Corona resistant composition and preparation method thereof

A technology of corona resistance and composition, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of easy agglomeration, limit the corona resistance performance of corona resistant compositions, and achieve uniform distribution and good mechanical properties. performance, the effect of good corona resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

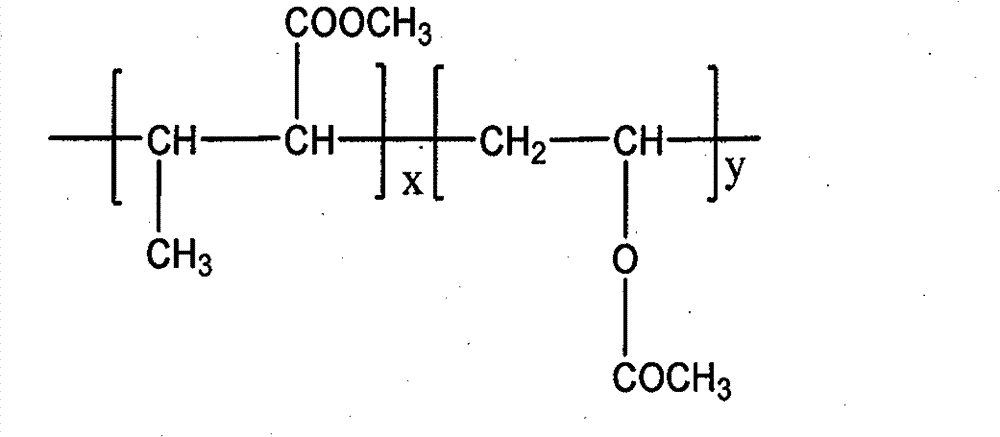

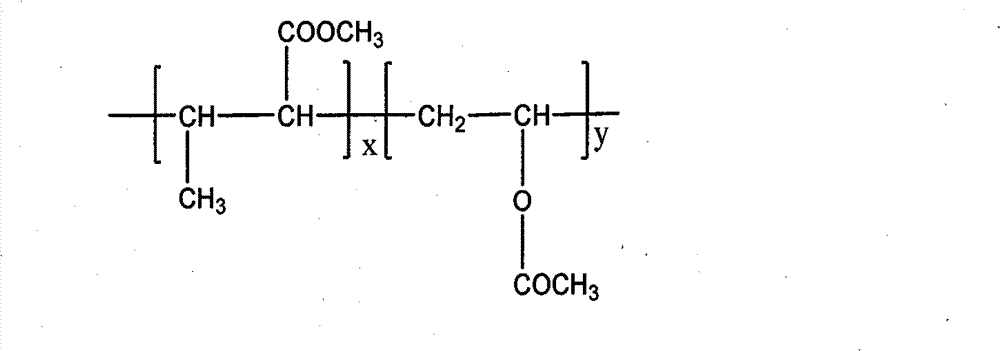

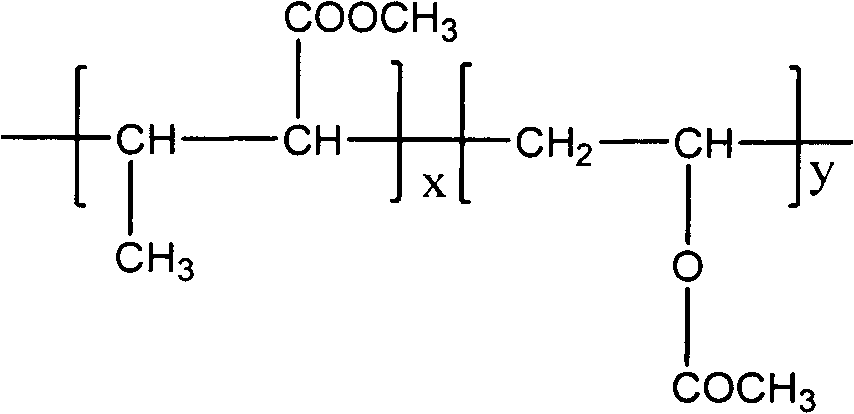

Image

Examples

Embodiment 1

[0041] This example is used to illustrate the corona-resistant composition provided by the present invention and its preparation method.

[0042] Weigh 20g of nano-alumina particles with an average particle size of 80nm, 0.6g of γ-aminopropyltriethoxysilane coupling agent, 0.2g of polyester-modified acrylate block copolymer dispersant, and 800mL of solvent N, N-dimethylacetamide, put into the double-layer glass reactor (RAT, Wuxi Shenke Instrument Factory), under the condition that the rotating speed is 1000r / min, stir for 1h to obtain the nano-alumina slurry, weigh 71.60g of 4,4'-diaminodiphenyl ether was added to the nano-alumina slurry, and after stirring and dissolving, 78.47g of pyromellitic dianhydride was weighed and added to the nano-alumina slurry. , reacted for 4 hours to obtain nano-alumina / polyamic acid composite slurry, filtered the composite slurry, degassed for 2 hours at 25 ° C, vacuum degree of 0.01 MPa, and then kept at 100 ° C for 1 hour. Keep at 200°C for ...

Embodiment 2

[0044] This example is used to illustrate the corona-resistant composition provided by the present invention and its preparation method.

[0045] Weigh 20g of nano-alumina particles with an average particle size of 100nm, 0.6g of γ-mercaptan aminopropyl trimethoxysilane coupling agent, 0.2g of polyester-modified acrylate block copolymer dispersant, and 800mL The solvent N,N-dimethylformamide was put into a double-layer glass reaction kettle (RAT, Wuxi Shenke Instrument Factory), and stirred for 1h under the condition of a rotating speed of 1400r / min to obtain a nano-alumina slurry, which was called Take 78.76g of 4,4'-diaminodiphenyl ether and add it to the slurry, stir and dissolve, weigh 86.32g of 4,4'-biphenyltetracarboxylic dianhydride, and add it to the nano-alumina slurry , at room temperature, react for 4 hours to obtain nano-alumina / polyamic acid composite slurry, filter the composite slurry, degas the vacuum at 30 ° C for 3 hours at a vacuum degree of 0.01 MPa, and th...

Embodiment 3

[0047] This example is used to illustrate the corona-resistant composition provided by the present invention and its preparation method.

[0048] Weigh 15g of nano-alumina particles with an average particle size of 50nm, 0.5g of γ-mercaptan aminopropyl trimethoxysilane coupling agent, 0.1g of polyester-modified acrylate block copolymer dispersant, and 600mL The solvent N,N-dimethylformamide was put into a double-layer glass reaction kettle (RAT, Wuxi Shenke Instrument Factory), and the rotation speed was 120r / min, and stirred for 2h to obtain a nano-alumina slurry, which was called Take 53.7g of 4,4'-diaminodiphenyl ether and add it to the slurry, stir and dissolve, weigh 58.85g of 3,3',4,4'-benzophenone tetracarboxylic dianhydride, add Into the nano-alumina slurry, react for 4 hours at 40°C to obtain a nano-alumina / polyamic acid composite slurry, filter the composite slurry, and vacuum degas at 25°C and a vacuum of 0.01 MPa for 2 hours Hours, then kept at 100°C for 1 hour, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com