Polyester-imide wire coating enamel and preparation method thereof

A technology of enameled wire paint and polyesterimide, applied in the field of enameled wire paint, can solve the problem that polyesterimide enameled wire paint does not have refrigerant resistance and other problems, and achieves good refrigerant resistance, cost saving and high imine content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

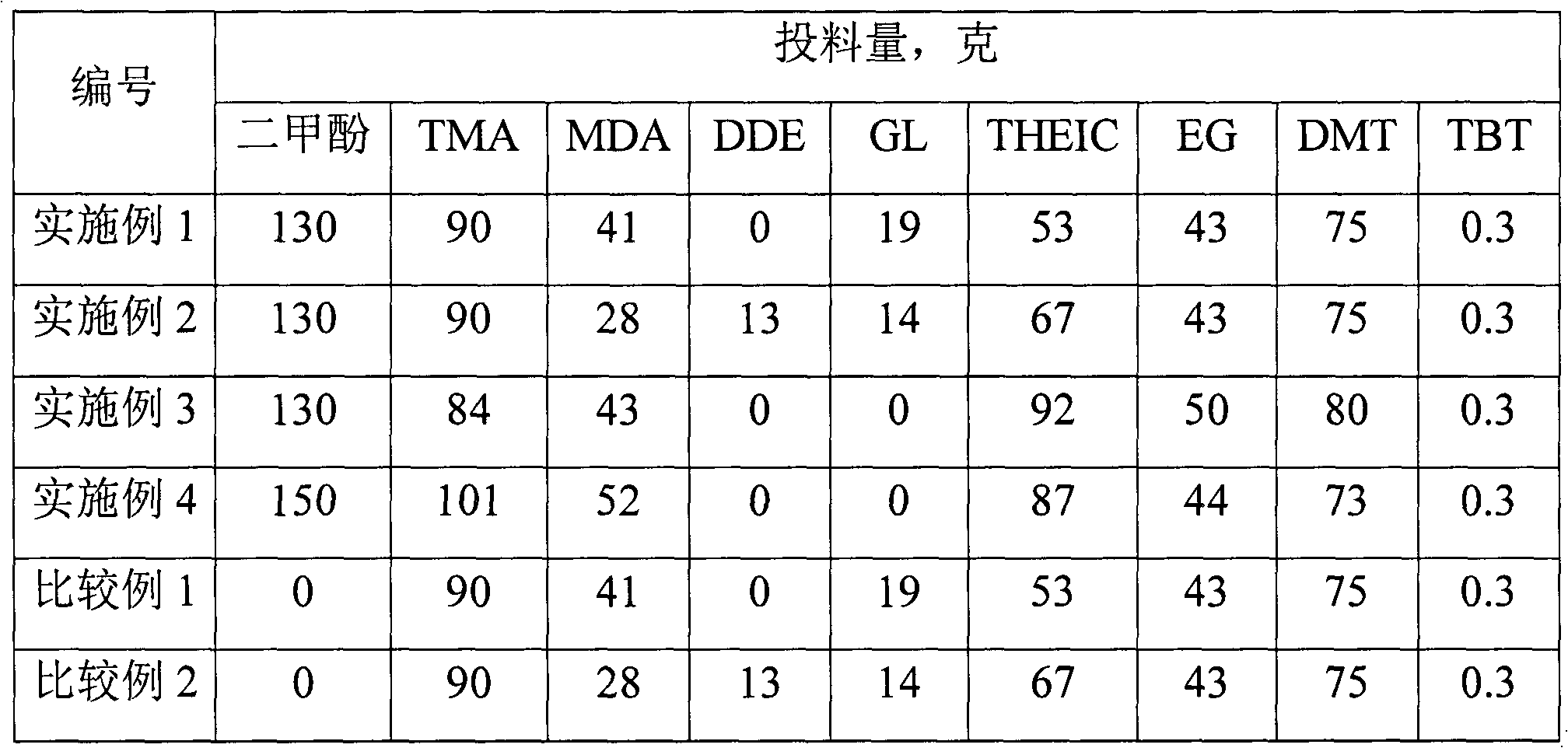

Examples

Embodiment

[0040] Add xylenol and trimellitic anhydride into a 1000ml three-neck flask, heat, raise the temperature to 155°C and keep it warm for half an hour to dissolve the trimellitic anhydride. (At the same time the aromatic diamine is divided into six equal parts). Add the first aromatic diamine, keep it at 155°C, and keep it warm for half an hour. The reactant changes from transparent to yellow and turbid; then add the second amount of aromatic diamine, keep it at 155°C, and keep it warm for half an hour; Parts of aromatic diamine until all six parts of aromatic diamine are added. After all the aromatic diamines have been added, the temperature is raised to 178° C., and the temperature is kept for 2 hours. The water generated by imidization is continuously discharged. Imination is complete.

[0041] Then, add dihydric alcohol, trihydric alcohol and dibasic acid, and raise the temperature to 180°C until the reactant is transparent. After the reactant became transparent, it was k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com