Integral heat generation ceramic tile and manufacturing technique thereof

An all-in-one, ceramic tile technology, applied in the field of ceramic tile processing, can solve the problems of complex installation and maintenance, many supporting equipment, and large heat generation, and achieve the effects of good waterproof and moisture-proof performance, simple structure design, and uniform conduction and heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

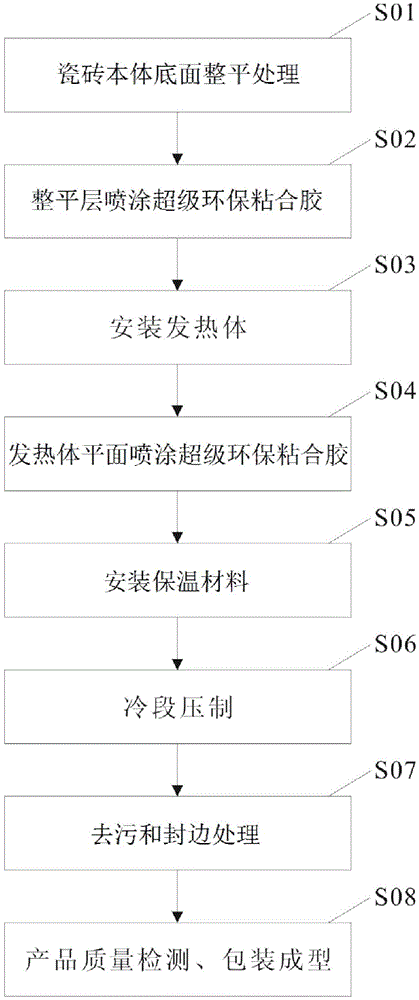

[0026] Below, the present invention will be described in more detail with reference to the drawings and specific embodiments.

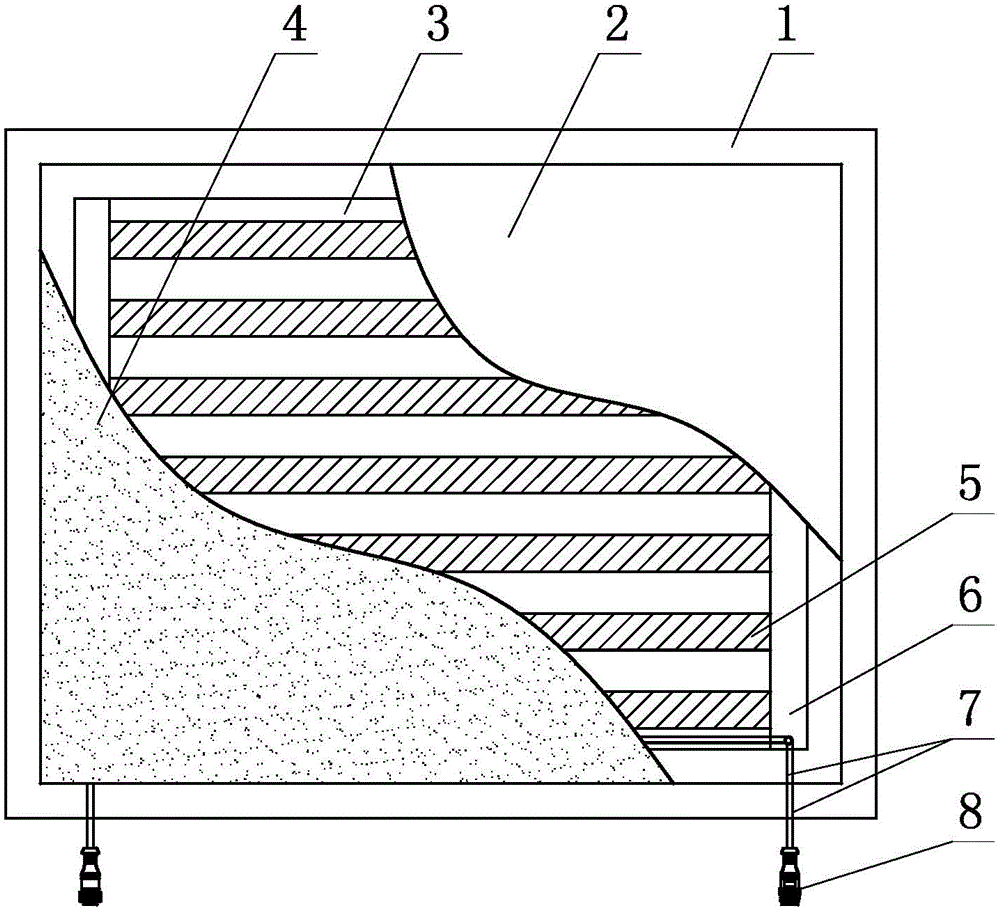

[0027] Such as figure 1 , figure 2 , image 3 As shown, its composition is composed of a tile body 1, a leveling layer 2, a heating element 3, a thermal insulation substrate 4, a heating sheet 5, a conductive plate 6, a connecting wire 7, and a waterproof connector 8.

[0028] The structural features of specific embodiments are:

[0029] An integrated heating tile, its structural features are: comprising a tile body 1, a heating element 3, and a thermal insulation substrate 4, the heating element is an epoxy resin heating element composed of several heating sheets 5 arranged horizontally, the number of The two ends of the block heating sheet are provided with conductive plates 6 in parallel, and the connection wires 7 drawn from the wire connection ends at one end of the two conductive plates are connected with the waterproof connector 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com