Method of chemically-grafting graphene oxide onto surface of carbon fiber

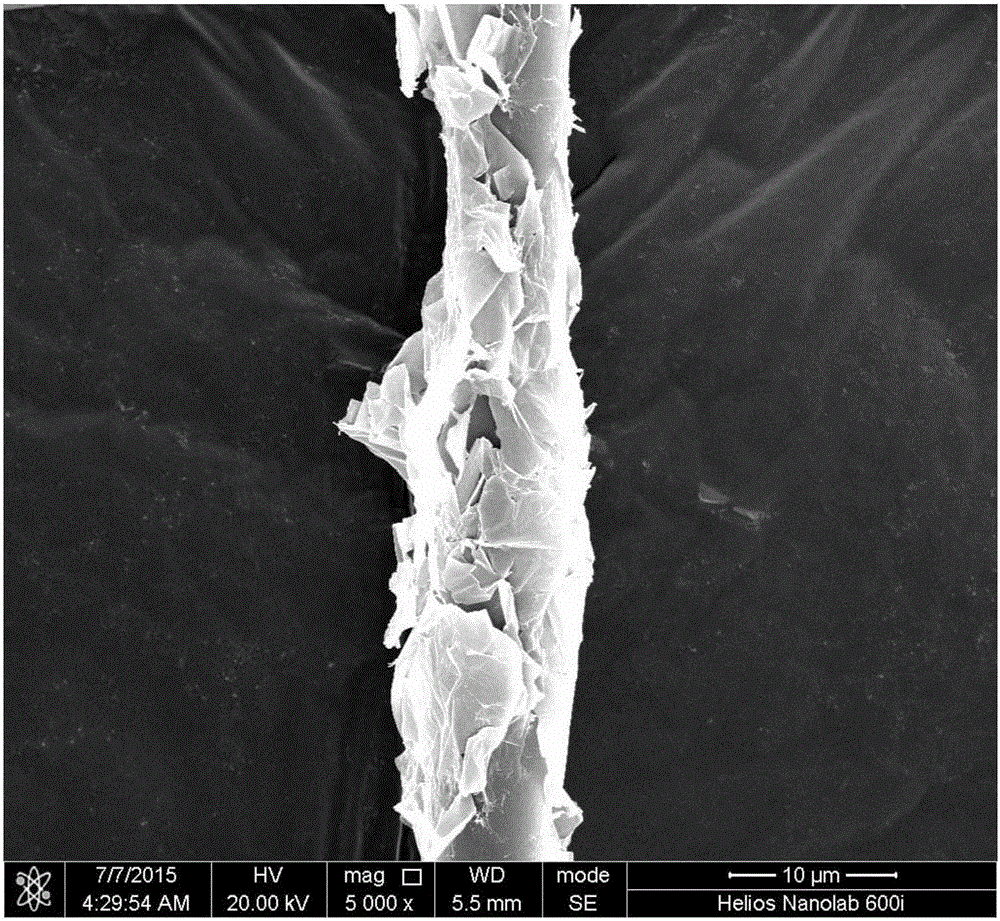

A surface chemistry, carbon fiber technology, used in carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of carbon fiber surface inertness, low surface energy, poor thermal properties, etc., to improve the interface bonding quality and surface roughness increase , Improve the effect of surface wettability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

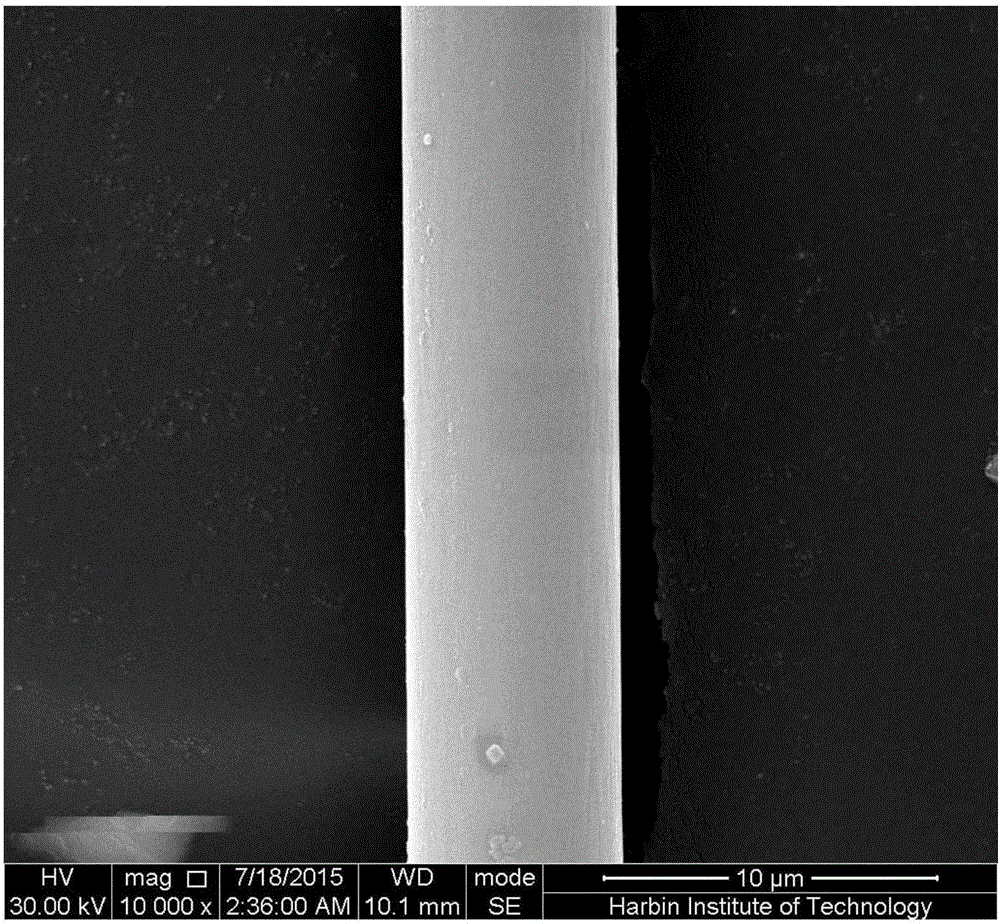

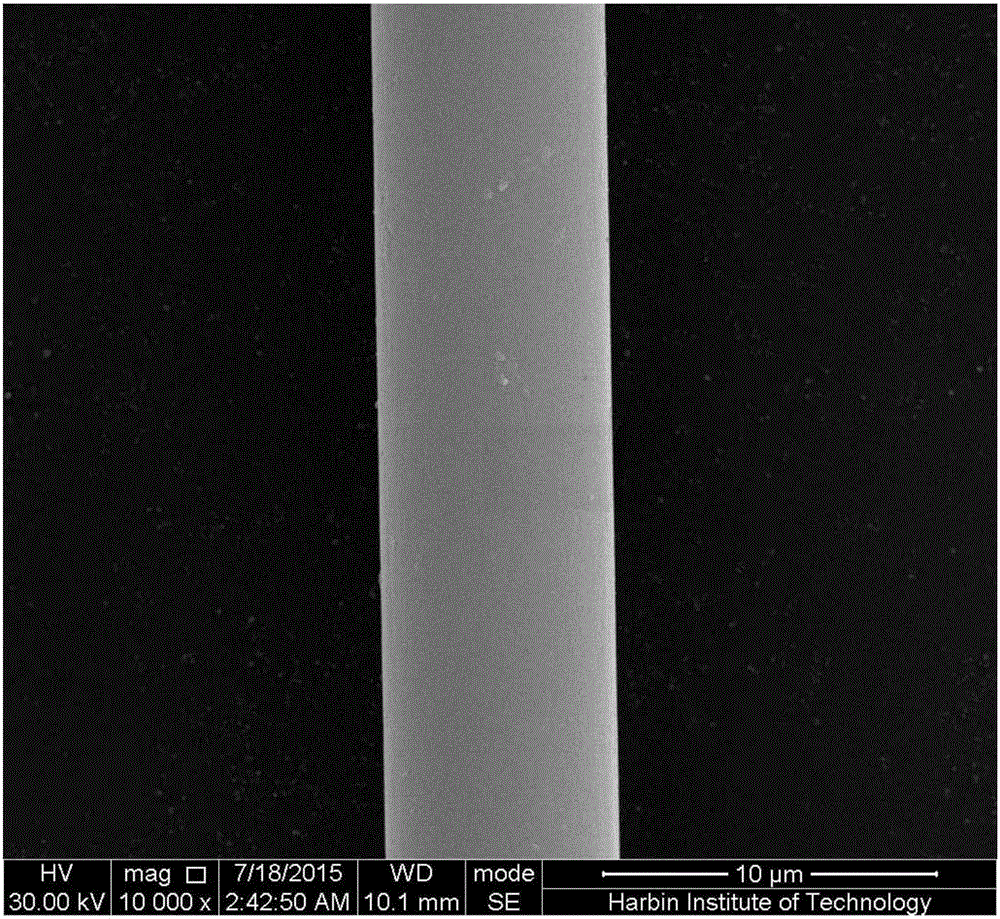

[0027] Specific embodiment one: the method for chemically grafting graphene oxide on the surface of carbon fiber in this embodiment is carried out in the following steps:

[0028] 1. Prepare graphene oxide by improving Hummer's method:

[0029] a. Under the condition of ice-water bath, graphite powder and concentrated H with a mass concentration of 98% were successively 2 SO 4 、NaNO 3 and KMnO 4 Add it into a round-bottom flask and stir, heat up to 35°C, react for 7 hours, cool down, put it in an ice-water bath, and then add concentrated H with a mass concentration of 98% to the round-bottom flask 2 SO 4 and KMnO 4 , heated up to 35°C, and reacted for 12h;

[0030] b. Stop the reaction, add ice water to the round bottom flask, stir, pour into a large beaker, add H 2 o 2 until the color of the solution changes from dark brown to bright yellow, repeatedly washing with HCl and deionized water with a volume concentration of 5% to neutrality, and freeze-drying to obtain gra...

specific Embodiment approach 2

[0038] Specific embodiment two: this embodiment is different from specific embodiment one: the graphite powder described in step one a and the mass concentration that adds for the first time are the concentrated H of 98% 2 SO 4 The mass ratio is 1:40~50; the graphite powder and NaNO3 The mass ratio of is 2:1; Described graphite powder and the KMnO that add for the first time 4 The quality is 1:3. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: this embodiment is different from specific embodiment one or two: the graphite powder described in step one a and the mass concentration that adds for the second time are the concentrated H of 98% 2 SO 4 The mass ratio of the graphite powder is 1:8~11; the graphite powder and the KMnO added for the second time 4 The quality is 1:1~1.5. Others are different from the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com