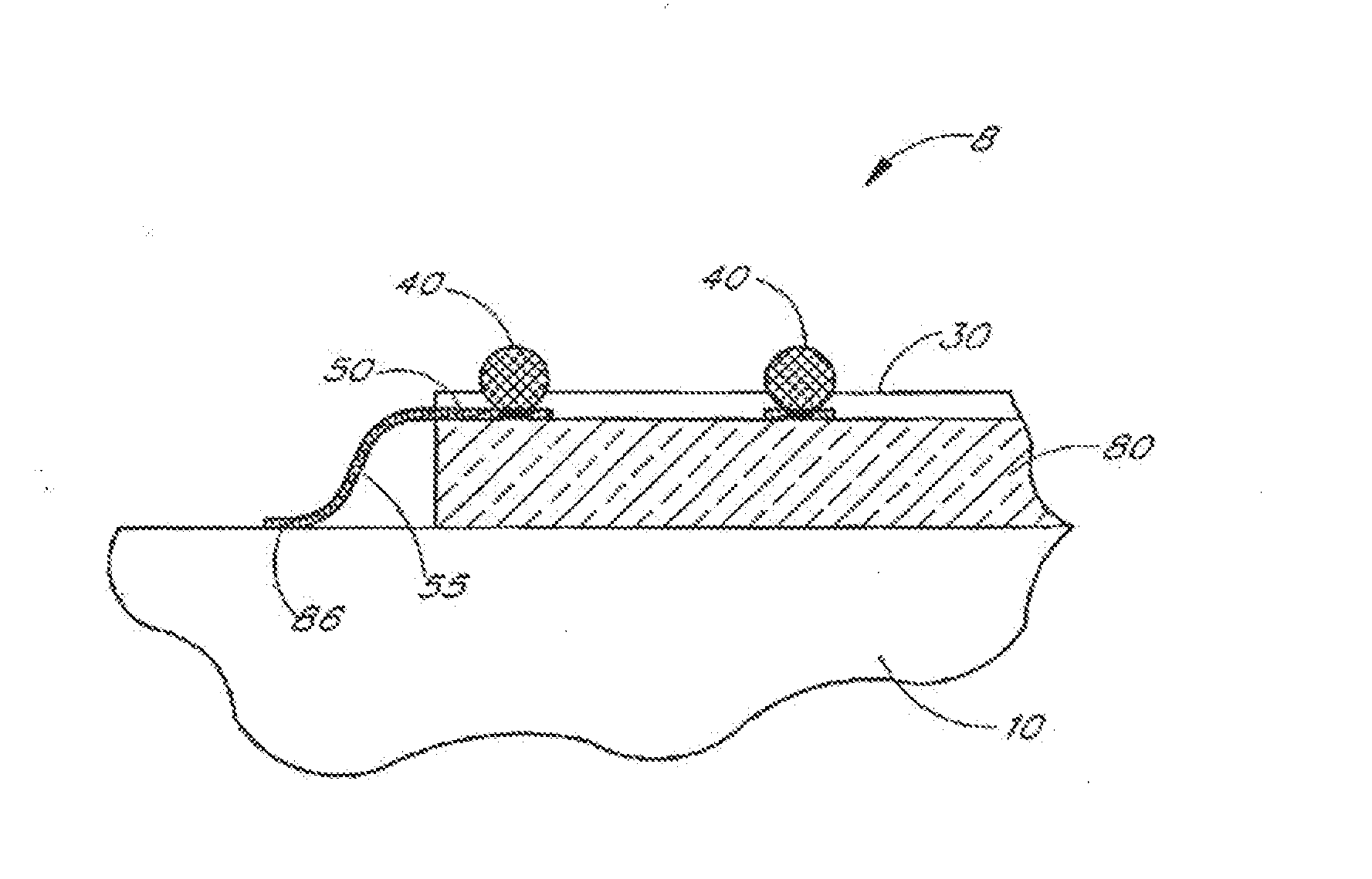

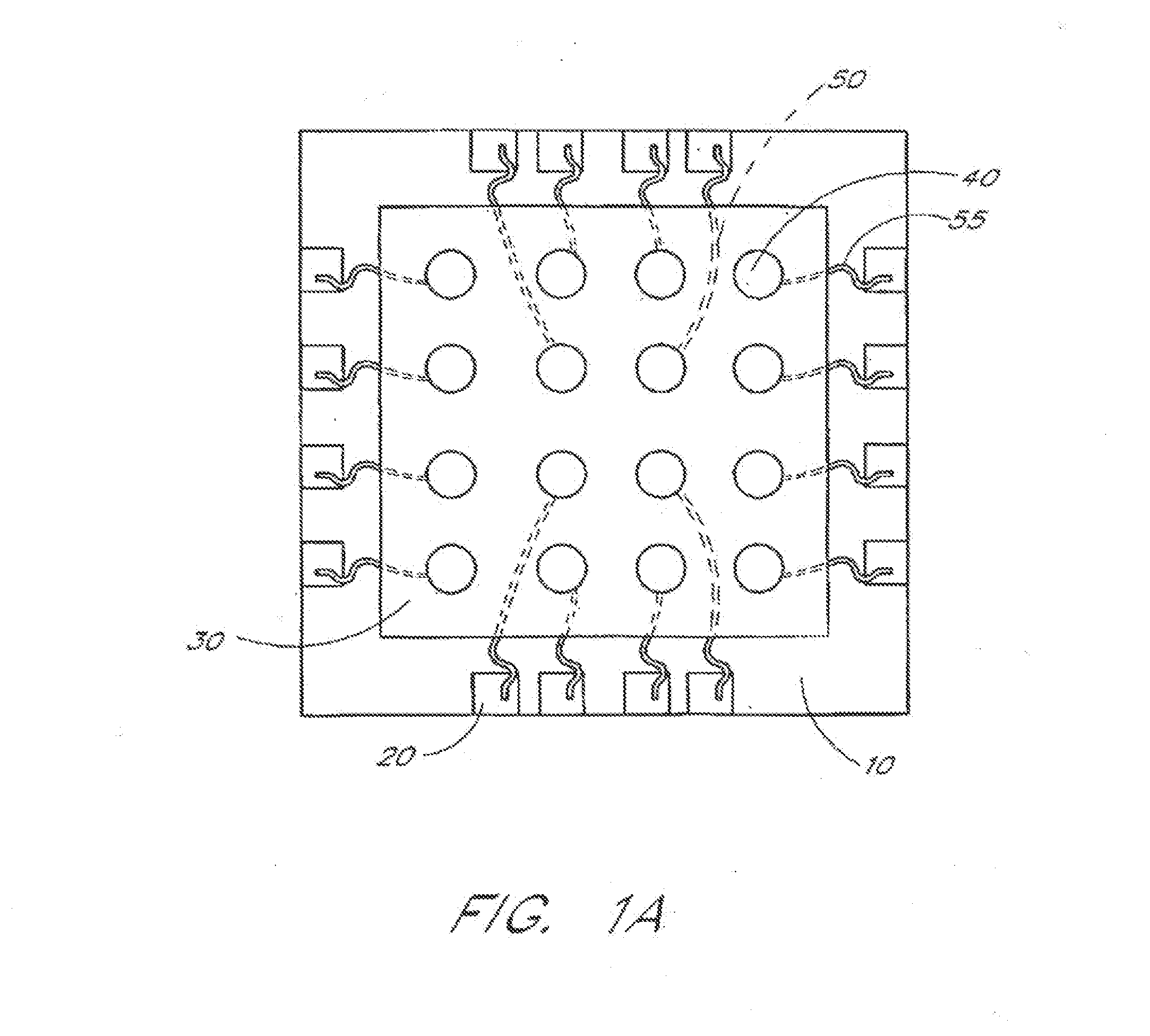

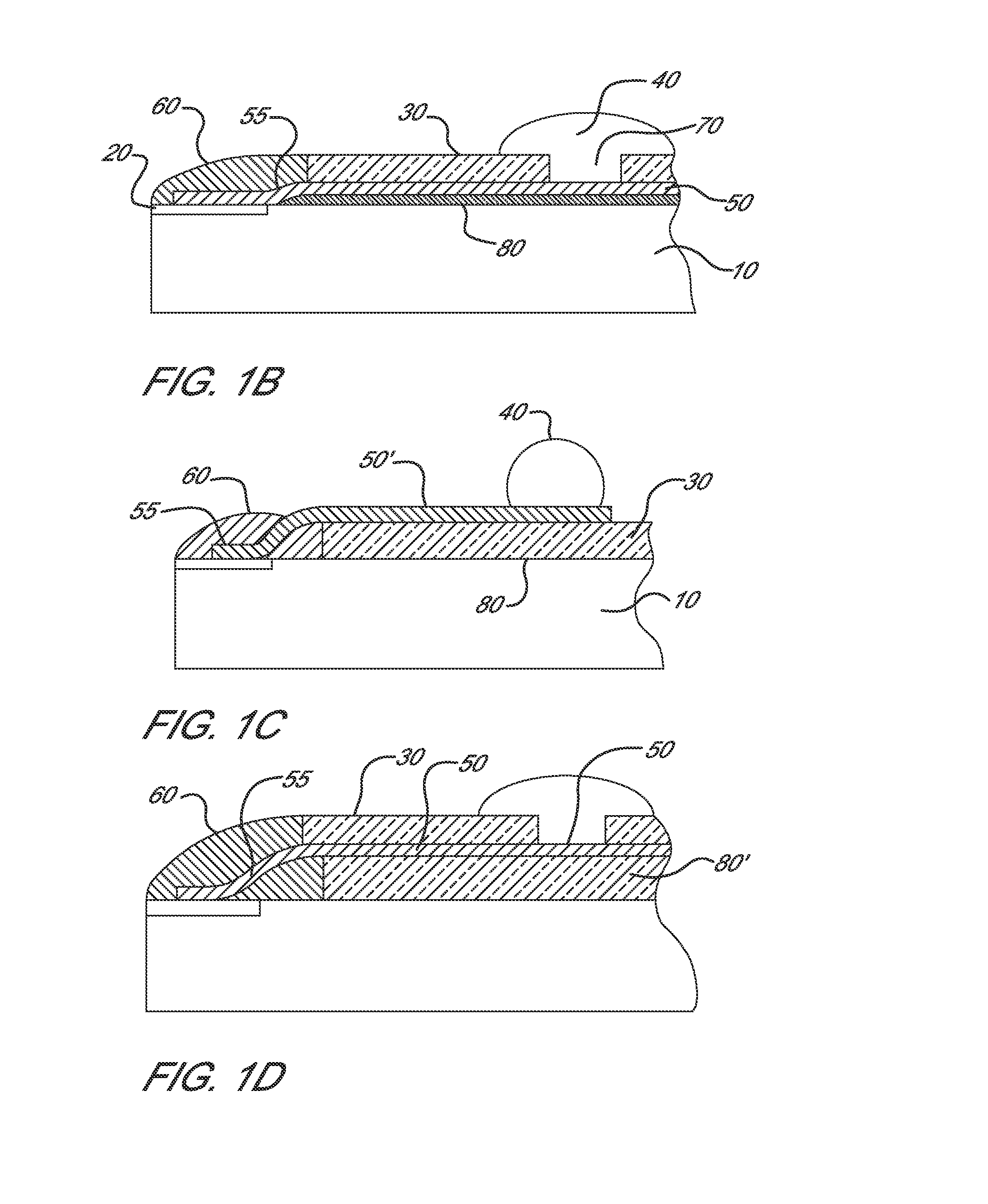

Interposer films useful in semiconductor packaging applications, and methods relating thereto

a technology of interposer film and semiconductor packaging, which is applied in the direction of transportation and packaging, synthetic resin layered products, coatings, etc., can solve the problems of interposer film exhibiting dimensional distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

15 vol % (34.3 wt %) Acicular TiO2 in PMDA / / ODA

[0118]25.0 grams of acicular TiO2 (FTL-110, Ishihara Corporation, USA) was combined with 141.11 grams of anhydrous DMAC. This slurry was mixed at high shear for approximately 10 to 15 minutes using Silverson Model L4RT high-shear mixer (Silverson Machines, LTD, Chesham Baucks, England) equipped with a square-hole, high-shear screen (with a blade speed of approximately 4000 rpm).

[0119]In a round bottom flask, 74.1 grams of the slurry containing acicular TiO2 was mixed with 116.94 grams of PMDA / / ODA prepolymer (20 wt % solution in anhydrous DMAC), and the resulting mixture was stirred for approximately 24 hours. During this operation, a gentle nitrogen gas purge was used in the round bottom flask.

[0120]After stirring for approximately 24 hours, this material was filtered through 45 micron filter media (Millipore, 45 micron polypropylene screen, PP4504700).

[0121]In a separate container, a 6 wt % solution of pyromellitic anhydride (PMDA) wa...

example 2

10 vol % (24.70 wt %) Acicular TiO2 (FTL-110) in PMDA / / ODA

[0135]The same procedure as described in Example 1 was followed, with the following exceptions. 54.24 grams of the slurry containing acicular TiO2 (FTL-110, 15 wt % in DMAC) was mixed with 136.15 grams of PMDA / / ODA prepolymer (20 wt % in DMAC).

[0136]The material was finished with the PMDA solution to a viscosity of 899 poise.

[0137]CTE, E′ and % elongation at break were measured as in Example 1.

[0138]Results are shown in Table 1.

example 3

20 vol % (42.5 wt %) Acicular TiO2 (FTL-110) in PMDA / / ODA

[0139]The same procedure as described in Example 1 was followed, with the following exceptions. 57.7 grams of the slurry containing acicular TiO2 (FTL-110, 15 wt % in DMAC, high shear mixed) was combined with 63.3 grams of PMDA / / ODA prepolymer (20.6 wt % in DMAC).

[0140]The material was finished with the PMDA solution to a viscosity of 1380 poise.

[0141]CTE, E′ and % elongation at break were measured as in Example 1.

[0142]Results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume percent | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com