Heat radiation material, heat radiation structure, and preparation method and application thereof

A technology of heat-dissipating materials and heat-dissipating structures, applied in heat-exchange materials, chemical instruments and methods, coatings, etc., can solve the problems affecting thermal conductivity and stability, poor compatibility between heat-dissipating fillers and polymer materials, and easy aggregation of nano-heat-dissipating materials and other problems, to achieve the effect of improving interface performance, excellent heat dissipation performance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

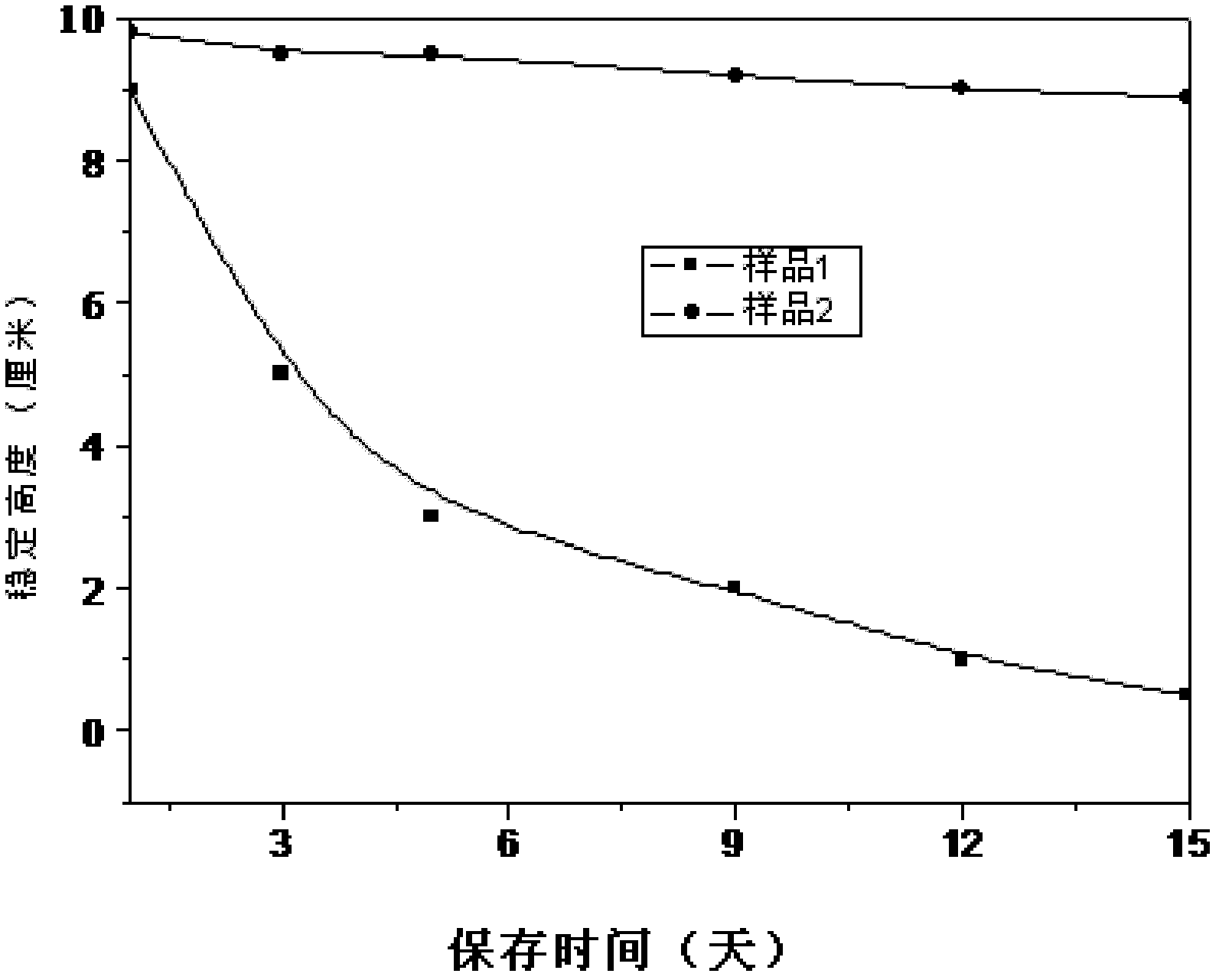

Embodiment 1

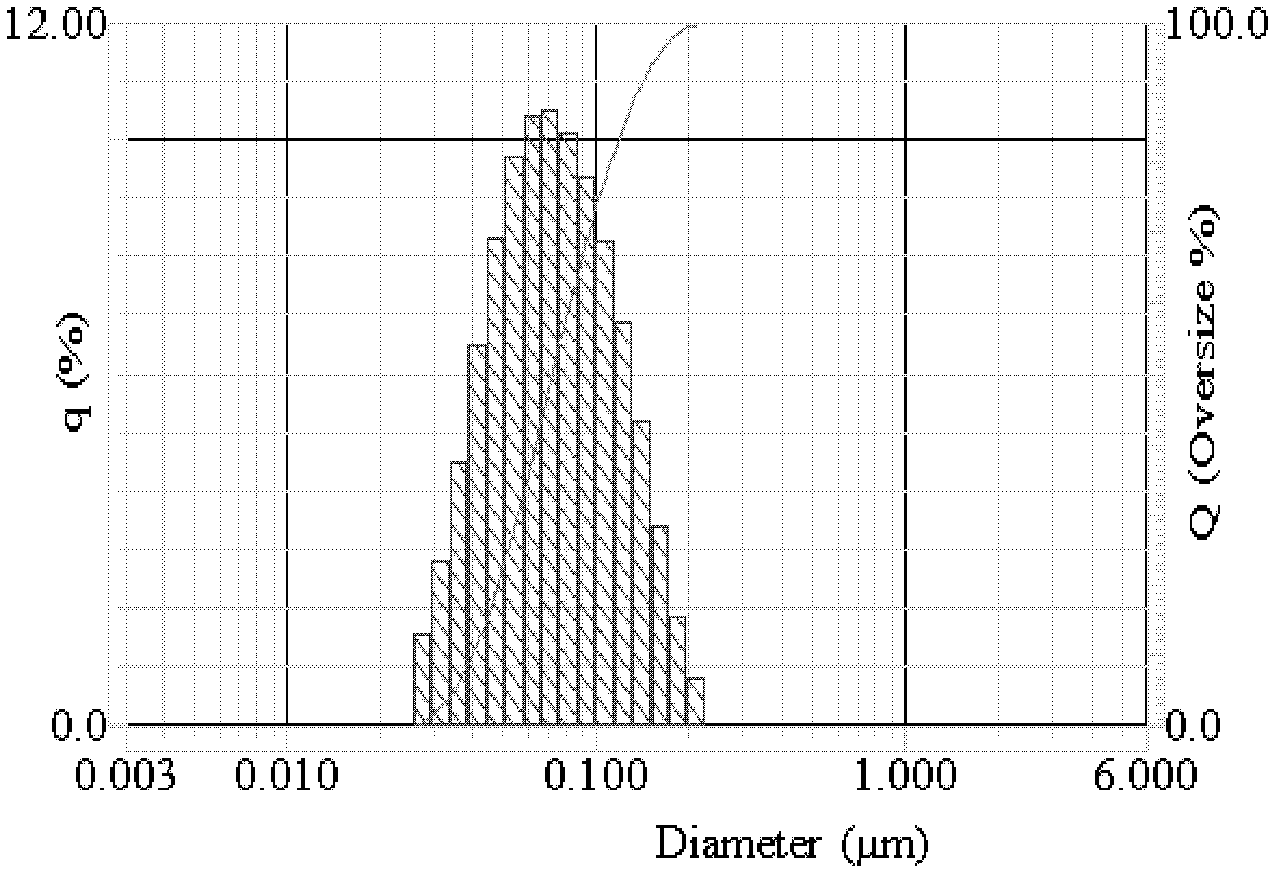

[0055] Under the protection of nitrogen, weigh 10g of 30-40nm hollow carbon nanospheres (HCNC) and place them in 50g of solvent water, ultrasonic wave at room temperature for 30min to disperse evenly; then under ultrasonic state, use 5% ammonia water to adjust the pH value To 8-10, then dropwise add 10g of modifying agent polyvinyl alcohol (Mw=2000) aqueous solution (concentration is 50wt%) at the speed of 3ml / min, continue ultrasonic wave 30min to disperse evenly after dropping; The heating rate of °C / min is raised to 60 °C. During this process, the remaining 5 g of the above modifier polyvinyl alcohol aqueous solution is added dropwise at a rate of 3 ml / min. When the temperature is raised to 60 °C, the dropwise addition is completed. React for 4 hours, then disperse for 60 minutes with an ultra-high pressure nano homogenizer, and disperse for 60 minutes with an ultrasonic wave to obtain a uniformly dispersed inorganic heat-dissipating nanomaterial water-based slurry.

Embodiment 2

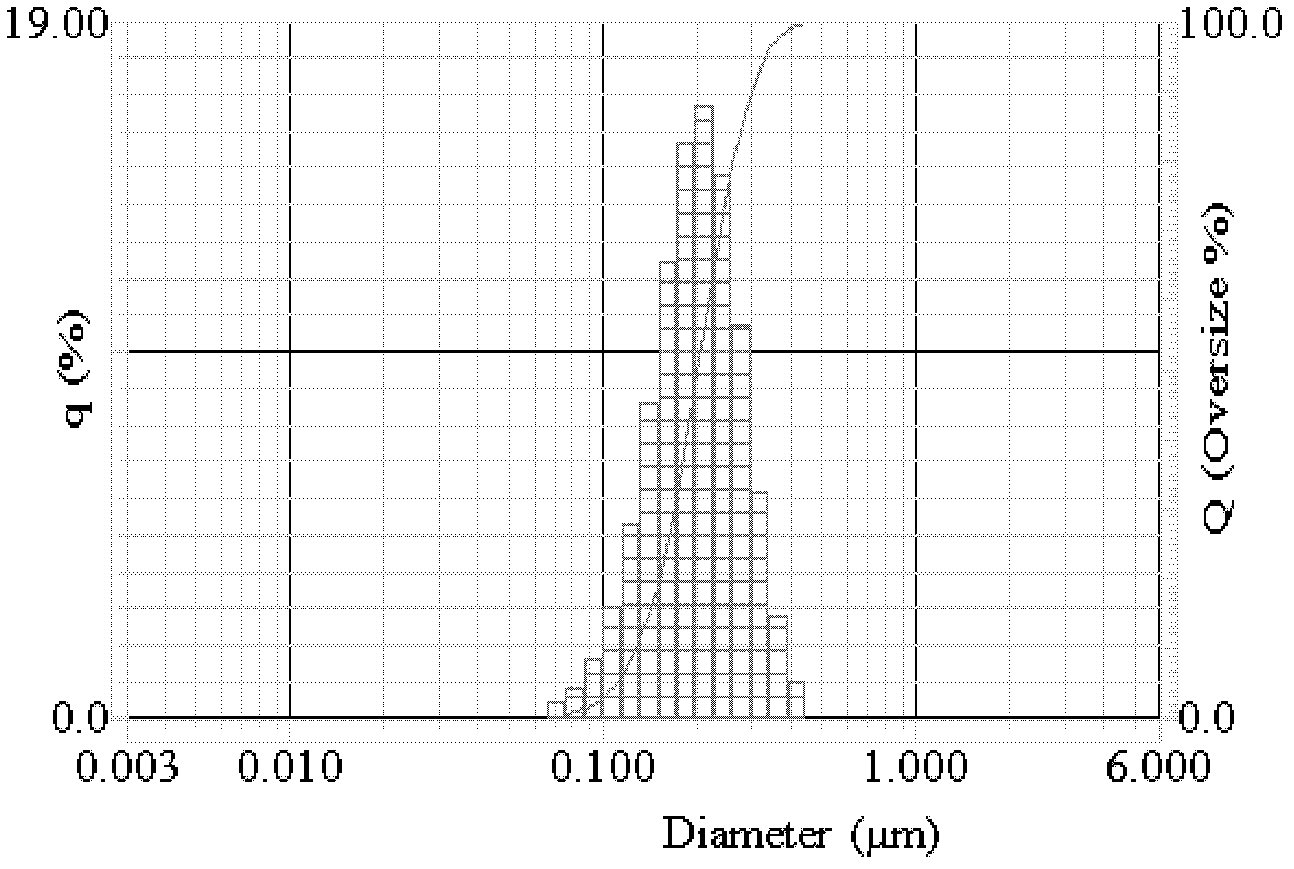

[0057] Under the protection of nitrogen, weigh 10g of 10-30nm carbon nanotubes (product label: IMC4, the same below) and place them in 100g of solvent water, and use ultrasonic wave at room temperature for 30min to disperse evenly; then in the ultrasonic state, use 5% Adjust the pH value to 8-10 with ammonia water, then add 10g of modifying agent polyvinyl alcohol (Mw=2000) aqueous solution (concentration is 50wt%) dropwise at a speed of 4ml / min, continue ultrasonic wave for 30min to disperse Uniform; then raise the temperature to 50°C at a heating rate of 3°C / min, add the remaining 5g of the above modifier polyvinyl alcohol aqueous solution dropwise at a rate of 4ml / min during this process, and complete the dropwise addition when the temperature rises to 50°C , react at this temperature for 6 hours, then disperse for 60 minutes with an ultra-high pressure nano homogenizer, and disperse with an ultrasonic wave for 60 minutes to obtain a uniformly dispersed inorganic heat-dissip...

Embodiment 3

[0059] Under the protection of nitrogen, weigh 25g of 30nm nano-aluminum nitride (product label: DK331, the same below) and place it in 75g of solvent water, and use ultrasonic wave at room temperature for 20min to disperse evenly; then under ultrasonic state, use 5% Ammonia adjusts the pH value to 8, then drips 12g of modifying agent polyacrylic acid (Mw=3000) aqueous solution (concentration is 50wt%) with the speed of 2ml / min, continues ultrasonic wave 15min to disperse evenly after dropping; Raise the temperature to 60°C at a heating rate of 3°C / min. During this process, drop the remaining 6g of the above modifier polyacrylic acid aqueous solution at a rate of 2ml / min. When the temperature rises to 60°C, the dropwise addition is completed. React for 3 hours, then disperse for 120 minutes with an ultra-high pressure nano-homogenizer, and disperse for 90 minutes with an ultrasonic wave to obtain a uniformly dispersed inorganic heat-dissipating nanomaterial water-based slurry. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com