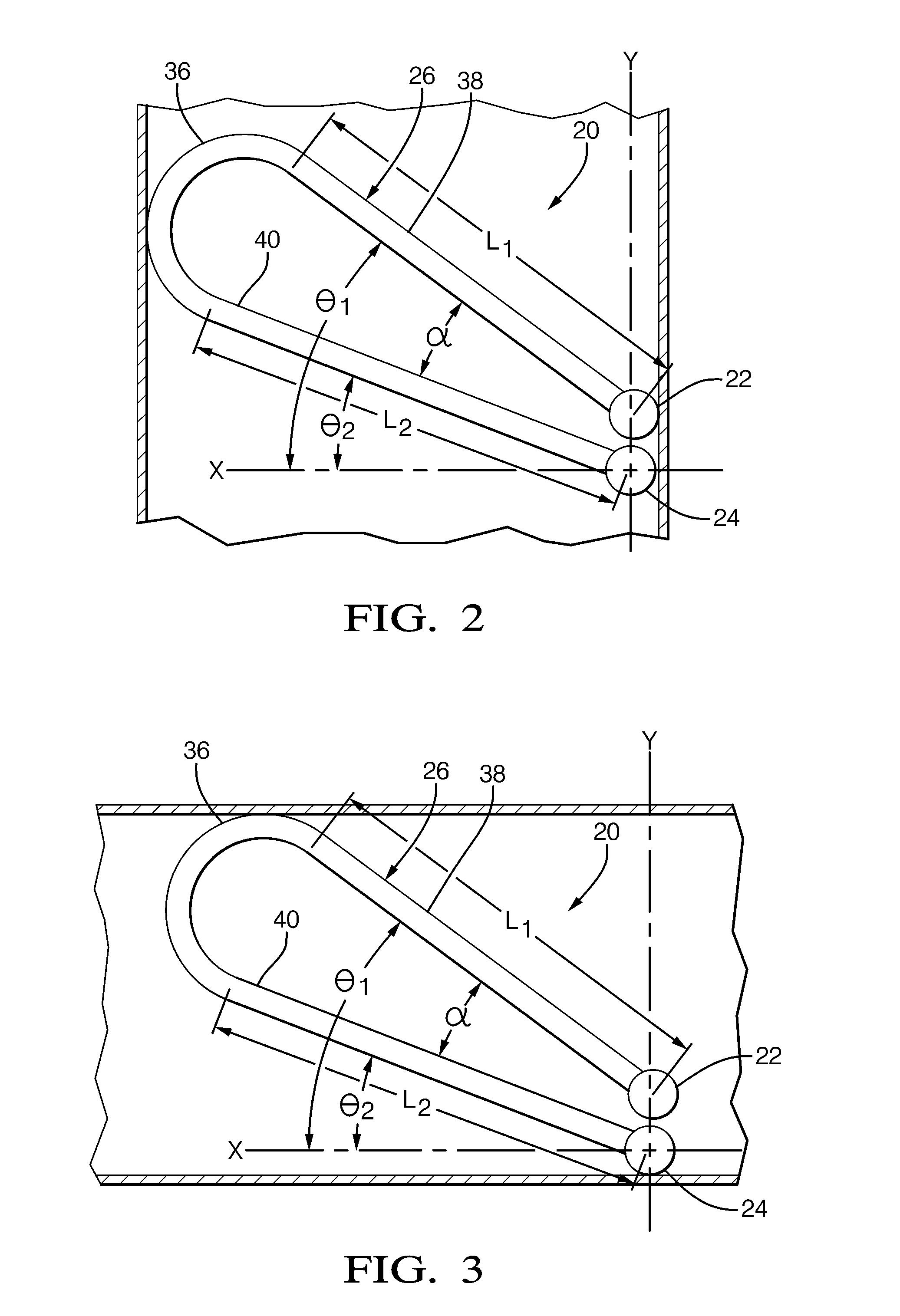

[0013]Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, the invention comprises a heat exchanger assembly 20 generally shown including an inlet manifold 22 and an outlet manifold 24 being cylindrical and extending in spaced and parallel relationship to one another. A core 26 extends between the manifolds 22, 24 for conveying a working fluid from the inlet manifold 22 to the outlet manifold 24, and includes a plurality of tubes 28 extending in spaced and parallel relationship to one another between the manifolds 22, 24. The core 26 also includes a plurality of air fins 30 extending back and forth between adjacent ones of the tubes 28 to present a serpentine pattern extending between the adjacent tubes 28. The inlet manifold 22 defines an inlet port 32 for receiving the working fluid, and the outlet manifold 24 defines an outlet port 34 for dispensing the working fluid.

[0014]The core 26 extends through a bend 36 to define a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com