Polyurethane damping cushion with high cold resistance and preparation method thereof

The technology of cold-resistant polyurethane and shock-absorbing pad is applied in the field of polyurethane material synthesis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

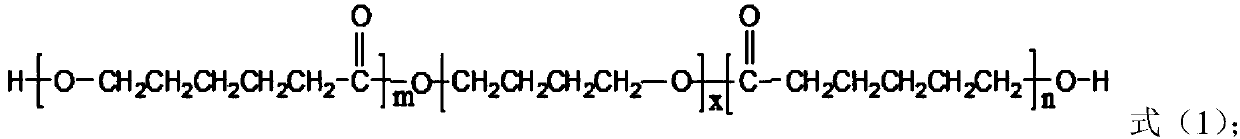

[0063] The invention relates to a high cold-resistant polyurethane shock-absorbing pad. The polyurethane shock-absorbing pad is formed by mixing and crosslinking components A and B. Wherein, A component is polyol composition, comprises the raw material of following weight portion:

[0064] The average functionality is 2, and the number average molecular weight is 67 parts of caprolactone-modified polytetrahydrofuran ether diols of 2000;

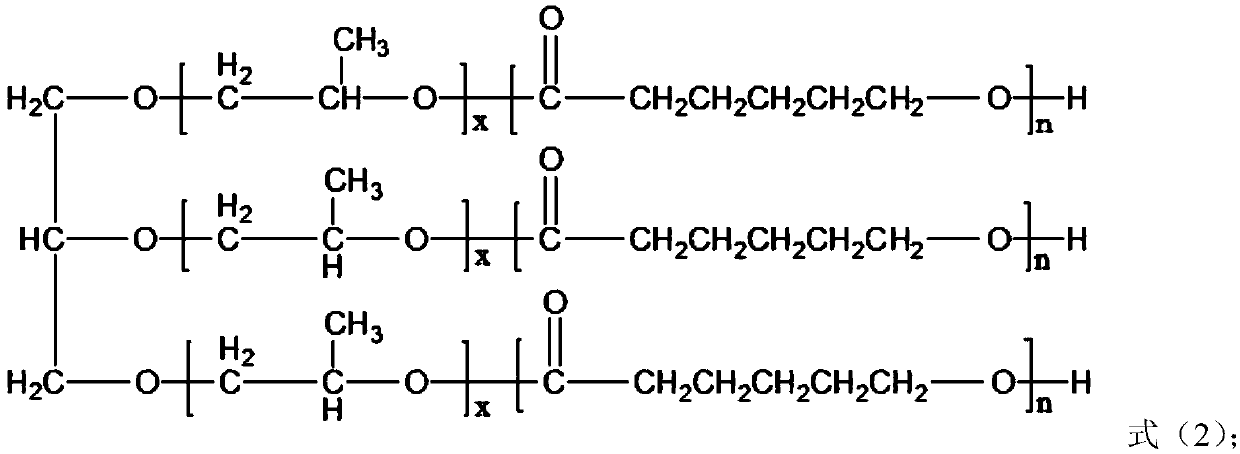

[0065] Average functionality is 20 parts of polyoxypropylene trihydric alcohol that number average molecular weight is 6000;

[0066] 8 parts of hydroxyl-terminated polybutadiene having an average functionality of 2.2 and a number average molecular weight of 2800;

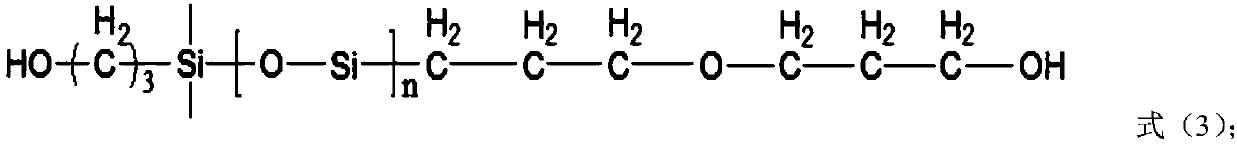

[0067] 5 parts of terminal primary hydroxysiloxanes with an average functionality of 2 and a number average molecular weight of 2000;

[0068] 6 parts of 1,4-butanediol;

[0069] 0.97 parts of a catalyst composed of 0.85 parts of Dabco33-LV (American Air Chemicals, composed of ...

Embodiment 2

[0082] The invention relates to a high cold-resistant polyurethane shock-absorbing pad. The polyurethane shock-absorbing pad is formed by mixing and crosslinking components A and B. Wherein, A component is polyol composition, comprises the raw material of following weight portion:

[0083] 52.5 parts of caprolactone-modified polytetrahydrofuran ether diols with an average functionality of 2 and a number-average molecular weight of 1000;

[0084] The average functionality is 3, the number average molecular weight is 32.5 parts of polyoxypropylene trihydric alcohols of 6000;

[0085] 10 parts of hydroxyl-terminated polybutadiene having an average functionality of 2.2 and a number-average molecular weight of 2800;

[0086] 5 parts of terminal primary hydroxysiloxanes with an average functionality of 2 and a number average molecular weight of 2000;

[0087] 5 parts of ethylene glycol;

[0088] 0.97 parts of a catalyst composed of 0.85 parts of Dabco33-LV (American Air Chemicals...

Embodiment 3

[0101] The invention relates to a high cold-resistant polyurethane shock-absorbing pad. The polyurethane shock-absorbing pad is formed by mixing and crosslinking components A and B. Wherein, A component is polyol composition, comprises the raw material of following weight portion:

[0102] The average functionality is 2, and the number average molecular weight is 58 parts of caprolactone-modified polytetrahydrofuran ether diols of 2000;

[0103] Average functionality is 25 parts of polyoxypropylene trihydric alcohols that number average molecular weight is 4800 for 3;

[0104] 12 parts of hydroxyl-terminated polybutadiene having an average functionality of 2.2 and a number average molecular weight of 3200;

[0105] 5 parts of terminal primary hydroxysiloxanes with an average functionality of 2 and a number average molecular weight of 2000;

[0106] 5.6 parts of ethylene glycol;

[0107] 0.97 parts of a catalyst composed of 0.85 parts of Dabco33-LV (American Air Chemicals, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com