Method for preparing lithium iron phosphate as lithium ion cell positive-pole material

A lithium ion battery, lithium iron phosphate technology, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of complex surface compounding and large interface resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of lithium iron phosphate, a cathode material for lithium ion batteries, uniformly mixing lithium dihydrogen phosphate and ferrous oxalate, controlling the molar ratio of phosphorus, iron and lithium in the raw materials to be 1.0:1.0:1.0, using argon as a protective atmosphere , heating up to 530°C within 3 hours, keeping the temperature for 6 hours, and then cooling to room temperature to obtain a pure phase of lithium iron phosphate;

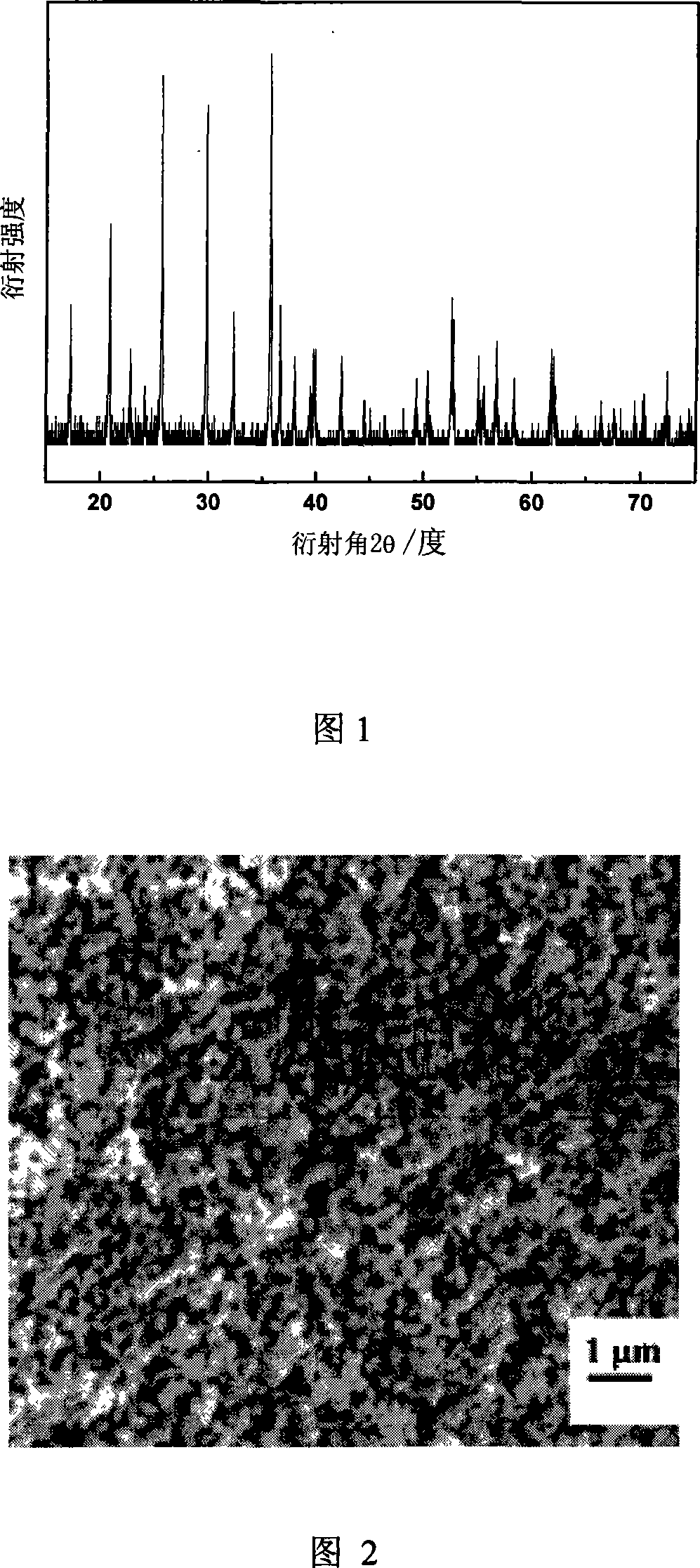

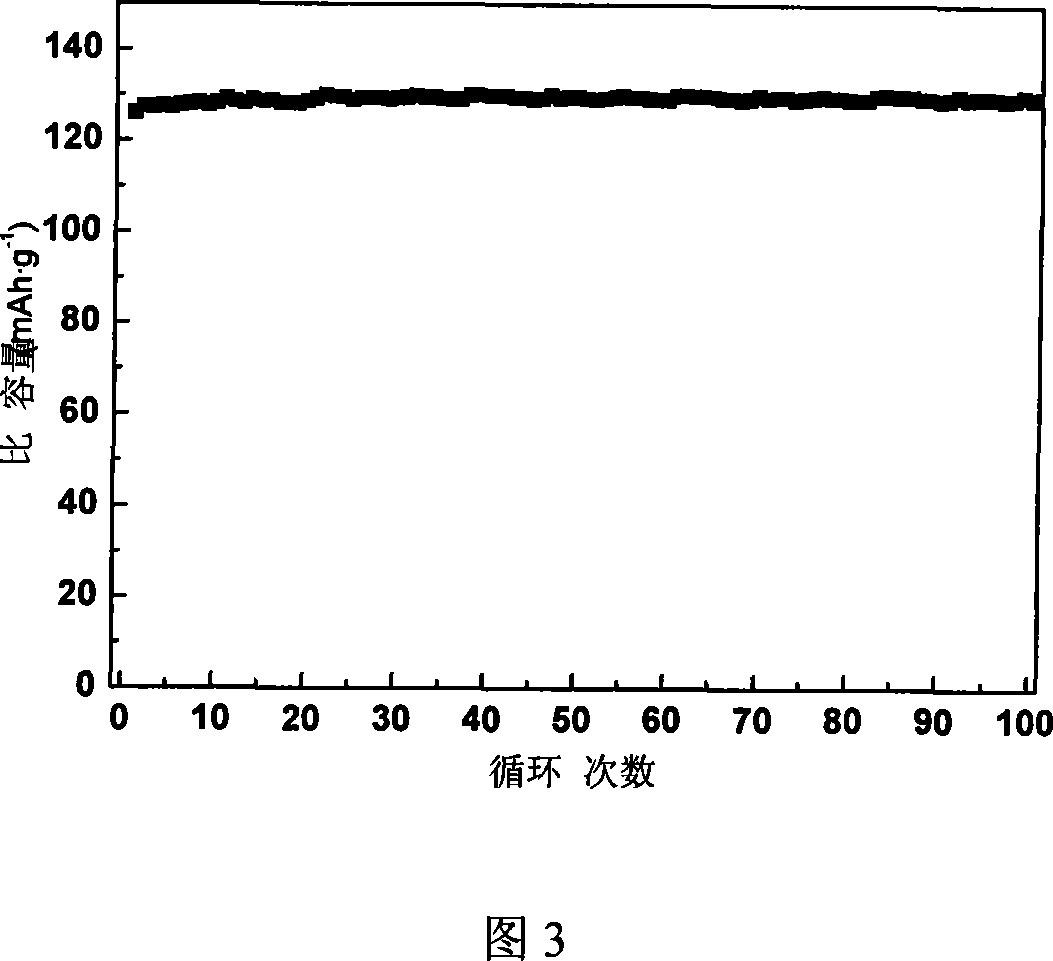

[0020] Add inorganic conductive and ultrafine carbon black and carbon-containing conductive agent precursor sucrose in the pure phase of lithium iron phosphate, the addition of carbon black is 5% of the weight of lithium iron phosphate, and the addition of sucrose is 5% of the weight of lithium iron phosphate , after fully mixing, heat treatment at 850°C for 15 minutes, and the output is the positive electrode material lithium iron phosphate. Fig. 1 is an X-ray diffraction pattern, and the obtained lithium iron pho...

Embodiment 2

[0024] A preparation method of lithium iron phosphate, a cathode material for lithium ion batteries, uniformly mixes ferrous oxide, lithium oxide, and phosphorus pentoxide, controls the molar ratio of phosphorus, iron, and lithium in the raw materials to be 1.0:0.85:1.00, and uses nitrogen as the In a protective atmosphere, heat up to 600°C within 5 hours, keep the temperature for 8 hours, and then cool to room temperature to obtain a pure phase of lithium iron phosphate;

[0025] Addition of conductive boride MgB in pure phase of lithium iron phosphate 2 and MoB 2 , MgB 2 The amount added is 15% of the weight of lithium iron phosphate, MoB 2 The added amount is 5% of the weight of lithium iron phosphate. After fully mixing, heat treatment at 800° C. for 1 hour, and the output is the positive electrode material lithium iron phosphate.

Embodiment 3

[0027] A preparation method of lithium iron phosphate, a cathode material for lithium ion batteries, uniformly mixes lithium phosphate and iron hydroxide, controls the molar ratio of phosphorus, iron and lithium in the raw materials to be 1.0:0.95:1.00, uses hydrogen and argon as a protective atmosphere, and Raise the temperature to 700°C within 6 hours, keep the temperature for 5 hours, and then cool to room temperature to obtain a pure phase of lithium iron phosphate;

[0028]In the pure phase of lithium iron phosphate, a composite conductive agent composed of conductive carbide TiC and carbon-containing conductive agent precursor gelatin and ethylene glycol is added. The addition of TiC is 1% of the weight of lithium iron phosphate, and the addition of gelatin is The weight of lithium is 2%, and the amount of ethylene glycol added is 8% of the weight of lithium iron phosphate. After fully mixing, heat treatment at 1000° C. for 0.1 hour, and the output is the positive electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com