Preparation for low molecular weight hydroxy-terminated polybutadiene

A hydroxyl polybutadiene, low molecular weight technology, applied in the field of chemical synthesis, can solve the problems of many preparation steps, low yield, incomplete hydrolysis of protective groups, etc., and achieve good mechanical properties and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

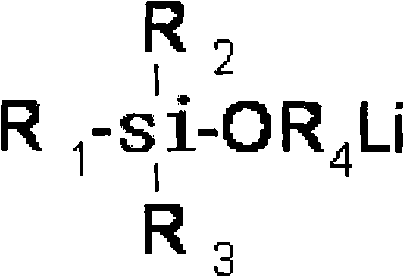

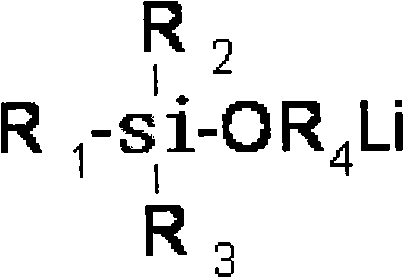

[0022] (1) Preparation of initiator tert-butyldimethylsiloxane n-propyllithium

[0023] In a 250ml three-necked flask, add 38g (0.4mol) 3-chloro-1-propanol, 60g (0.4mol) tert-butyldimethylsilyl chloride, 100ml N, N-dimethylformamide and 38g ( 0.44mol) of imidazole, reacted at 5°C for 30 minutes, and stirred at room temperature for 6 hours under nitrogen protection. Add 350ml of n-hexane, then wash with 5% aqueous sodium bicarbonate solution three times, and separate the n-hexane layer. After drying with calcium hydride, the solvent was evaporated by rotary evaporation, and a colorless liquid was obtained by chromatographic column separation with a yield of 93%.

[0024] Under Ar atmosphere, add 8g (1.01mol) of lithium and 50ml of cyclohexane into the reaction flask into a 250ml three-necked flask equipped with a condenser, a constant pressure dropping funnel, and magnetic stirring, and then add 22.3g (0.107mol) of t 50 ml of a cyclohexane solution of butyl-(3-chloropropoxy)d...

Embodiment 2

[0028] (1) Preparation of tert-butyldimethylsiloxane n-propyllithium

[0029] With embodiment 1.

[0030] (2) Preparation of hydroxyl-terminated polybutadiene

[0031] Under the protection of high-purity argon, take 3.5ml of n-propyllithium tert-butyldimethylsilyl ether and add it to a 250ml reaction bottle containing 6g of butadiene and 50ml of cyclohexane, polymerize at 25°C for 5h, and then use Inject 3ml of propylene oxide into the syringe and continue the reaction at 50°C for 1 hour. After the reaction is completed, stop the reaction with 2ml of ethanol. The glue is precipitated and separated in ethanol. Dissolve the lower glue in 40ml of tetrahydrofuran, and add 0.5g of ammonium fluoride to remove the protecting group. Then, settle and separate with ethanol, and dry at 50°C and -0.1MPa for 8 hours to obtain a hydroxyl-terminated polybutadiene telechelic polymer. GPC measured Mn=5100, Mw / Mn=1.07, and the average functionality was 2.0 by HNMR analysis.

Embodiment 3

[0033] (1) Preparation of triethylsilyl ether n-propyllithium initiator

[0034] In a 250ml three-necked flask, 38g (0.4mol) of 3-chloro-1-propanol, 61g (0.4mol) of triethylchlorosilane, and 80ml of tetrahydrofuran were sequentially added. Then the N, N-dimethylformamide (30ml) solution containing 38g (0.44mol) imidazole was added dropwise to the reaction system within 30min at 5°C. 2 Stir at room temperature under protection for 6 hours. 350ml of cyclohexane was added, and then washed three times with 5% aqueous sodium bicarbonate solution, and the cyclohexane layer was separated. After drying with calcium hydride, the solvent was evaporated by rotary evaporation, and a colorless liquid was obtained by column separation with a yield of 90%.

[0035] Under Ar atmosphere, add 8g (1.01mol) lithium, 100ml cyclohexane and 22.3g (0.107mol) triethyl-(3- Chloropropoxy)-silane was added into the reaction flask, the temperature was raised to 60°C, and stirred for 2h. The crude prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average functionality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com