Preparation method of composite superhydrophobic coating possessing abrasion-resistance performance

A technology of super-hydrophobic coating and anti-wear performance, which is applied in the field of preparation of composite super-hydrophobic coatings, and can solve problems such as super-hydrophobic surface failure, rough surface structure damage, and super-hydrophobic function failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

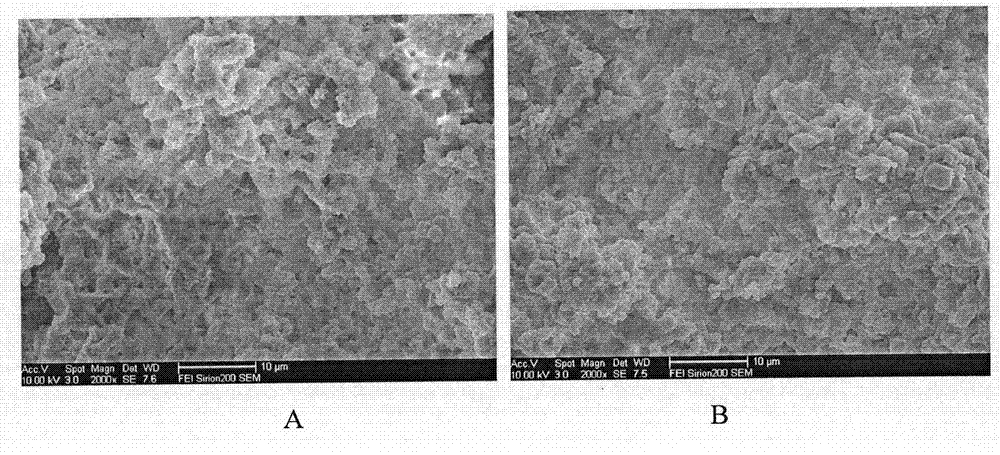

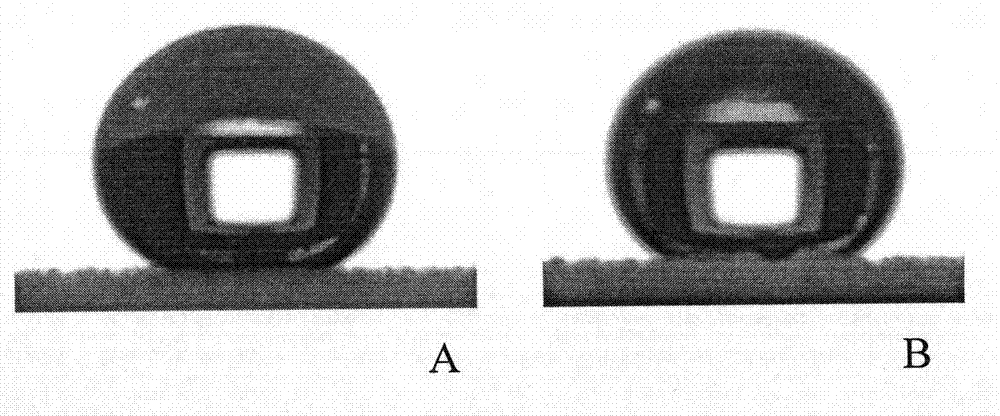

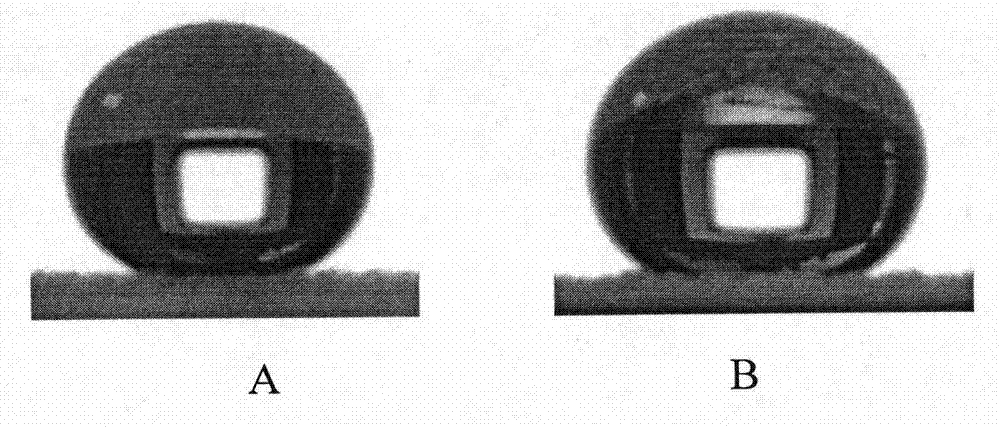

Embodiment 1

[0018] The specific steps are: 1) Weigh 3.2 grams of hydroxyl-terminated polybutadiene and 1 gram of toluene diisocyanate and place them in a round-bottomed flask, react at 70° C. for 1 hour, then add 135.8 grams of acetone to dilute to form polyurethane with a solid content of 3%. Prepolymer solution; 2) Slowly add the above polyurethane prepolymer solution dropwise to 70 grams of ethylenediamine in acetone solution with a mass content of 0.25%, to obtain a milky white polyurethane sol, and keep stirring at 300 rpm during the dropping process Speed; 3) Add 4.2 grams of epoxy resin E-44, 0.588 grams of amino silicone oil and 0.22 grams of diethylenetriamine to the polyurethane sol, and mix evenly to obtain a spraying liquid; place the spraying liquid in the spray gun irrigation and use 0.6MPa compressed air Sprayed on the glass substrate, after 12 hours at 20 degrees Celsius, the obtained coating is a composite super-hydrophobic coating, and the contact angle of the coating is ...

Embodiment 2

[0021] The specific steps are: 1) Weigh 3.2 grams of hydroxyl-terminated polybutadiene and 1 gram of toluene diisocyanate and place them in a round-bottomed flask, react at 70° C. for 1 hour, then add 135.8 grams of acetone to dilute to form polyurethane with a solid content of 3%. Prepolymer solution; 2) Slowly add the above polyurethane prepolymer solution dropwise to 56 grams of ethylenediamine in acetone solution with a mass content of 0.2%, to obtain a milky white polyurethane sol, and keep stirring at 500 revolutions per minute during the dropping process Speed; 3) Add 5.88 grams of epoxy resin E-44, 0.63 grams of amino silicone oil and 0.5 grams of diethylenetriamine to the polyurethane sol, and mix evenly to obtain the spraying liquid; place the spraying liquid in the spray gun irrigation and use 0.6MPa compressed air After spraying on the glass substrate and leaving it at 20 degrees Celsius for 12 hours, the resulting coating is a composite super-hydrophobic coating, a...

Embodiment 3

[0024] 1) Weigh 4.5 grams of hydroxyl-terminated polybutadiene and 1 gram of toluene diisocyanate in a round-bottomed flask, react at 70°C for 1 hour, then add 104.5 grams of acetone to dilute into a polyurethane prepolymer solution with a solid content of 5%. ; 2) Slowly add the above-mentioned polyurethane prepolymer solution dropwise to 55 grams of ethylenediamine in acetone solution with a mass content of 0.25%, to obtain a milky white polyurethane sol, and keep a stirring speed of 400 revolutions per minute during the dropping process; 3) Add 3.3 grams of epoxy resin E-44, 0.74 grams of amino silicone oil and 0.56 grams of diethylenetriamine to the polyurethane sol, mix well to obtain a spraying liquid; put the spraying liquid in the spray gun tank, and use 0.6MPa compressed air to spray on the glass substrate , after standing at 20 degrees Celsius for 12 hours, the obtained coating is a composite superhydrophobic coating, and the contact angle of the coating is 165°.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com