Preparation method of high-hydrophilicity polyamide 6 and high-hydrophilicity polyamide 6 fiber

A polyamide and hydrophilic technology, which is applied in the field of preparation of functional polymers, can solve the problems of high price of irradiation γ-ray sources, difficulty in industrial production, difficulty in ensuring uniformity, etc., to achieve suitable industrial production, easy operation and realization , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

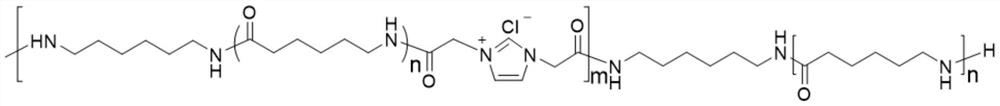

[0032] A kind of preparation method of highly hydrophilic polyamide 6 provided by the invention comprises the following steps:

[0033] S1. Preparation of dicarboxyimidazole quaternary ammonium salt

[0034] N-(trimethylsilyl) imidazole is reacted with ethyl chloroacetate to obtain imidazole quaternary ammonium salt substituted by ethyl diacetate; then ethyl acetate is hydrolyzed to obtain dicarboxy imidazole quaternary ammonium salt; wherein, the hydrolysis is acidic Conditional hydrolysis, the hydrolysis reaction time is 6-15h. The acid used for hydrolysis is preferably hydrochloric acid.

[0035] The reaction temperature of N-(trimethylsilyl)imidazole and ethyl chloroacetate is 50-80°C, the time is 12-30h, and the reaction atmosphere is nitrogen atmosphere.

[0036]

[0037] S2. Preparation of caprolactam prepolymer

[0038] Ring-opening polymerization of caprolactam, and then adding hexamethylenediamine to obtain a caprolactam prepolymer with amino groups at both end...

Embodiment 1-6

[0047] A preparation method for highly hydrophilic polyamide 6, comprising the following steps:

[0048] 1. Synthesis of dicarboxyimidazole quaternary ammonium salt

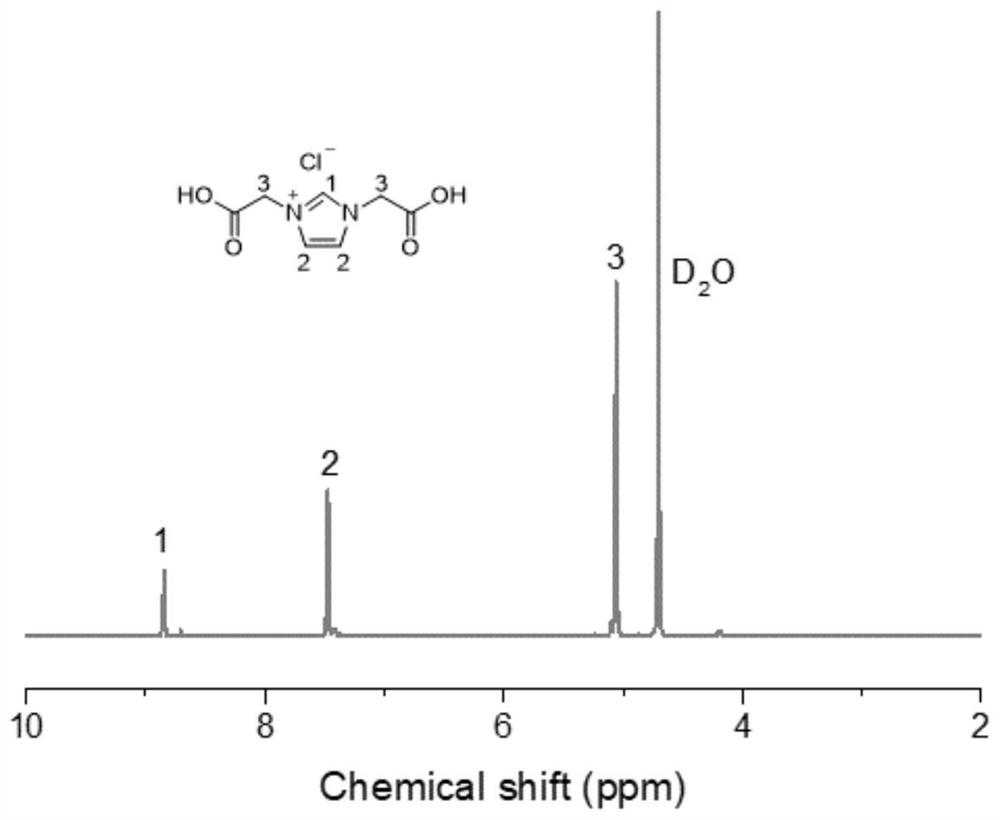

[0049] Under a nitrogen atmosphere, ethyl chloroacetate was added to N-(trimethylsilyl)imidazole, and reacted at 60° C. for 24 hours to obtain a solid crude product. Afterwards, the crude product was cooled to room temperature, dissolved in a small amount of water, and extracted three times with ethyl acetate to remove unreacted monomers. Then, an appropriate amount of hydrochloric acid aqueous solution was added to the water phase for hydrolysis, and stirred at room temperature for 12 hours. Hydrogen chloride and solvent were removed by rotary evaporation to obtain a solid product with a yield of 93%.

[0050] see figure 1 Shown, can explain the successful synthesis of dicarboxyimidazole quaternary ammonium salt.

[0051] 2. Synthesis of Caprolactam Prepolymer

[0052] Set up the reaction device, first pass...

Embodiment 7-8

[0061] A method for preparing highly hydrophilic polyamide 6. Compared with Example 3, the difference is that the amount of hexamethylenediamine added in Step 2 is changed, and the others are roughly the same as Example 3, and will not be repeated here.

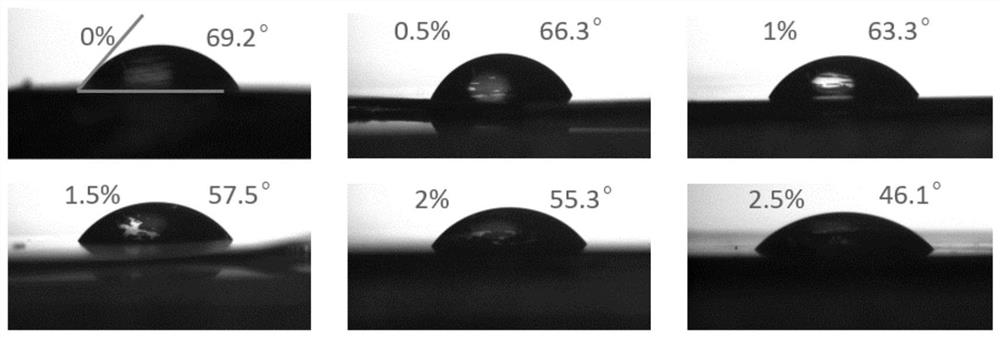

[0062] Preparation conditions and performance test results of table 2 embodiment 3 and embodiment 7-8

[0063]

[0064] It can be seen from Table 2 that with the increase of the addition of hexamethylenediamine, the water contact angle and fiber moisture regain of the hydrophilic polyamide 6 do not change much, indicating that the addition of hexamethylenediamine has little effect on the hydrophilicity of the fiber ; But too much addition of hexamethylenediamine increases the number of short-chain molecular weights in polyamide 6, resulting in a decrease in breaking strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com