Polyurethane sealing material and preparation method thereof

A sealing material, polyurethane technology, applied in the field of polyurethane, can solve problems such as poor adhesion, complicated operation process, drop, etc., and achieve good adhesion performance, long gel time, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

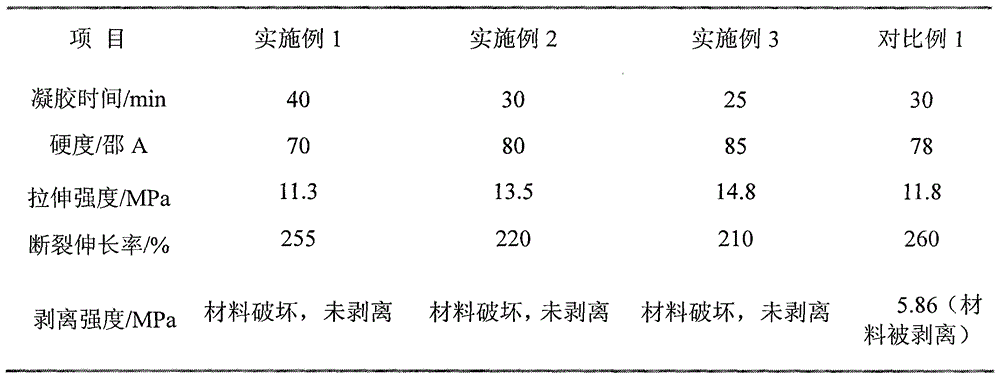

Embodiment 1

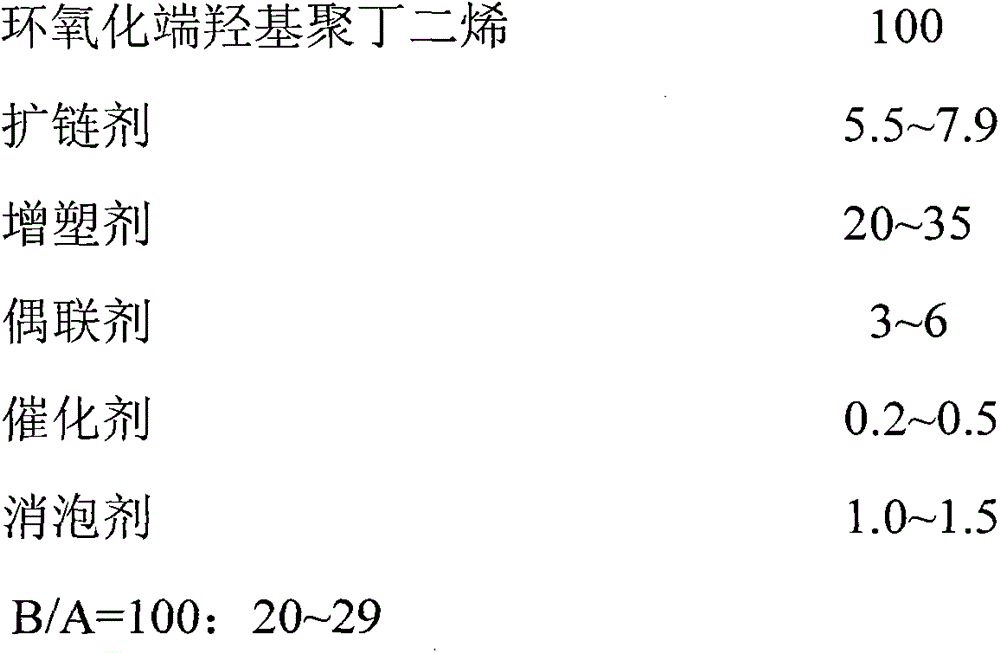

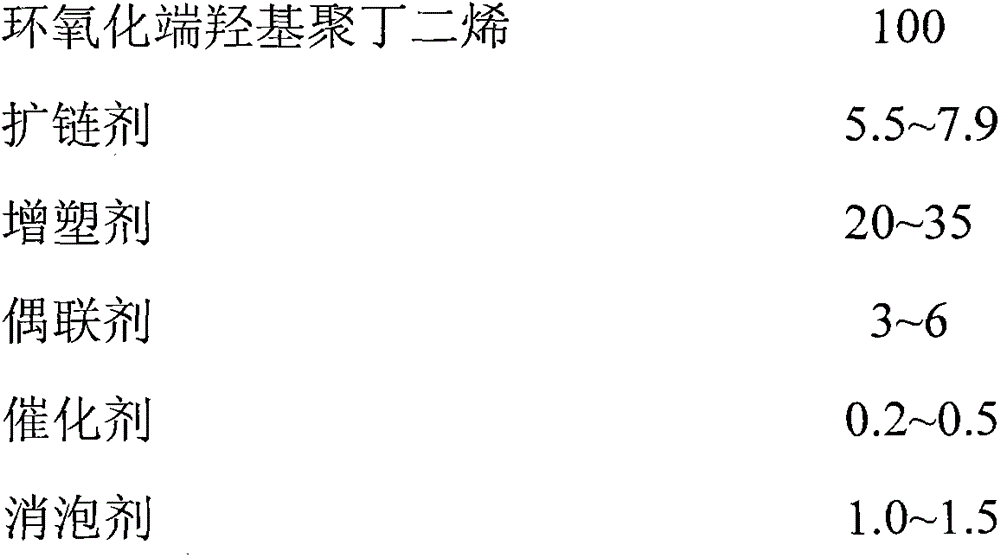

[0023] Preparation of component A: 100 parts of carbodiimide-modified MDI, 10 parts of dimethoxyethyl phthalate, mixed at room temperature for 1 hour, and vacuum defoaming to obtain component A.

[0024] Preparation of component B: 100 parts of epoxidized hydroxyl-terminated polybutadiene (hydroxyl value 0.8 mmol / g, epoxy value 1.5 mmol / g), 35 parts of dimethoxyethyl phthalate, chain extender 5.5 parts (N, N'-bis(2-hydroxypropyl) aniline / 1,4-butanediol=1 / 1), after mixing and dehydrating, add 3 parts of epoxy silane, 0.5 part of stannous octoate and 1.0 parts of polysiloxane, after mixing evenly, the B component is obtained.

[0025] At room temperature, adjust the ratio of components A and B to B / A=100:20, mix the two components thoroughly, defoam, inject into a mold at room temperature, gel in 40 minutes, and test performance after 7 days at room temperature.

Embodiment 2

[0027] Preparation of component A: 100 parts of carbamate-modified MDI, 15 parts of dioctyl phthalate, mixed at room temperature for 1 hour, and vacuum defoaming to obtain component A.

[0028] Preparation of component B: 100 parts of epoxidized hydroxyl-terminated polybutadiene (hydroxyl value 1.2mmol / g, epoxy value 1.9mmol / g), 25 parts of dioctyl phthalate, 7 parts of chain extender ( N,N'-bis(2-hydroxypropyl)aniline / 1,4-butanediol=3 / 1), after mixing and dehydrating, add 6 parts of epoxy silane, 0.3 parts of stannous octoate and modified polymer 1.0 parts of siloxane, after mixing evenly, the B component is obtained.

[0029] At room temperature, adjust the dosage ratio of components A and B to B / A=100:24.8, mix the two components thoroughly, defoam, inject into a mold at room temperature, gel for 30 minutes, and test performance after 7 days at room temperature.

Embodiment 3

[0031] Preparation of component A: 100 parts of carbodiimide-modified MDI, 20 parts of dimethoxyethyl phthalate, mixed at room temperature for 1 hour, and vacuum defoamed.

[0032] Preparation of component B: 100 parts of epoxidized hydroxyl-terminated polybutadiene (hydroxyl value 2.0 mmol / g, epoxy value 3.5 mmol / g), 20 parts of dimethoxyethyl phthalate, chain extender 7.9 parts (N,N'-bis(2-hydroxypropyl)aniline / 1,4-butanediol=1 / 1), after mixing and dehydrating, add 4.5 parts of aminopropylsilane, 0.2 parts of stannous octoate and 1.5 parts of polysiloxane, after mixing evenly, the B component is obtained.

[0033] At room temperature, the mass ratio of B / A is 100:29, fully mixed, defoamed, injected into a mold at room temperature, gelled in 25 minutes, and left at room temperature for 7 days to measure performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com