Double-layered quay crane for loading and unloading containers

A technology of containers and quay cranes, applied in the field of double-layer quay cranes, which can solve the problems of low container loading and unloading efficiency, and achieve the effects of simple structure, improved rigidity, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

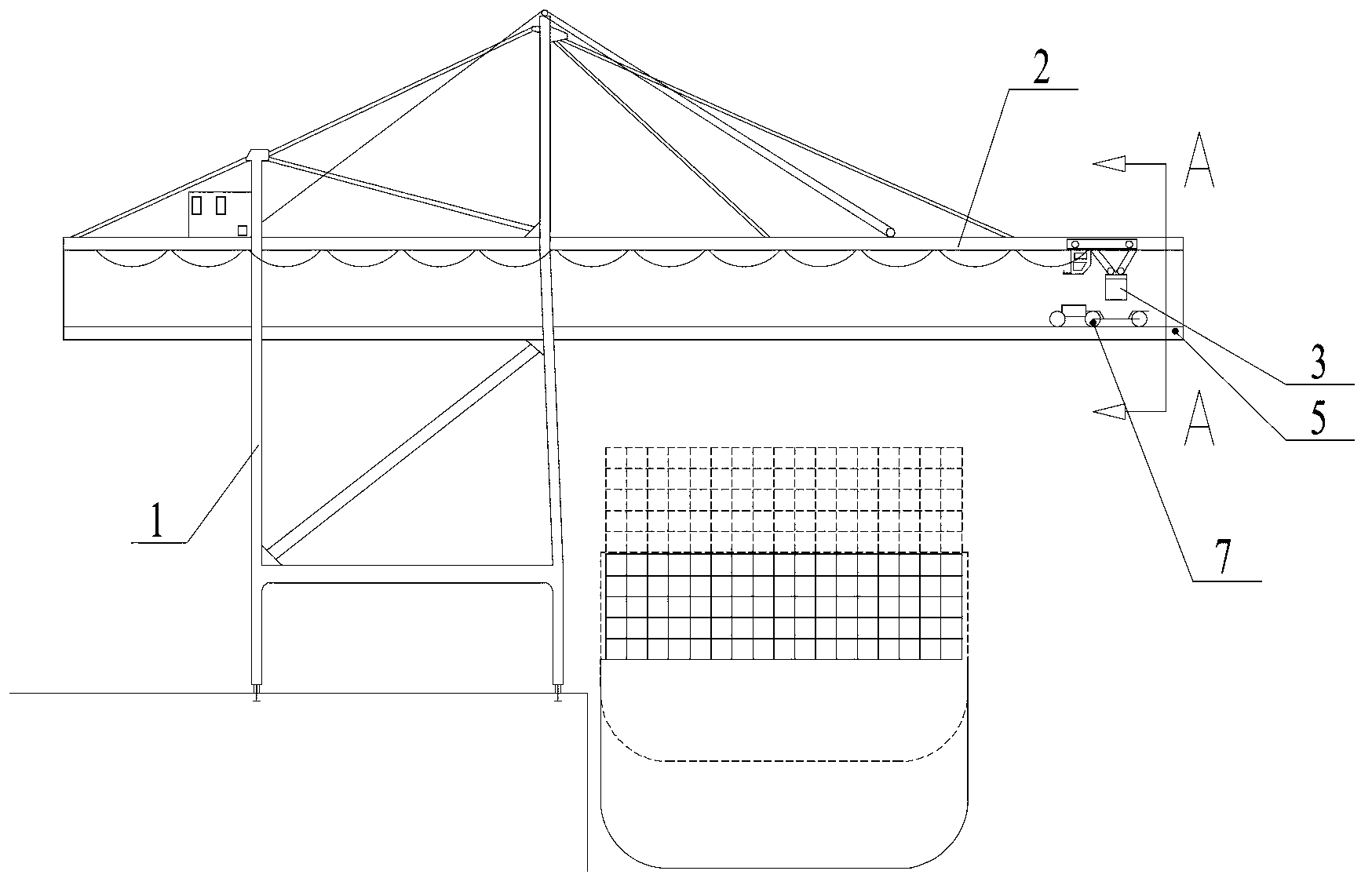

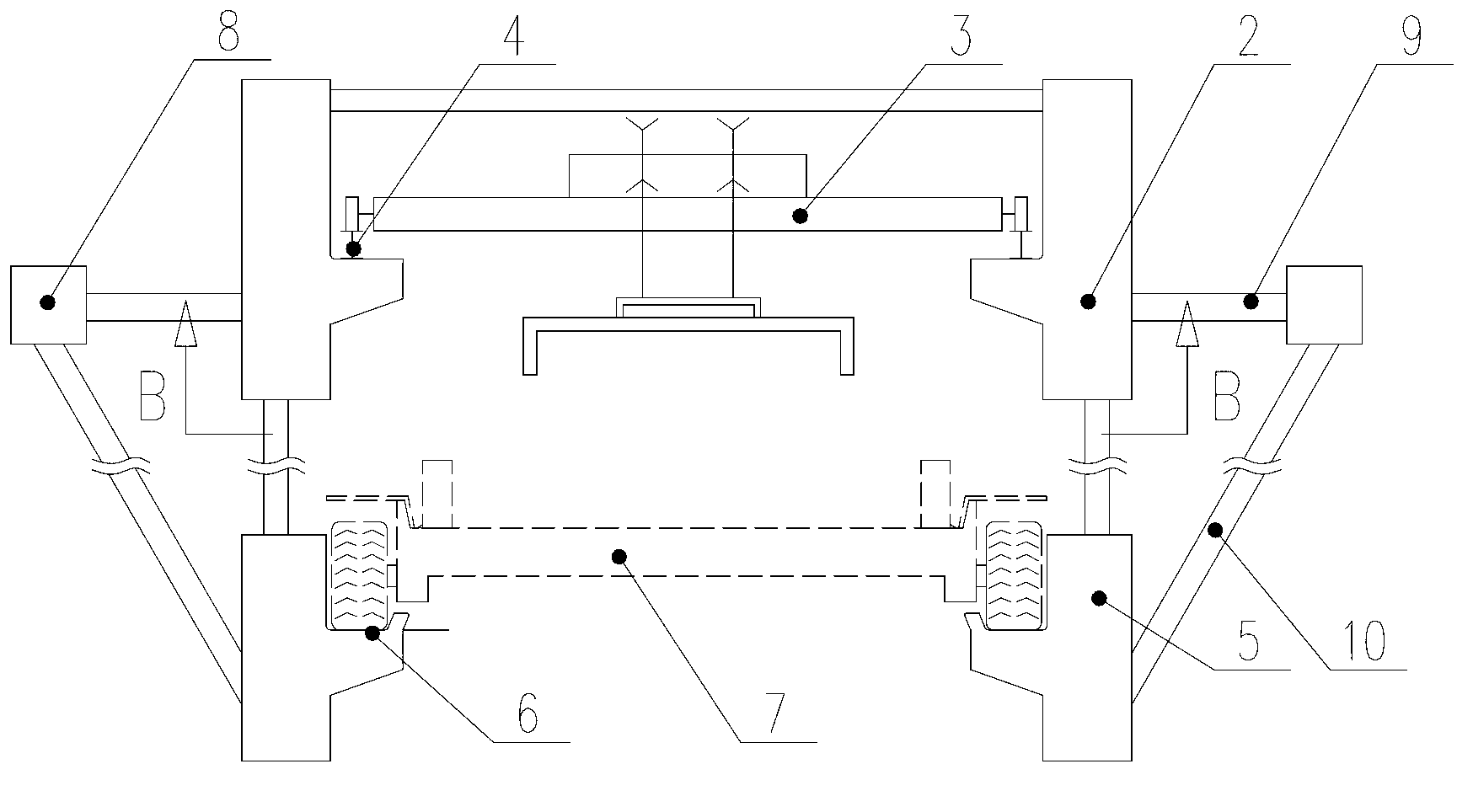

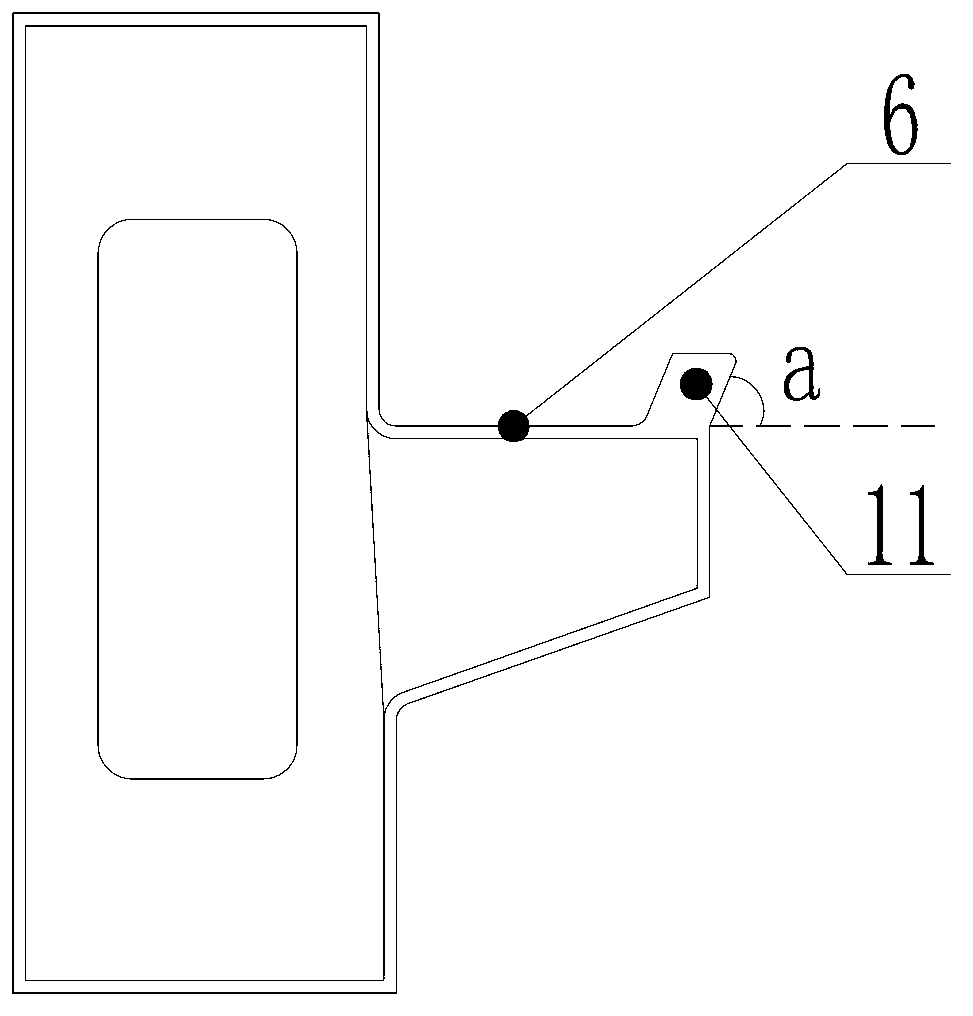

[0024] Embodiment 1 of the present invention, such as figure 1 As shown, a double-deck quay bridge for container loading and unloading includes a gantry-type outrigger 1, a main traveling girder 2 and a lifting trolley 3. The gantry-type outrigger 1 is provided with two main traveling girders 2, each The inner side of the main walking girder 2 is provided with a walking track 4, and the lifting trolley 3 is arranged on the walking track 4, and two transfer vehicle walking girders 5 arranged parallel to it are arranged directly below the main walking girder 2. The inboard of car walking girder 5 is all provided with the walking track 6 of band baffle, and transfer car 7 is located on the walking track 6 of band baffle.

[0025] The distance between the main traveling girder 2 and the transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com