Liner material for improving interfacial bonding of HTPB propellant and preparation method thereof

An interface bonding and propellant technology, which is applied in the field of lining, can solve the problems of unreported application, and achieve the effects of improving adhesion, good mechanical properties and process performance regulation, and saving charging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

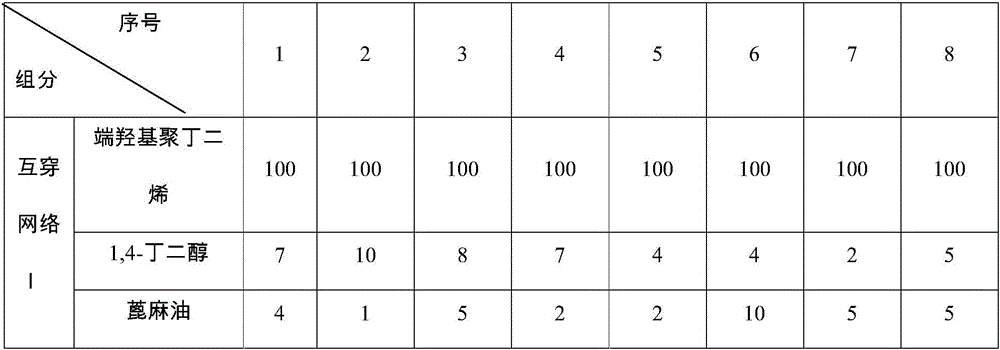

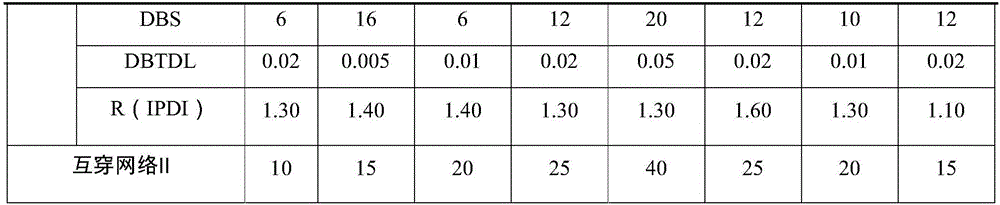

[0050] At room temperature, 100g of ethylene oxide-tetrahydrofuran copolyether, 7g of 1,4-butanediol, 4g of castor oil, 0.02g of DBTDL and 6.0g of DBS were added and stirred thoroughly after each addition. Then add the curing agent with R=1.30 at room temperature and stir evenly. Finally, 10.0 g of epoxy resin was added at room temperature, stirred evenly, and vacuum degassed for 20 minutes to prepare a new type of interpenetrating network lining. The mechanical properties of the body can be measured by making the lining film; the tear-off strength is tested by making the polyether propellant / lining layer / thermal insulation layer bonding test piece, and the results are listed in Table 2.

Embodiment 2~8

[0052] Press the prescription of Table 1, prepare and test with the method same as Example 1, and the results are listed in Table 2.

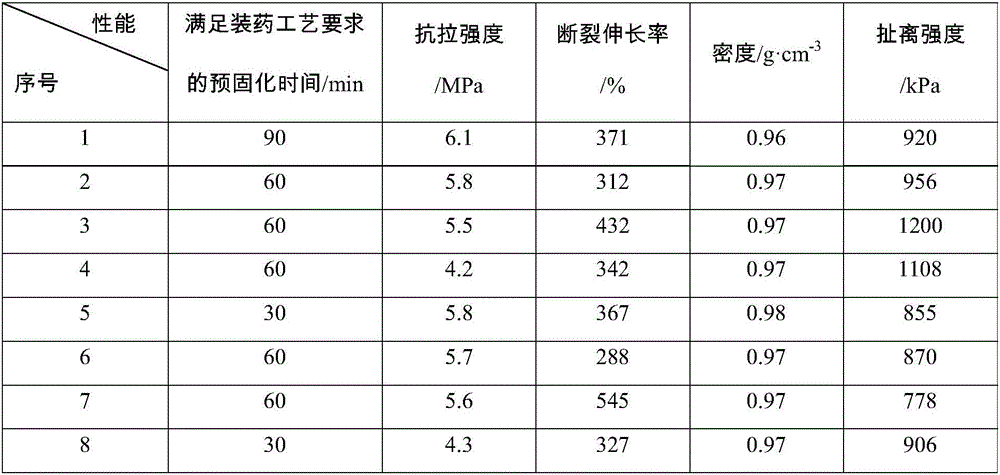

[0053] Each embodiment performance test result of table 2

[0054]

[0055] From the experimental results in Table 2, it can be seen that the liner formed by the liner of the present invention has excellent bonding performance with the butylated hydroxyl propellant, and can meet the requirements of the engine charge on the interface bonding reliability. At the same time, the liner has a short pre-curing time, which can shorten the charging process time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com