A kind of preparation method of organic-inorganic hybrid microporous separation membrane

A separation membrane and inorganic technology, applied in the field of membrane separation, can solve the problems of hybrid membrane structure and performance, easy loss of inorganic nanoparticles, weak interaction, etc., to facilitate large-scale development and production, inhibit agglomeration behavior, increase the effect of the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

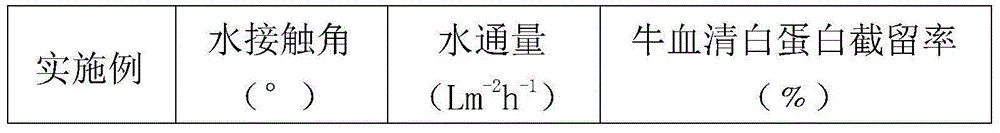

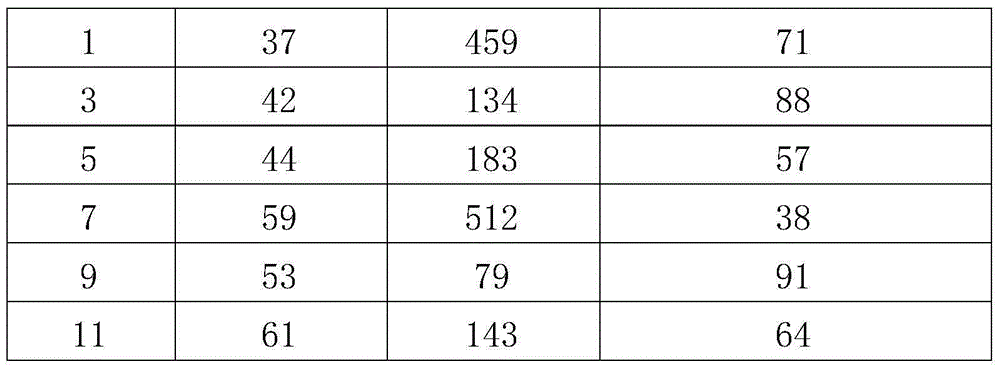

Examples

Embodiment 1

[0022] 60 g of poly(dimethylaminoethyl methacrylate) was grafted on the surface of 40 g of silica nanoparticles with a diameter of 100 nm by reversible addition-fragmentation chain transfer polymerization (RAFT), and centrifuged 10 times to obtain purified poly(dimethylaminoethyl methacrylate). (Dimethylaminoethyl methacrylate)-graft-silicon dioxide organic-inorganic hybrid nanoparticles, the weight-average molecular weight of the graft polymer is 600,000 grams / mole; 0.5g poly(dimethylaminomethacrylate) Ethyl ester)-graft-silica organic-inorganic hybrid nanoparticles are dispersed in the acetone solution of 99.5g 5-bromovaleric acid (the mass percent concentration of 5-bromovaleric acid in the acetone solution of 5-bromovaleric acid is 10% ), stirred at 10°C for 24 hours to achieve quaternization of poly(dimethylaminoethyl methacrylate), centrifuged 10 times to obtain purified quaternized organic-inorganic hybrid nanoparticles; 10 g of organic -Inorganic hybrid nanoparticles, ...

Embodiment 2

[0025]5 g of poly(diethylaminoethyl methacrylate) was grafted on the surface of 95 g of silica nanoparticles with a diameter of 30 nm by reversible addition-fragmentation chain transfer polymerization (RAFT), and centrifuged three times to obtain purified Poly(diethylaminoethyl methacrylate)-graft-silica organic-inorganic hybrid nanoparticles, the weight-average molecular weight of the graft polymer is 2,000 g / mol; 10g poly(diethyl methacrylate Aminoethyl ester)-graft-silica organic-inorganic hybrid nanoparticles are dispersed in an aqueous solution of 90g 3-bromopropionic acid (the mass percent concentration of 3-bromopropionic acid in the aqueous solution of 3-bromopropionic acid is 1%) , stirred at 80°C for 0.5 hours, and centrifuged three times to obtain purified quaternized organic-inorganic hybrid nanoparticles; 0.5g quaternized organic-inorganic hybrid nanoparticles, 85g N,N'-dimethyl Mix acetamide, 12g polyvinylidene fluoride, and 2.5g porogen (the mass ratio of polyet...

Embodiment 3

[0027] 45 g of poly(diethylaminoethyl acrylate) was grafted on the surface of 55 g of silica nanoparticles with a diameter of 50 nm by reversible addition-fragmentation chain transfer polymerization (RAFT), and centrifuged six times to obtain purified poly( Diethylaminoethyl methacrylate)-graft-silicon dioxide organic-inorganic hybrid nanoparticles, the weight average molecular weight of the graft polymer is 400,000 g / mol; 5g poly(diethylaminoethyl methacrylate )-graft-silica organic-inorganic hybrid nanoparticles are dispersed in the aqueous solution of 95g 1,3-propane sultone (the mass of 1,3-propanesulfonic acid in the aqueous solution of 1,3-propane sultone The percentage concentration is 2%) and stirred at 40°C for 8 hours to realize the quaternization of poly(diethylaminoethyl acrylate), and centrifuged 5 times to obtain purified quaternized organic-inorganic hybrid nanoparticles; Quaternized organic-inorganic hybrid nanoparticles, 79.5g N, N'-dimethylacetamide, 18g poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com