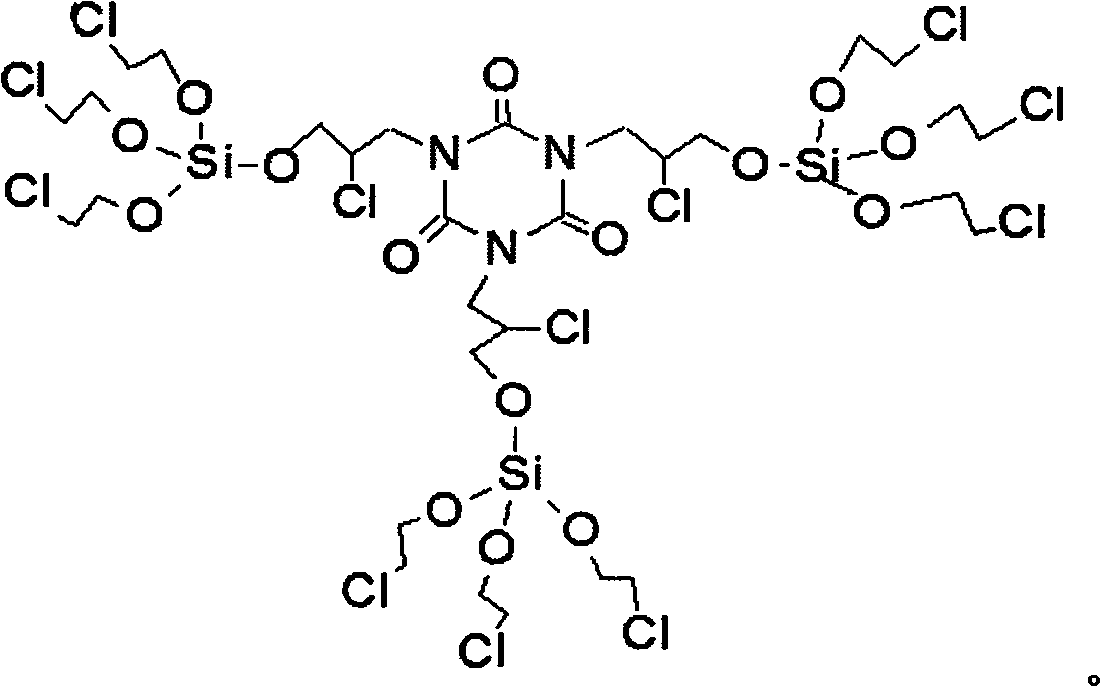

Isocyanurate chloropropyl chloroethyl silicate and preparation method thereof

A technology of isocyanurate and isocyanuric acid tri, which is applied in the field of flame-retardant plasticizers, can solve the problems of limited use, narrow use range, and high price, and achieve good plasticization, low cost, and environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

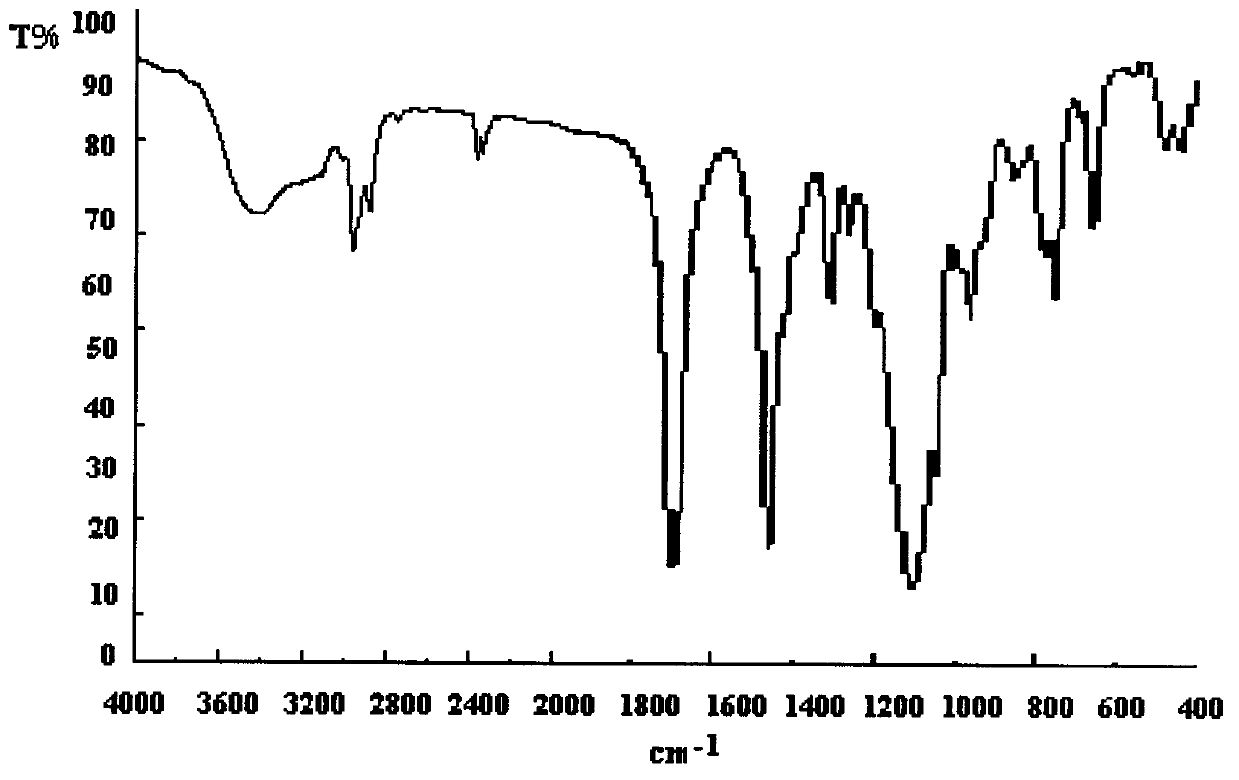

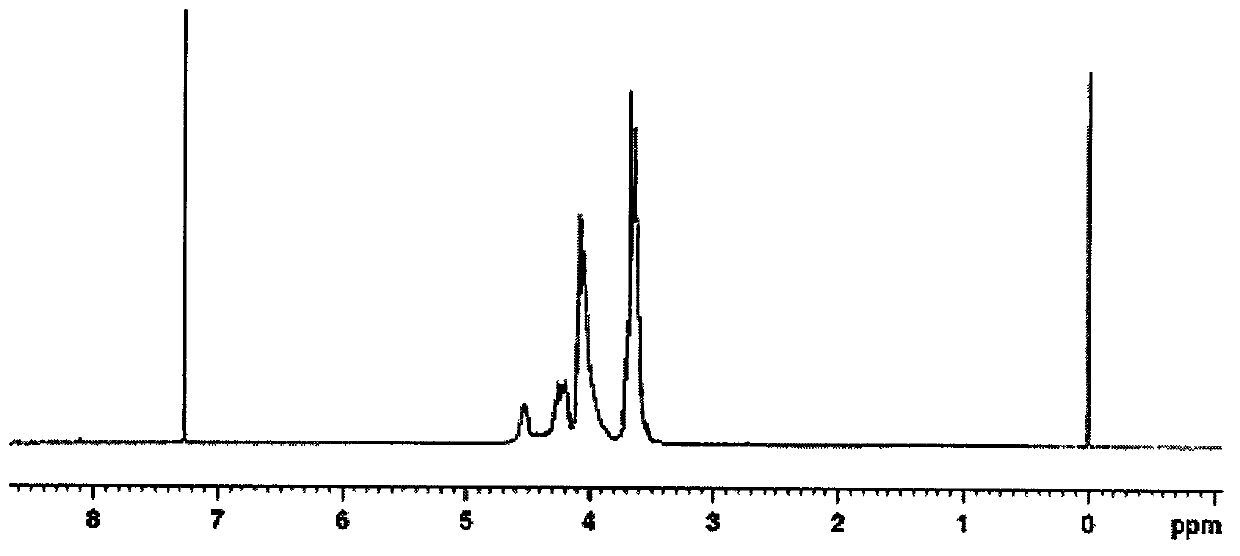

[0025] Example 1 In a 100ml three-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, add 10ml of acetonitrile, use nitrogen to exhaust the air in the bottle, and accurately draw 3.40ml (0.03mol) of SiCl 4 Placed in a three-neck bottle. Weigh 3.00g (0.01mol) of triglycidyl isocyanurate and dissolve it in 40ml of acetonitrile. Add the solution dropwise into a three-necked flask at 20°C for about 0.5h. Then lower the temperature to 30°C, install an extremely flexible and expandable soft sealing sleeve on the upper mouth of the high-efficiency reflux condenser, and inject 3.96g (0.09mol) of ethylene oxide under the liquid surface, and the temperature of the feeding process should not be higher than 40°C. Then heat up to 55°C for 3 hours of heat preservation reaction, and check that the pH of the reaction solution is at 5-6 as the end point. After the reaction is over, the solvent and low boiling point substances are distilled off under reduce...

Embodiment 2

[0026] Example 2 In a 100ml three-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, add 10ml of tetrahydrofuran, use nitrogen to drive out the air in the bottle, and accurately draw 3.40ml (0.03mol) of SiCl 4 Placed in a three-neck bottle. Weigh 3.00g (0.01mol) of triglycidyl isocyanurate and dissolve it in 40ml of tetrahydrofuran. Add the solution dropwise into a three-necked flask at 20°C for about 0.5h. Then lower the temperature to 30°C, install an extremely flexible and expandable soft sealing sleeve on the upper mouth of the high-efficiency reflux condenser, and inject 4.40g (0.10mol) of ethylene oxide under the liquid surface, and the temperature of the feeding process should not be higher than 40°C. Then heat up to 50°C for 3 hours of heat preservation reaction, and check that the pH of the reaction solution is at 5-6 as the end point. After the reaction is over, the solvent and low boiling point substances are distilled off unde...

Embodiment 3

[0027] Example 3 In a 100ml three-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, add 10ml of dioxane, use nitrogen to drive out the air in the bottle, and accurately draw 3.40ml (0.03mol) of SiCl 4Placed in a three-neck bottle. Weigh 3.00g (0.01mol) of triglycidyl isocyanurate and dissolve it in 40ml of dioxane, add the solution dropwise into a three-necked flask at 20°C for about 0.5h, and raise the temperature to 60°C for reaction 5h, then lower the temperature to 30°C, install an extremely flexible and inflatable soft sealing sleeve on the upper mouth of the high-efficiency reflux condenser, and inject 4.84g (0.11mol) of ethylene oxide under the liquid surface, and the temperature of the injection process should not be higher than 40 ℃, then heat up to 45 ℃ for 2 hours, and check that the pH of the reaction solution is at 5-6. Oxygen)silyloxy]propyl}isocyanurate, yield rate: 96.3%, flash point (open cup): 214±5°C, decomposition te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com