Waterborne polyurethane resin dispersion and use thereof

A water-based polyurethane and polyurethane resin technology, applied in polyurea/polyurethane coatings, coatings, latex paints, etc., can solve the problems of insufficient solvent resistance and water resistance of the coating film, which cannot be said to be sufficient, and achieve high water resistance , Excellent impact resistance and high fracture energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

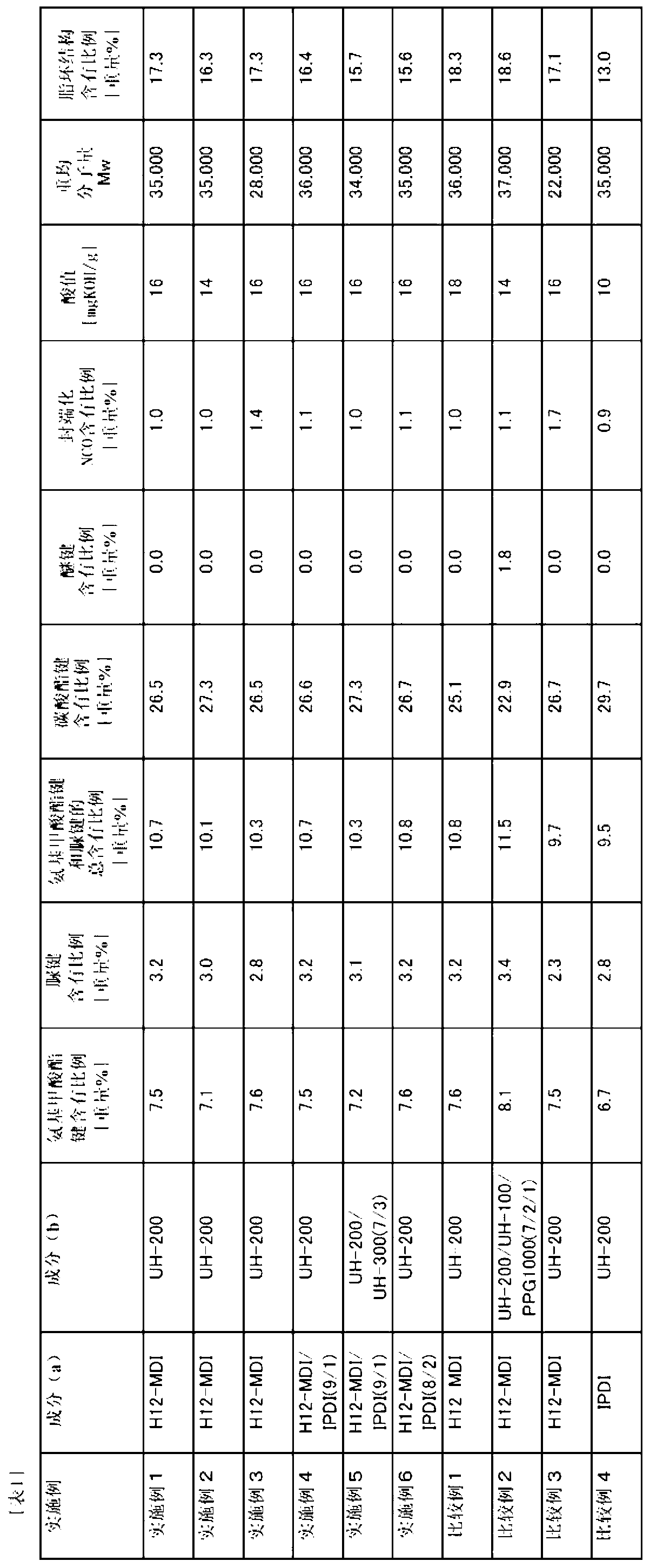

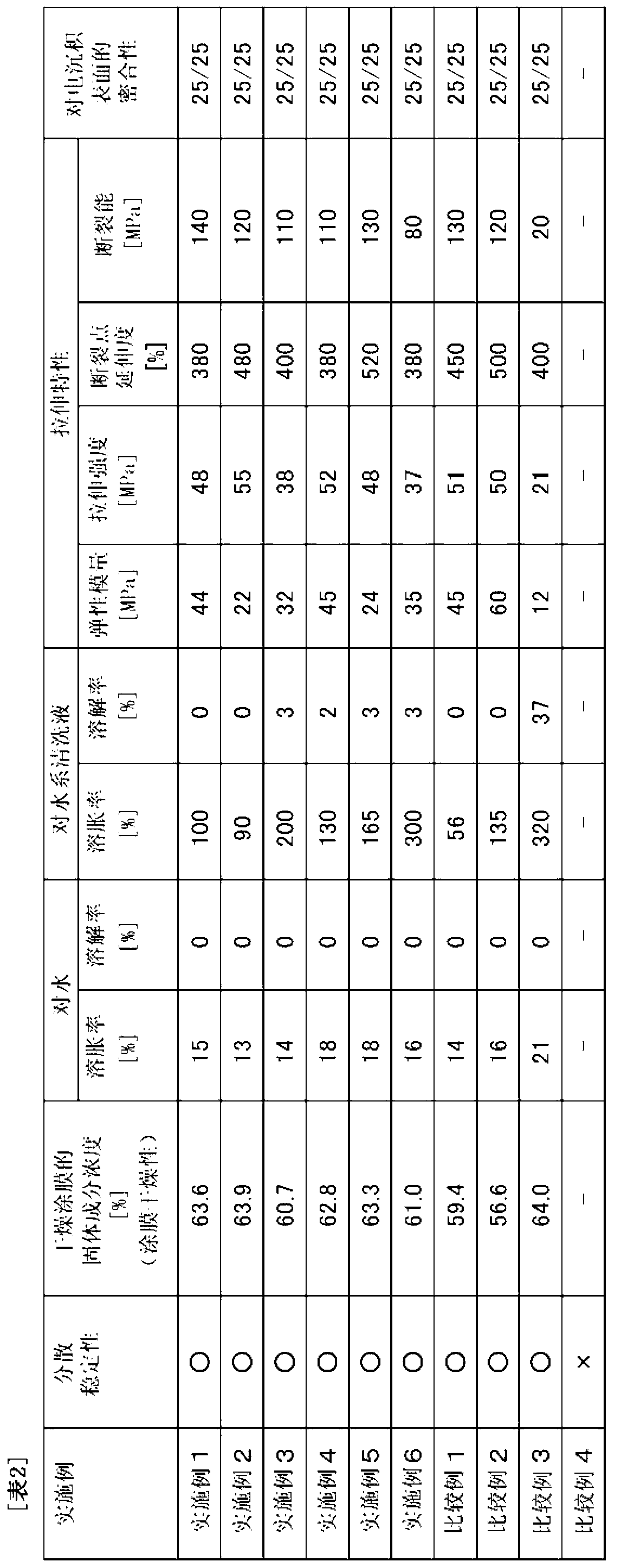

Embodiment 1

[0136] [Manufacture of water-based polyurethane resin dispersion (1)]

[0137] Add ETERNACOLL UH-200 (registered trademark; polycarbonate diol produced by Ube Industries; number average molecular weight 1986; hydroxyl value 56.4mgKOH / g; make 310 g of polycarbonate diol obtained by reacting 1,6-hexanediol and dimethyl carbonate), 18.3 g of 2,2-dimethylolpropionic acid (DMPA), and 154 g of N-methylpyrrolidone (NMP). Thereafter, it was heated and stirred at 60° C., and it was confirmed that DMPA was dissolved. 133 g of 4,4'-dicyclohexylmethane diisocyanate (hydrogenated MDI) and 0.38 g of dibutyltin dilaurate (catalyst) were added, heated to 90° C., and urethanization reaction was performed over 5 hours. Thereafter, 11.2 g of 3,5-dimethylpyrazole (DMPZ) was injected, and stirring was continued at the same temperature for 1.5 hours to obtain a polyurethane prepolymer. The free isocyanate group content ratio at the end of the urethanization reaction was 1.79% by weight. The reac...

Embodiment 2

[0141] [Manufacture of water-based polyurethane resin dispersion (2)]

[0142] Add ETERNACOLL UH-200 (registered trademark; polycarbonate diol produced by Ube Industries; number average molecular weight 2025; hydroxyl value 55.4mgKOH / g; make 1,6-hexane 325 g of polycarbonate diol obtained by reacting diol and dimethyl carbonate), 16.3 g of 2,2-dimethylolpropionic acid (DMPA), and 155 g of N-methylpyrrolidone (NMP). Thereafter, it was heated and stirred at 60° C., and it was confirmed that DMPA was dissolved. 127 g of 4,4'-dicyclohexylmethane diisocyanate (hydrogenated MDI) and 0.38 g of dibutyltin dilaurate (catalyst) were added, heated to 90°C, and urethanization reaction was performed over 5 hours. Thereafter, 10.4 g of 3,5-dimethylpyrazole (DMPZ) was injected, and stirring was continued at the same temperature for 1.5 hours to obtain a polyurethane prepolymer. The free isocyanate group content ratio at the end of the urethanization reaction was 1.70% by weight. The reactio...

Embodiment 3

[0146] [Manufacture of water-based polyurethane resin dispersion (3)]

[0147] Add ETERNACOLL UH-200 (registered trademark; polycarbonate diol manufactured by Ube Industries; number average molecular weight 1968; hydroxyl value 57.0mgKOH / g; make 1,6-hexane 311 g of polycarbonate diol obtained by reacting diol and dimethyl carbonate), 18.6 g of 2,2-dimethylolpropionic acid (DMPA), and 157 g of N-methylpyrrolidone (NMP). Thereafter, it was heated and stirred at 60° C., and it was confirmed that DMPA was dissolved. 138 g of 4,4'-dicyclohexylmethane diisocyanate (hydrogenated MDI) and 0.38 g of dibutyltin dilaurate (catalyst) were added, heated to 90°C, and urethanization reaction was performed over 5 hours. Thereafter, 11.1 g of 3,5-dimethylpyrazole (DMPZ) was injected, and stirring was continued at the same temperature for 1.5 hours to obtain a polyurethane prepolymer. The free isocyanate group content ratio at the end of the urethanization reaction was 1.49% by weight. The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com