Aromatic diamine with phthalonitrile pendant group, preparation method thereof and polyimides or polyamide prepared therefrom

An aromatic diamine and phthalonitrile technology, which is applied in the dehydration preparation of carboxylic acid amides, organic chemistry and other directions, can solve the problems of large brittleness of polymers, poor film-forming properties, and reduced rigidity of polyimide molecular chains, etc. Achieve the effect of broadening the scope of application, excellent mechanical properties and solvent resistance, and expanding the scope of application

Inactive Publication Date: 2008-11-19

SICHUAN UNIV

View PDF0 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(1) Since the phthalonitrile unit is at the end of the polymer chain, its reactivity is limited by the molecular weight of the polymer. If the molecular weight is too large, the phthalonitrile reactivity decreases, making it difficult to form an effective crosslink (U.S.Pat. No.5,132,396), the molecular weight is too small, and the cross-linking density of the polymer is too large, which will make the polymer more brittle

(2) The molecular weight of the existing phthalonitrile-terminated polyimides is generally within the range of 2000g / mol, so its film-forming property is poor, which limits its application in the field of film materials and fibers. application

Because traditional aromatic polyamides are usually infusible and insoluble, it is difficult to process, so people have studied many modification methods to improve the processability of polyamides.

These means of modification mainly include the introduction of side groups (Meyer.M.R.Macromolecules, 24,642) on the main chain of polyamides. Although these means can significantly improve the organic solubility and processability of polyamides, due to the The reduction of rigidity, thus sacrificing the excellent thermal properties, mechanical properties and solvent resistance of polyamides, limits the application range of polyamides

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

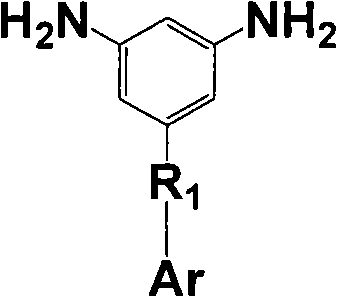

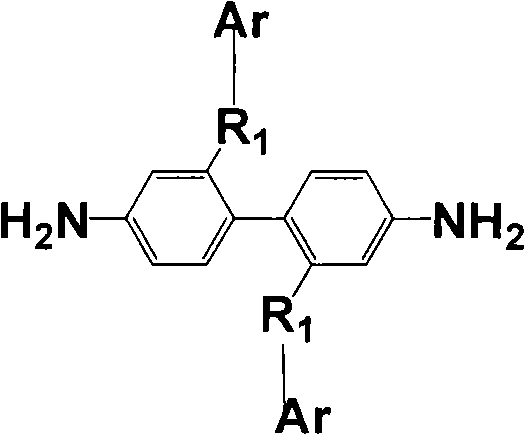

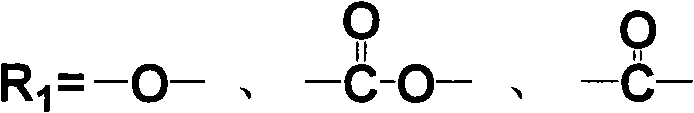

The invention discloses an aromatic diamine containing o-phthalonitrile side group. The structure formula of the aromatic diamine is shown as the right formula. The invention also discloses a method for preparing the aromatic diamine and polyimide and daiamid which are prepared by taking the aromatic diamine containing the o-phthalonitrile side group as one of raw materials. The o-phthalonitrile side group in the aromatic diamine is positioned on the side chain, thereby adjusting the degree of crosslinking with adjusting the polymer molecular weight and widening the application of the polyimide and the daiamid in a thick-wall composite material or a composite material element with a complicated shape and the fields of membrane material and fiber.

Description

technical field The invention belongs to the technical field of aromatic diamines and their preparation methods and polyimides or polyamides, in particular to aromatic diamines containing phthalonitrile side groups and their preparation methods and their preparation methods by containing phthalonitrile Aromatic diamines are used as monomers to prepare polyimides or polyamides containing phthalonitrile side groups. Background technique Polyimide (PI) is a class of high-performance polymers containing imide rings in the main chain. Due to its excellent thermal stability, mechanical properties, chemical inertness, dielectric properties and radiation resistance, it has long been used as a film, Commodity forms such as coatings, fibers, plastics, adhesives and resin-based composites are widely used in high-tech fields such as aerospace and electronics industries. Polyimide is prepared by polycondensation reaction using aromatic dianhydride and diamine, and its synthesis process ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C255/54C07C255/58C07C255/57C07C253/20C08G73/10C08G69/32

Inventor 杨刚曾科周鸿飞洪海兵周韶鸿刘韬缪培凯

Owner SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com