Polyphenylene ether resin composite material and its preparation method and application

A technology of polyphenylene ether resin and composite material, which is applied in the field of polyphenylene ether resin composite material and its preparation, can solve the problems of stress cracking and poor toughness of polyphenylene ether resin, and achieves stable performance, low cost and easily controllable conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

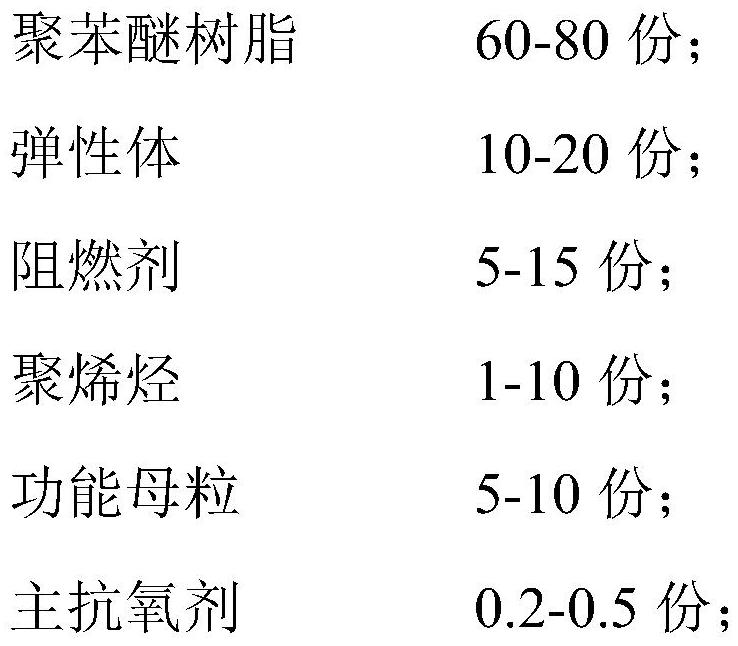

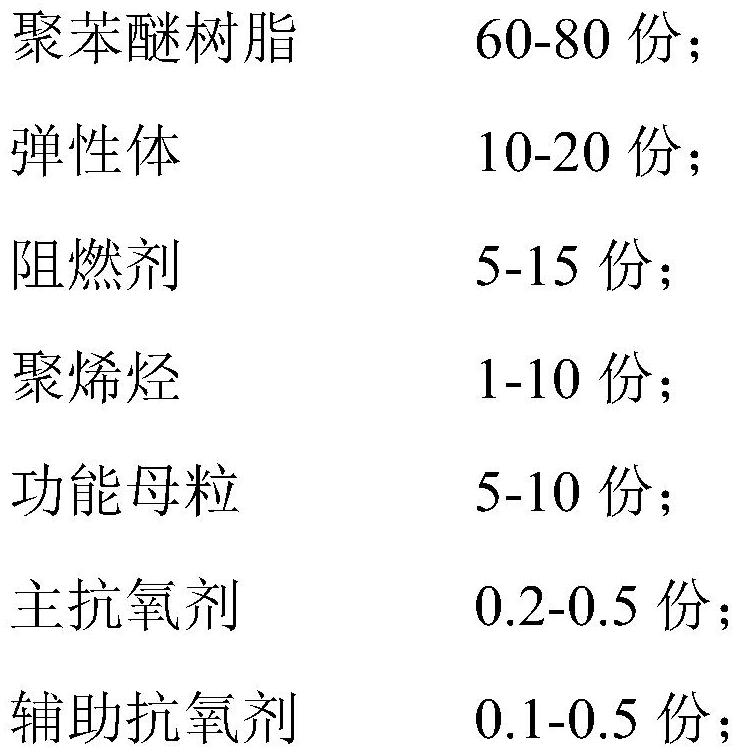

[0054]Correspondingly, an embodiment of the present invention provides a method for preparing a polyphenylene ether resin composite material, the polyphenylene ether resin composite material includes the following components by weight:

[0055]

[0056]Wherein, based on the total weight of the functional masterbatch as 100%, the functional masterbatch includes the following components in the following weight percentages:

[0057]Resin base material 60-79%;

[0058]20-39% of fumed nano-silica with branched structure;

[0059]Coupling agent 1-3%;

[0060]And the coupling agent is coated on the surface of the fumed nano silica having a branched structure;

[0061]The preparation method of the polyphenylene ether resin composite material includes the following steps:

[0062]S01. Weigh the components according to the formula of the polyphenylene ether resin composite;

[0063]S02. Mixing the polyphenylene ether resin and the elastomer to obtain a first mixture;

[0064]S03. Mixing the polyolefin, flame retardant, fu...

Embodiment 1

[0088]A polyphenylene ether resin composite material whose formula composition is shown in Table 1, specifically: 70 parts polyphenylene ether resin (PPO), 5 parts elastomer, 8 parts flame retardant, 1 part polyolefin, 15.7 parts functional masterbatch , 0.2 part of primary antioxidant and 0.1 part of auxiliary antioxidant; wherein, based on the total weight of the functional masterbatch as 100%, the functional masterbatch includes the following components in the following weight percentages: polyphenylene 70% ether resin resin base, 28% fumed silica with branched structure, 2% coupling agent.

[0089]The preparation method of the polyphenylene ether resin composite material includes: 70 parts of polyphenylene ether resin (PPO) and 5 parts of elastomer are added from the mouth of the first loss-in-weight feeder, 8 parts of flame retardant, 1 part of polyolefin, and 15.7 parts Functional masterbatch, 0.2 part of main antioxidant and 0.1 part of auxiliary antioxidant are added from the m...

Embodiment 2

[0091]A polyphenylene ether resin composite material whose formula composition is shown in Table 1, specifically: 70 parts polyphenylene ether resin (PPO), 10 parts elastomer, 8 parts flame retardant, 1 part polyolefin, 10.7 parts functional masterbatch , 0.2 part of primary antioxidant and 0.1 part of auxiliary antioxidant; wherein, based on the total weight of the functional masterbatch as 100%, the functional masterbatch includes the following components in the following weight percentages: polyphenylene 68% ether resin resin base, 30% fumed silica with branched structure, 2% coupling agent.

[0092]The preparation method of the polyphenylene ether resin composite material includes: 70 parts of polyphenylene ether resin (PPO) and 10 parts of elastomer are added from the mouth of the first loss-in-weight feeder, 8 parts of flame retardant, 1 part of polyolefin, and 10.7 parts Functional masterbatch, 0.2 part of main antioxidant and 0.1 part of auxiliary antioxidant are added from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com