A charged polyamide composite nanofiltration membrane and its preparation method

A composite nanofiltration membrane and polyamide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as loss of inorganic nanomaterials, influence on membrane structure and performance, and weak interaction force, etc., to achieve Promote dispersion, inhibit agglomeration behavior, increase the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

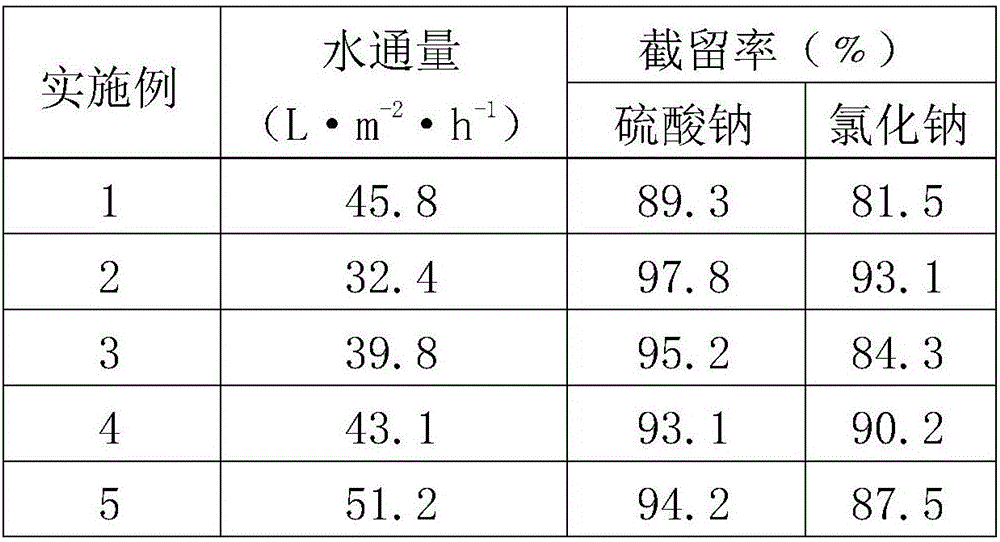

Examples

Embodiment 1

[0023] By reversible addition-fragmentation chain transfer (RAFT) polymerization, polymethacrylic acid was grafted on silica nanoparticles with a diameter of 30 nm to obtain polymethacrylic acid-modified silica nanoparticles, polymethacrylic acid The number-average molecular weight is 6,000 g / mol; 0.1 g of polymethacrylic acid-modified silica nanoparticles and 0.5 g of ethylenediamine are dispersed in 99.4 g of water to prepare 100 g of polymethacrylic acid-modified silica The aqueous phase ethylenediamine solution of nanoparticles, and adjust the pH value of the aqueous phase ethylenediamine solution to 7; immerse the polyethersulfone ultrafiltration membrane in the aqueous phase ethylenediamine solution after adjusting the pH value, and take out the membrane after 15 minutes , wipe off the excess water phase solution on the surface of the membrane; then immerse in n-hexane solution containing 10% trimesoyl chloride by mass percentage, take it out after 0.5 minutes, rinse with...

Embodiment 2

[0025] By reversible addition-fragmentation chain transfer (RAFT) polymerization, polyacrylic acid was grafted on silica nanoparticles with a diameter of 180 nm to obtain polyacrylic acid-modified silica nanoparticles, and the number average molecular weight of polyacrylic acid was 400,000 g / mole; 10g polyacrylic acid-modified silica nanoparticles and 10g m-phenylenediamine are dispersed in 80g water to prepare 100g aqueous phase m-phenylenediamine solution containing polyacrylic acid-modified silica nanoparticles, and adjust the water phase The pH value of the phenylenediamine solution is up to 12; immerse the polysulfone ultrafiltration membrane in the aqueous m-phenylenediamine solution after adjusting the pH value, take out the membrane after 0.5 minutes, and wipe off the excess aqueous organic phase solution on the surface of the membrane; then immerse The modified pair containing cyclohexane with a mass percentage of 0.5% isophthaloyl chloride, I neglected to put it in t...

Embodiment 3

[0027] By atom transfer radical polymerization (ATRP), polystyrene sulfonic acid was grafted on silica nanoparticles with a diameter of 90 nm to obtain polystyrene sulfonic acid-modified silica nanoparticles, polystyrene sulfonic acid The number-average molecular weight is 30,000 g / mol; 5 g of polystyrene sulfonic acid-modified silica nanoparticles and 2 g of p-phenylenediamine are dispersed in 93 g of water to prepare 100 g of polystyrene sulfonic acid-modified silica nanoparticles The water relative phenylenediamine solution, and adjust the pH value of the water relative phenylenediamine solution to 9; immerse the polyacrylonitrile ultrafiltration membrane in the water relative phenylenediamine solution after adjusting the pH value for 5 minutes, take out the membrane, wipe Remove excess water phase solution on the surface of the membrane; then immerse in a cyclohexane solution containing 4% terephthaloyl chloride by mass, take it out after 5 minutes, rinse with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com