Polyacrylamide composite flocculant and preparation method thereof

A polyacrylamide and composite flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. In order to achieve the effect of enhancing the interface effect, reducing the cost, and realizing the synergistic and efficient flocculation of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

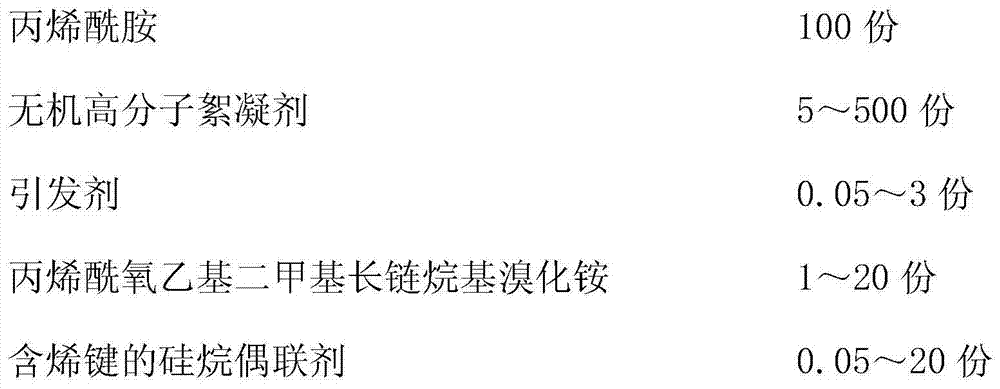

Method used

Image

Examples

Embodiment 1

[0023] Disperse 20g of polyaluminum chloride in 1000mL of ethanol / water mixture with a volume ratio of 6 / 1, stir at 60°C for 1 hour, then add 2g of vinyltriethoxysilane, continue stirring for 3 hours, and filter the product with suction And after washing twice, vacuum-dry at 80°C;

[0024] Disperse 10g of surface-treated polyaluminum chloride in 200mL of water for 5 minutes of ultrasonic dispersion, the ultrasonic power is 200W; Solution, drop 100mL of polyaluminum chloride dispersion solution, raise the temperature to 50°C, pass N 2 , add 0.1g of initiator, stir evenly, react for 4h; cool the product to room temperature, wash with acetone precipitation, and vacuum dry at 40°C for 6h to obtain polyacrylamide in-situ composite flocculant.

Embodiment 2

[0026] Disperse 40g of polyaluminum silicate in 3000mL of ethanol / water mixture with a volume ratio of 6 / 1, stir at 60°C for 1 hour, then add 8g of vinyl-tris(β-methoxyethoxy)silane, Stirring was continued for 3 hours, and the product was vacuum-dried at 80°C after suction filtration and washing twice;

[0027] Disperse 20g of surface-treated polyaluminum silicate in 1000mL of water for 5 minutes of ultrasonic dispersion, the ultrasonic power is 200W; Mass concentration solution, dropwise add 200mL of polyaluminum silicate dispersion solution, heat up to 60°C, pass N 2 , add 0.5g of initiator, stir evenly, react for 5h; cool the product to room temperature, wash with acetone precipitation, and vacuum dry at 40°C for 6h to obtain polyacrylamide in-situ composite flocculant.

Embodiment 3

[0029] Disperse 60g of polyaluminum ferric chloride in 2000mL of ethanol / water mixture with a volume ratio of 6 / 1, stir at 60°C for 1 hour, then add 16g of γ-propylmethacrylate trimethoxysilane, and continue stirring for 3 hour, the product was vacuum-dried at 80° C. after being filtered and washed twice;

[0030] Disperse 40g of surface-treated polyaluminum ferric chloride in 2000mL of water for ultrasonic dispersion for 5 minutes, and the ultrasonic power is 200W. Dissolve 100g of acrylamide and 15g of acryloyloxyethyldimethyltetradecylammonium bromide in water to prepare a solution with a mass concentration of 35%, add dropwise 400mL of polyaluminum ferric chloride dispersion solution, heat up to 80°C, and pass N 2 , add 1.2g of initiator, stir evenly, react for 6h; cool the product to room temperature, wash with acetone precipitation, and vacuum dry at 40°C for 6h to obtain polyacrylamide in-situ composite flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com