Macromolecule polymer emulsion as well as preparation method thereof and waterproof coating prepared from emulsion

A high-molecular polymer and emulsion technology, applied in the field of coatings, can solve the problems of low tensile strength and elongation, high and low temperature flexibility, curing of waterproof materials, and poor high and low temperature characteristics, so as to achieve good water resistance and coating film elasticity Large, excellent weather resistance and the effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

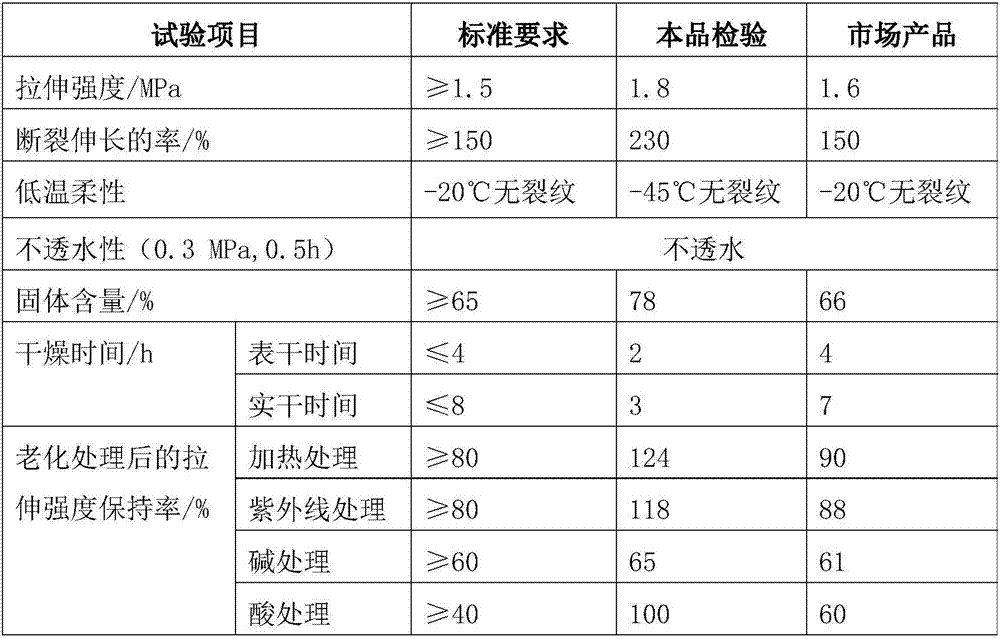

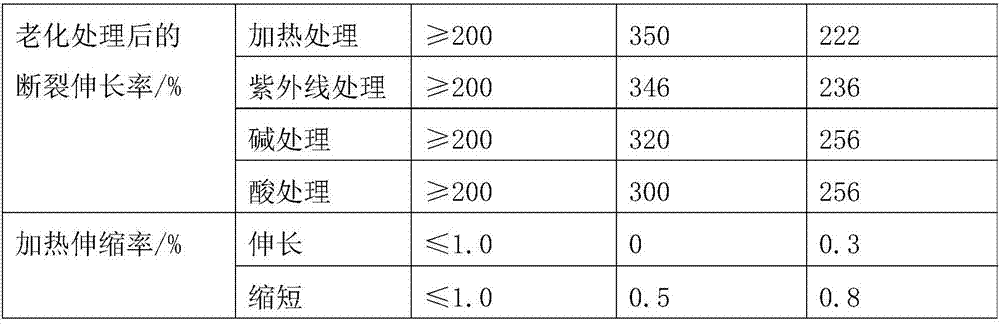

Examples

Embodiment 1

[0056] Embodiment 1: a kind of polymer emulsion, it comprises each component of following mass fraction: 0.1 part of chloroprene latex, 3 parts of butyl latex, 45 parts of ethyl acrylate latex, 15 parts of siloxane emulsion, ortho 4 parts of dibutyl phthalate, 0.045 parts of anionic surfactant, 2 parts of polyvinyl alcohol, 18 parts of polysiloxane, 19 parts of sodium hydroxide, and 0.2 parts of auxiliary agent; wherein, the auxiliary agent is a thickening suspending agent.

Embodiment 2

[0057] Embodiment 2: a kind of preparation method of polymer emulsion, comprises the following steps: (1) batching; (2) prepares the first emulsion; (3) prepares waterproofing agent; (4) prepares the second emulsion; (5) Preparation of auxiliary agent solution; (6) preparation of finished product; wherein,

[0058] (1) Ingredients

[0059] Weigh each component according to the following parts by mass: 0.1 part of neoprene latex, 3 parts of butyl latex, 45 parts of ethyl acrylate latex, 15 parts of silicone emulsion, 4 parts of dibutyl phthalate, anionic surfactant 0.045 parts of agent, 2 parts of polyvinyl alcohol, 18 parts of polysiloxane, 19 parts of sodium hydroxide, 0.2 part of auxiliary agent; wherein, the auxiliary agent is a thickening suspending agent;

[0060] (2) Preparation of the first emulsion

[0061] In the reaction kettle, add 0.1 parts of neoprene latex, 3 parts of butyl latex, 45 parts of ethyl acrylate latex, 15 parts of siloxane emulsion, 4 parts of dibut...

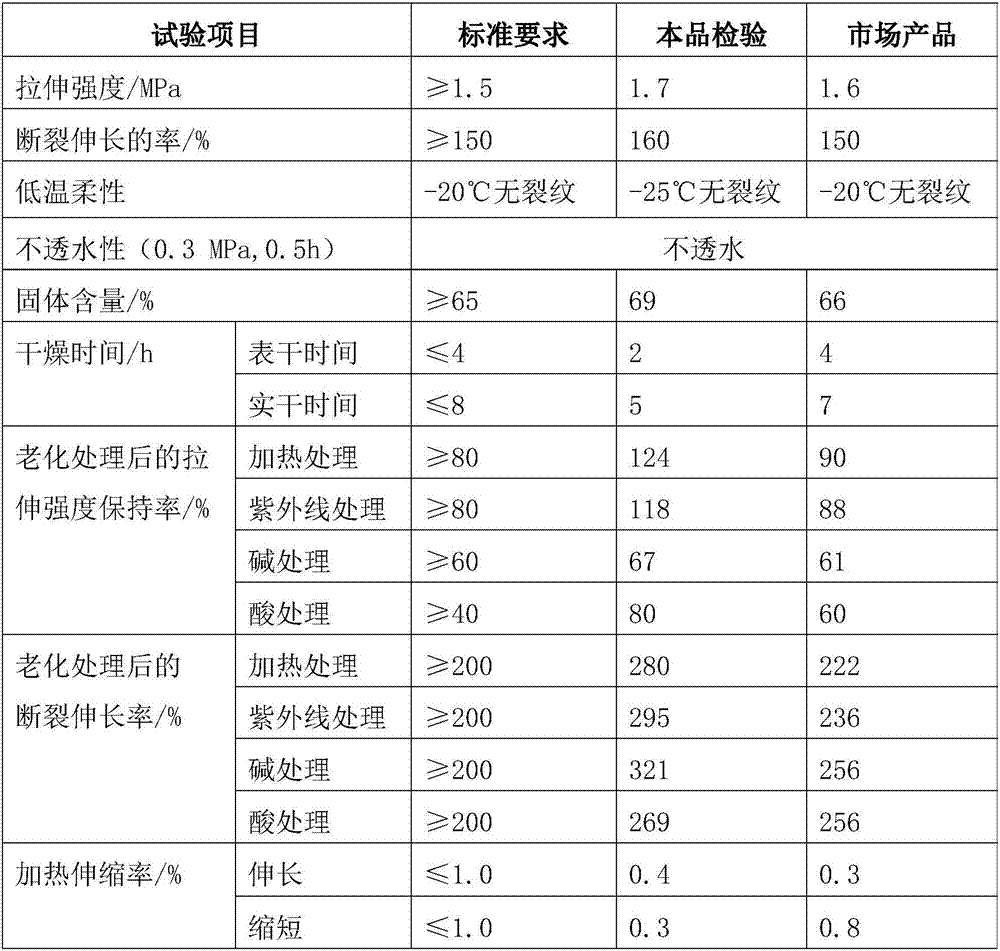

Embodiment 3

[0071] Embodiment 3: a kind of polymer latex, it comprises each component of following mass fraction: 1 part of chloroprene latex, 3.6 parts of butyl latex, 47 parts of ethyl acrylate latex, 16 parts of siloxane emulsion, ortho 5 parts of dibutyl phthalate, 2.5 parts of anionic surfactant, 2.7 parts of polyvinyl alcohol, 20 parts of polysiloxane, 20 parts of sodium hydroxide, and 0.6 parts of auxiliary agent; wherein, the auxiliary agent is a thickening suspending agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com