Oil displacement composition containing betaine type surfactant and application thereof

A surfactant and composite surfactant technology, applied in the field of chemical flooding formula system, can solve the problems of high technical and economic risks, and the basic research of binary compound flooding needs to be strengthened, so as to achieve enhanced recovery, good adsorption and stable performance , Excellent oil displacement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

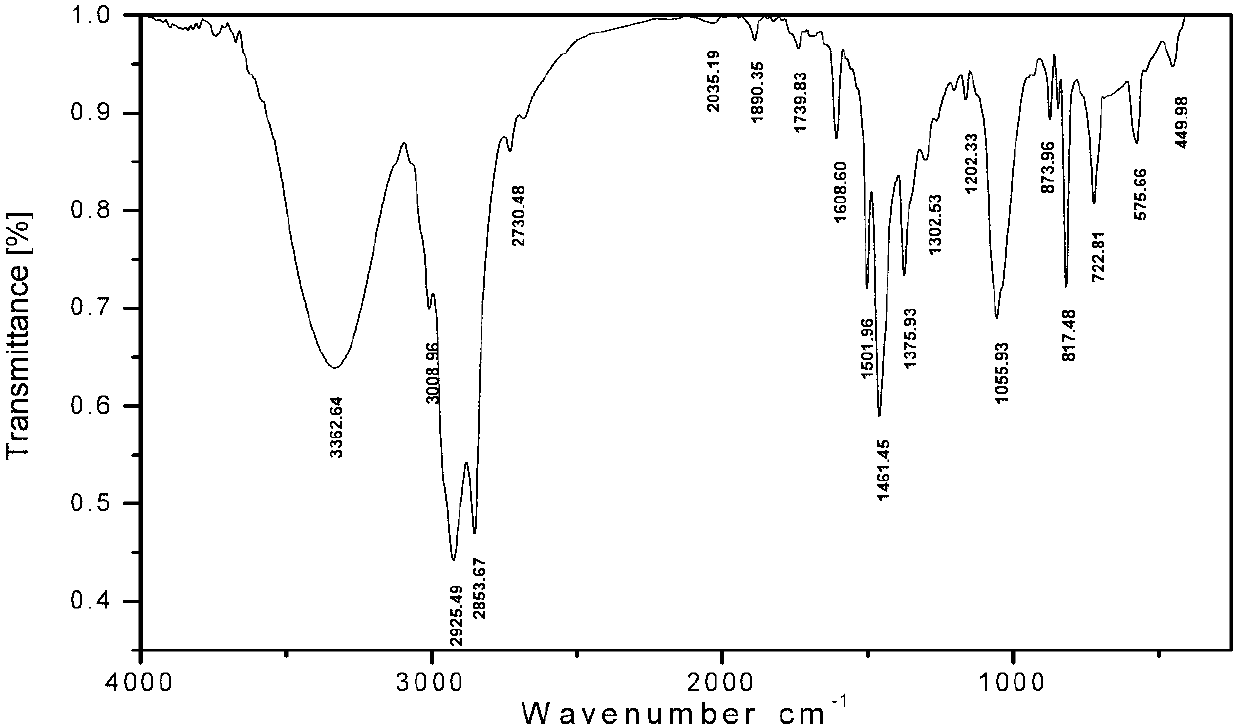

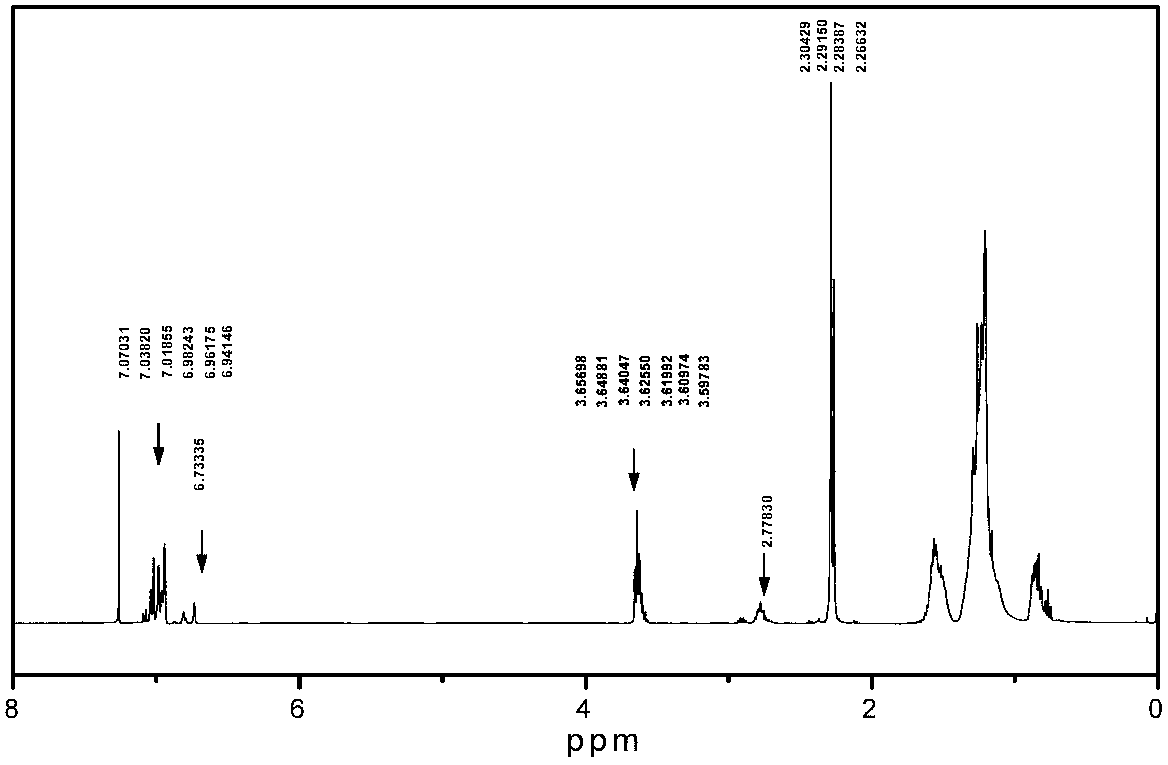

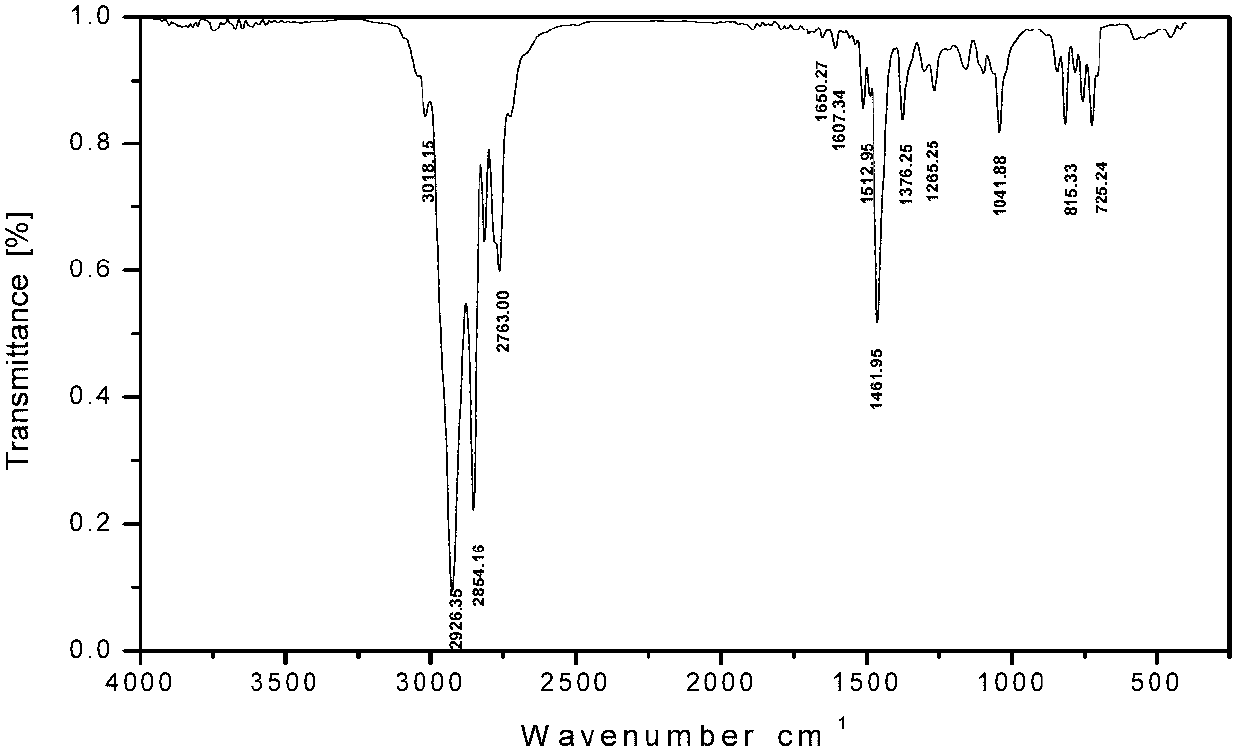

[0090] Example 1 Synthesis and identification of betaine type surfactants and aryl alkyl alcohol polyoxyethylene ether nonionic surfactants

[0091] The detailed reaction steps of betaine surfactants are as follows:

[0092] (1) Esterification reaction: mix oleic acid and methanol (excess methanol), add catalyst concentrated sulfuric acid or p-toluenesulfonic acid, and heat to reflux for 10 hours. Cool, neutralize with sodium methoxide to a pH of 8-9, wash with water to neutrality, dry with anhydrous calcium chloride and distill under reduced pressure to obtain methyl oleate;

[0093] (2) Fu's alkylation: Add meta-xylene and other organic proton acid catalysts (such as methanesulfonic acid) in a 2.5L sealed reactor, add dropwise at 115~120℃, 0.2MPa The reaction product methyl oleate of step (1) with 5 times the amount of substance, the dripping time is controlled at 6h, after the dripping is completed, the reaction is continued for 3h. Static stratification, the lower catalyst deco...

Embodiment 2

[0113] Example 2 Determination of dynamic interfacial tension of oil-water in Daqing Oilfield No. 1 Plant by a formulation system containing betaine surfactants and aryl alkyl alcohol polyoxyethylene ether nonionic surfactants

[0114] Polyacrylamide HPAM, produced by Daqing Refining & Chemical Company, has a degree of hydrolysis of about 20% and an average molecular weight of 19 million.

[0115] The interfacial tension test adopts TEXAS-500C rotating drop interfacial tension meter, the interfacial tension test temperature is 45℃, the interfacial tension test time is 2 hours, and the crude oil from Daqing No. 1 Factory.

[0116] Formula system containing betaine surfactant and aryl alkyl alcohol polyoxyethylene ether nonionic surfactant: composite surfactant 0.025%~0.3%, polymer HPAM 0.15%, and the rest is injection water from Daqing No. 1 Plant ;

[0117] Among the composite surfactants,

[0118] Betaine type surfactants are

[0119] m+n=15;

[0120] Aryl alkyl alcohol polyoxyethylene...

Embodiment 3

[0124] Example 3 Determination of the emulsification performance of the formulation system containing betaine surfactants and alkyl alcohol polyoxyethylene ether nonionic surfactants on the oil and water of the No. 1 and No. 6 plants of Daqing Oilfield

[0125] Polyacrylamide HPAM, produced by Daqing Refining & Chemical Company, has a degree of hydrolysis of about 20% and an average molecular weight of 19 million.

[0126] Emulsification performance test method: Put the binary system to be tested and crude oil 1:1 volume ratio in a test tube with a stopper, use a homogenizer to emulsify (rotate at 10000rpm) for 1 min, and determine the final water separation rate as a preliminary index for evaluating emulsification performance. The actual emulsification effect of Bailey core flooding experiment is used to evaluate the emulsification performance.

[0127] Formula system containing betaine surfactant and aryl alkyl alcohol polyoxyethylene ether nonionic surfactant: composite surfactant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com