Method for preparing polybutadiene-base water polyurethane and modified emulsion thereof

A technology of water-based polyurethane and polybutadiene, which is applied in the field of preparation of polybutadiene-based water-based polyurethane and its modified emulsion, can solve the problems of low stability and compatibility, and does not involve water-based products, and achieve mechanical Performance improvement, good low temperature resistance, good film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

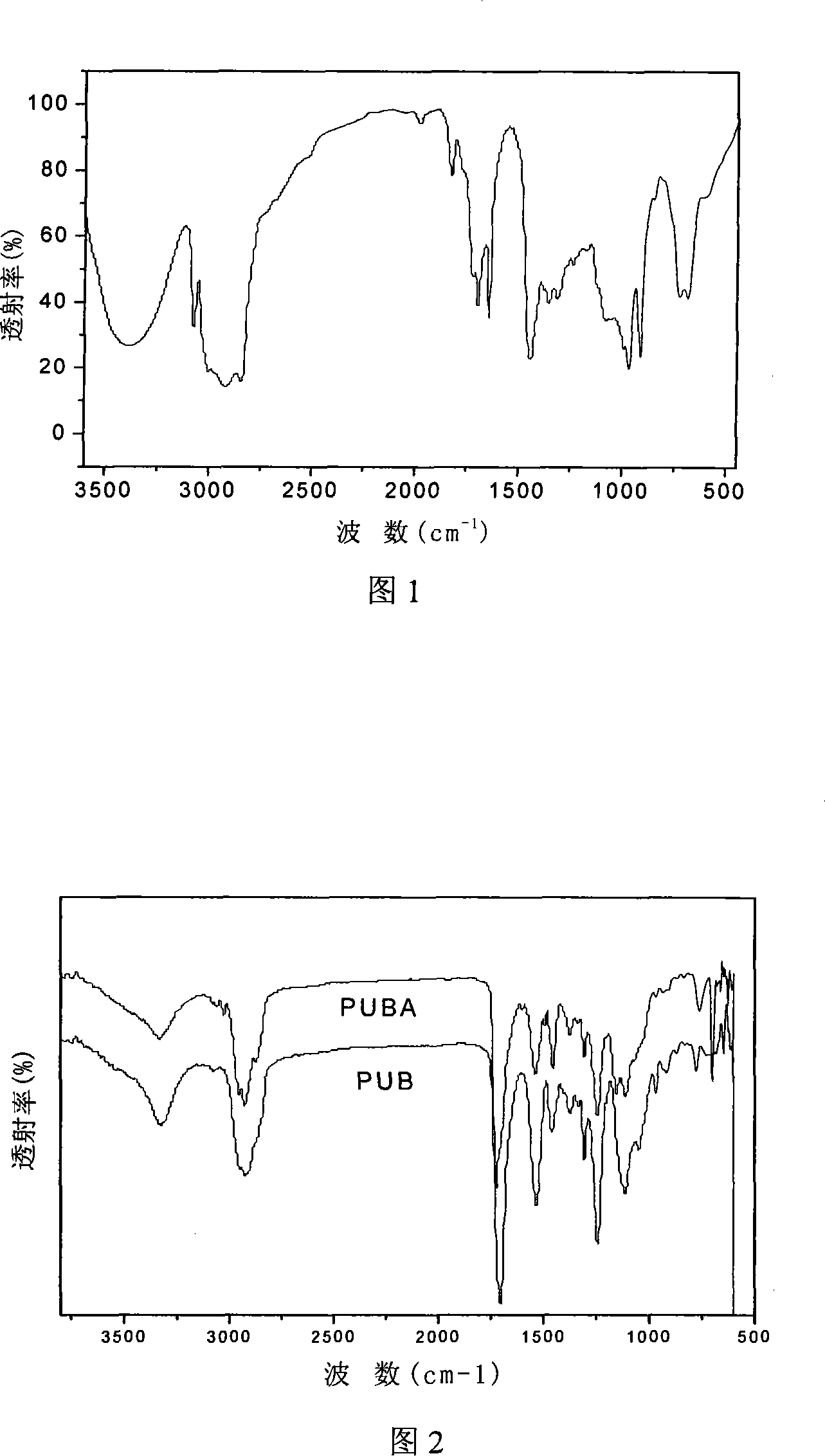

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of polybutadiene-based waterborne polyurethane and its modified emulsion

[0026] 1. Preparation of polybutadiene-based waterborne polyurethane

[0027] Weigh 16 grams of toluene diisocyanate, 30 grams of N-220 polyoxypropylene glycol after vacuum dehydration and 15 grams of hydroxyl-terminated polybutadiene liquid rubber after vacuum dehydration, add them to a 250ml three-necked flask, and react at a constant temperature of 85°C for 1 hour , followed by adding 2.8 grams of dimethylol propionic acid, reacting at a constant temperature of 85°C for 1 hour, and finally adding 3.4 grams of diethylene glycol, one drop of dibutyltin dilaurate and stannous octoate, 50ml of acetone, and reacting at a constant temperature of 60°C for 4 Hours later, cool down to 25°C and discharge to obtain a prepolymer, pour the prepolymer into a high-speed shear disperser, pour 2.8 g of triethylamine under the condition of 800 rpm, react for 1 minute, and then pour Ad...

Embodiment 2

[0032] Embodiment 2: the preparation of polybutadiene-based waterborne polyurethane

[0033]Weigh 21 grams of toluene diisocyanate, 30 grams of N-210 polyoxypropylene glycol after vacuum dehydration and 15 grams of hydroxyl-terminated polybutadiene liquid rubber after vacuum dehydration, add them to a 250ml three-necked flask, and react at 60°C for 3 hours Add 3.3 grams of dimethylolpropionic acid and react at 85°C for 1 hour; finally add 3.6 grams of diethylene glycol, 0.9 grams of trimethylolpropane, 2 drops of dibutyltin dilaurate, and 50 ml of acetone. After reacting at 70°C for 4 hours, cool down to 20°C and discharge to form a prepolymer. Pour the prepolymer into a high-speed shear disperser, pour 3g of triethylamine under the condition of 1000 rpm, and react 1 Minutes, then pour 140g of water and stir for 2 minutes to obtain a white water-based polyurethane emulsion with a solid content of 30%; the obtained water-based polyurethane emulsion is distilled off under reduce...

Embodiment 3

[0034] Embodiment 3: the preparation of polybutadiene-based waterborne polyurethane

[0035] Weigh 15 grams of isophorone diisocyanate, 10 grams of N-220 polyamide after vacuum dehydration and 20 grams of hydroxyl-terminated polybutadiene liquid rubber after vacuum dehydration, add them to a 250ml three-necked flask, and react at 90°C for 1 hour; Then add 2.4 grams of dimethylol propionic acid, react at 70°C for 2 hours, finally add 1.5 grams of ethylene glycol, one drop of dibutyltin dilaurate, stannous octoate, 55ml of acetone, react at 50°C for 5 hours, then cool down to 45 The prepolymer was obtained by discharging at ℃, and the prepolymer was poured into a high-speed shear disperser, and 1.8 g of triethylamine was poured under the condition of 2000 rpm, reacted for 0.5 minutes, and then poured into 130 g of water and stirred for 3 minutes , to obtain a white water-based polyurethane emulsion with a solid content of 35%; the obtained water-based polyurethane emulsion was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com