Polyurethane resin potting adhesive with high bonding strength and preparation method thereof

A polyurethane resin, high-adhesion technology, used in polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve the harsh requirements of thermal shock resistance, poor adhesion of PA66, difficult to withstand parking sensors, etc. problems, to achieve the effects of excellent electrical properties, good bonding properties, and low internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

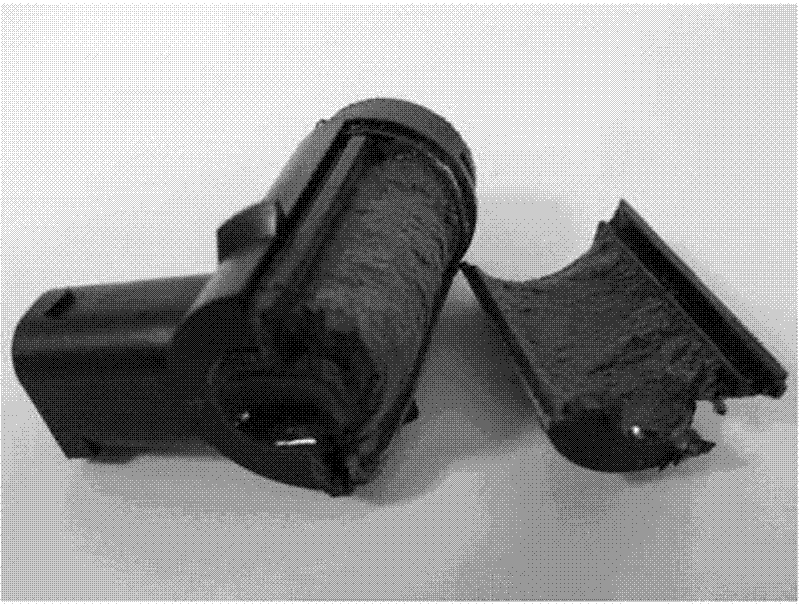

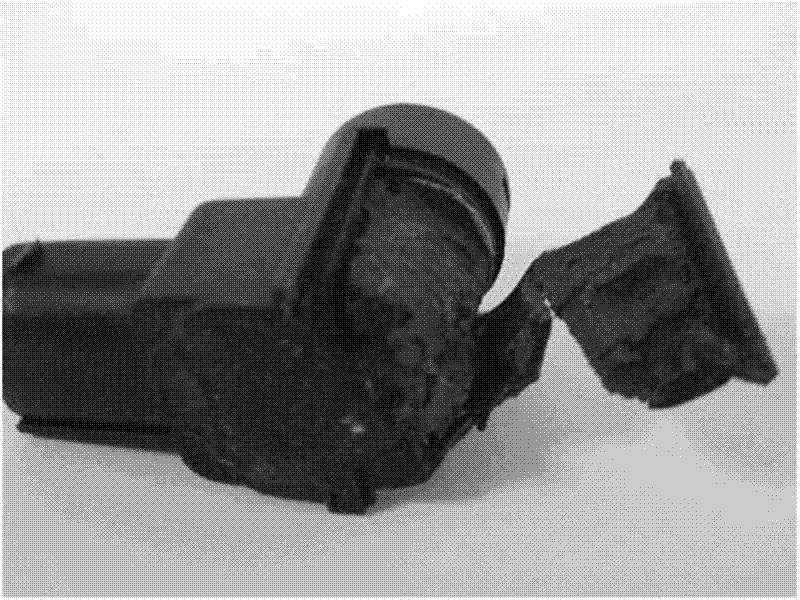

Image

Examples

Embodiment 1

[0043] A high bonding strength polyurethane resin potting glue, consisting of component A and component B, in parts by weight,

[0044] Component A: 31 parts of castor oil (hydroxyl equivalent: 345, average hydroxyl functionality: 2.7), 12 parts of polyoxypropylene glycol (average molecular weight: 1000), 0.2 parts of accelerator (DBU), 48 parts of inorganic powder, 8.2 parts of effect additives;

[0045] Component B: 26.7 parts of hydroxyl-terminated polybutadiene (hydroxyl value 0.9mmol / g, number average molecular weight 2300), MDI (MDI-100HL, 4,4'-MDI content ≥ 90%, NCO content 29%) 33.3 parts, accelerator (DABCO 33LV) 0.03 parts, flame retardant 40 parts;

[0046] 8.2 parts of the above-mentioned effect additives are composed of 0.35 parts of black pigment, 0.5 parts of defoaming agent, 0.6 parts of wetting agent, 0.25 parts of anti-settling agent, and 6.5 parts of water-removing agent.

[0047] The preparation method of the above-mentioned high bond strength polyurethan...

Embodiment 2

[0051] A high bonding strength polyurethane resin potting glue, consisting of component A and component B, in parts by weight,

[0052] Component A: 20.5 parts of castor oil (hydroxyl equivalent: 345, average hydroxyl functionality: 2.7), 7.9 parts of polyoxypropylene glycol (average molecular weight: 1000), 0.2 parts of accelerator (DBU), 62.6 parts of inorganic powder, 8.2 parts of effect additives;

[0053] Component B: 26.7 parts of hydroxyl-terminated polybutadiene (hydroxyl value 0.9mmol / g, number average molecular weight 2300), MDI (MDI-100HL, 4,4'-MDI content ≥ 90%, NCO content 29%) 33.3 parts, accelerator (DABCO 33LV) 0.03 parts, flame retardant 40 parts;

[0054] 8.2 parts of the above-mentioned effect additives are composed of 0.35 parts of black pigment, 0.5 parts of defoaming agent, 0.6 parts of wetting agent, 0.25 parts of anti-settling agent, and 6.5 parts of water-removing agent.

[0055] The preparation method of the above-mentioned high bond strength polyur...

Embodiment 3

[0059] A high bonding strength polyurethane resin potting glue, consisting of component A and component B, in parts by weight,

[0060] Component A: 31 parts of castor oil (hydroxyl equivalent 345, average hydroxyl functionality 2.7), 12 parts of polyoxypropylene glycol (average molecular weight 1000), 0.2 parts of accelerator (DBU), 48 parts of inorganic powder, 8.2 parts of effect additives;

[0061] Component B: 20.5 parts of hydroxyl-terminated polybutadiene (hydroxyl value 0.9mmol / g, number average molecular weight 2300), MDI (MDI-100HL, 4,4'-MDI content ≥ 90%, NCO content 29%) 25.5 parts, accelerator (DABCO 33LV) 0.03 parts, flame retardant 54 parts;

[0062] 8.2 parts of the above-mentioned effect additives are composed of 0.35 parts of black pigment, 0.5 parts of defoamer, 0.6 part of wetting agent, 0.25 parts of anti-settling agent, and 6.5 parts of water-removing agent.

[0063] The preparation method of the above-mentioned high bond strength polyurethane resin pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com