Optical touch module

A touch module, optical technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems affecting the accuracy of light intensity changes of optical sensors, light reflection leakage, optical In order to improve the efficiency of light use, improve accuracy, and prevent light leakage, it can solve problems such as touch failure of the type touch module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

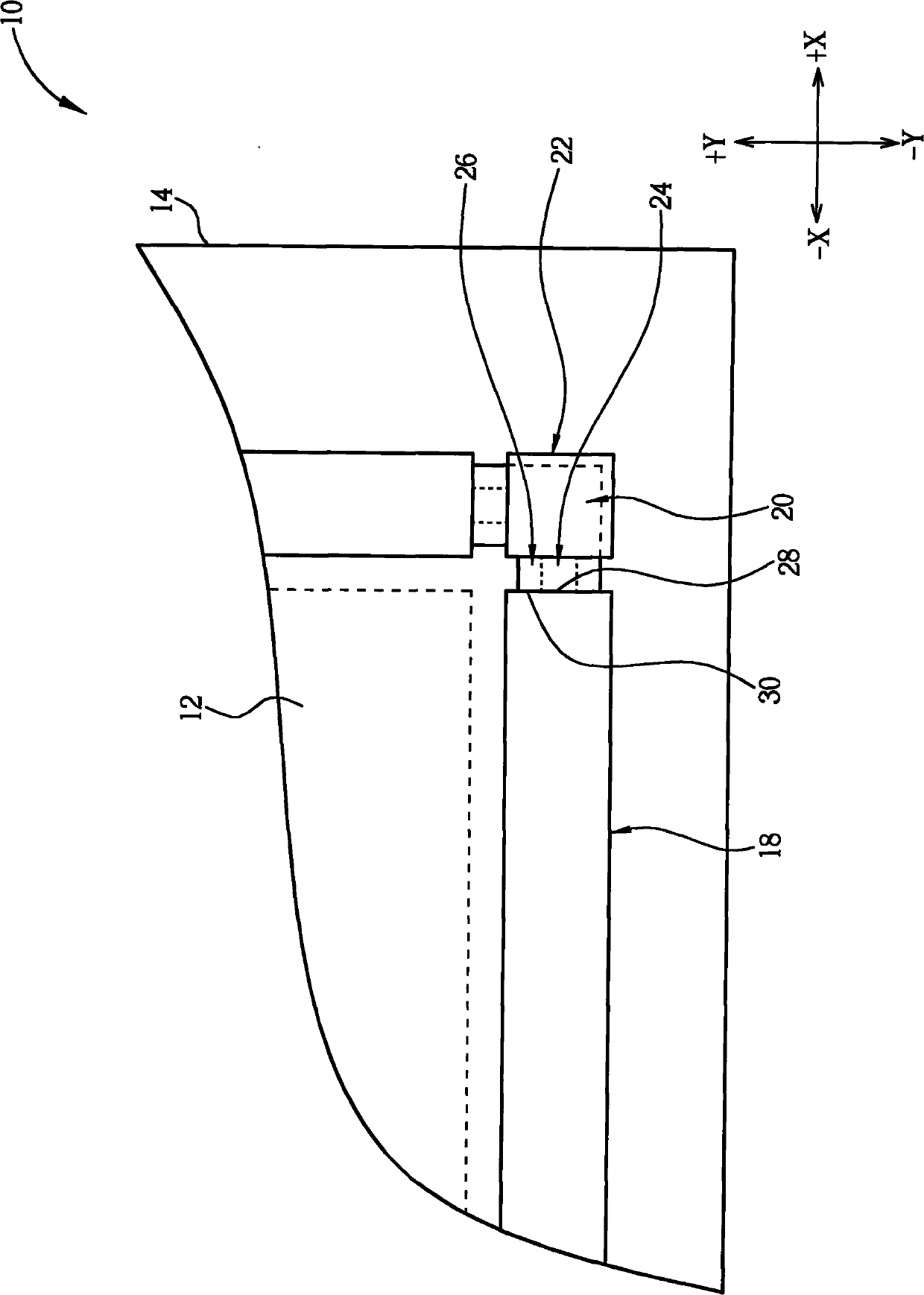

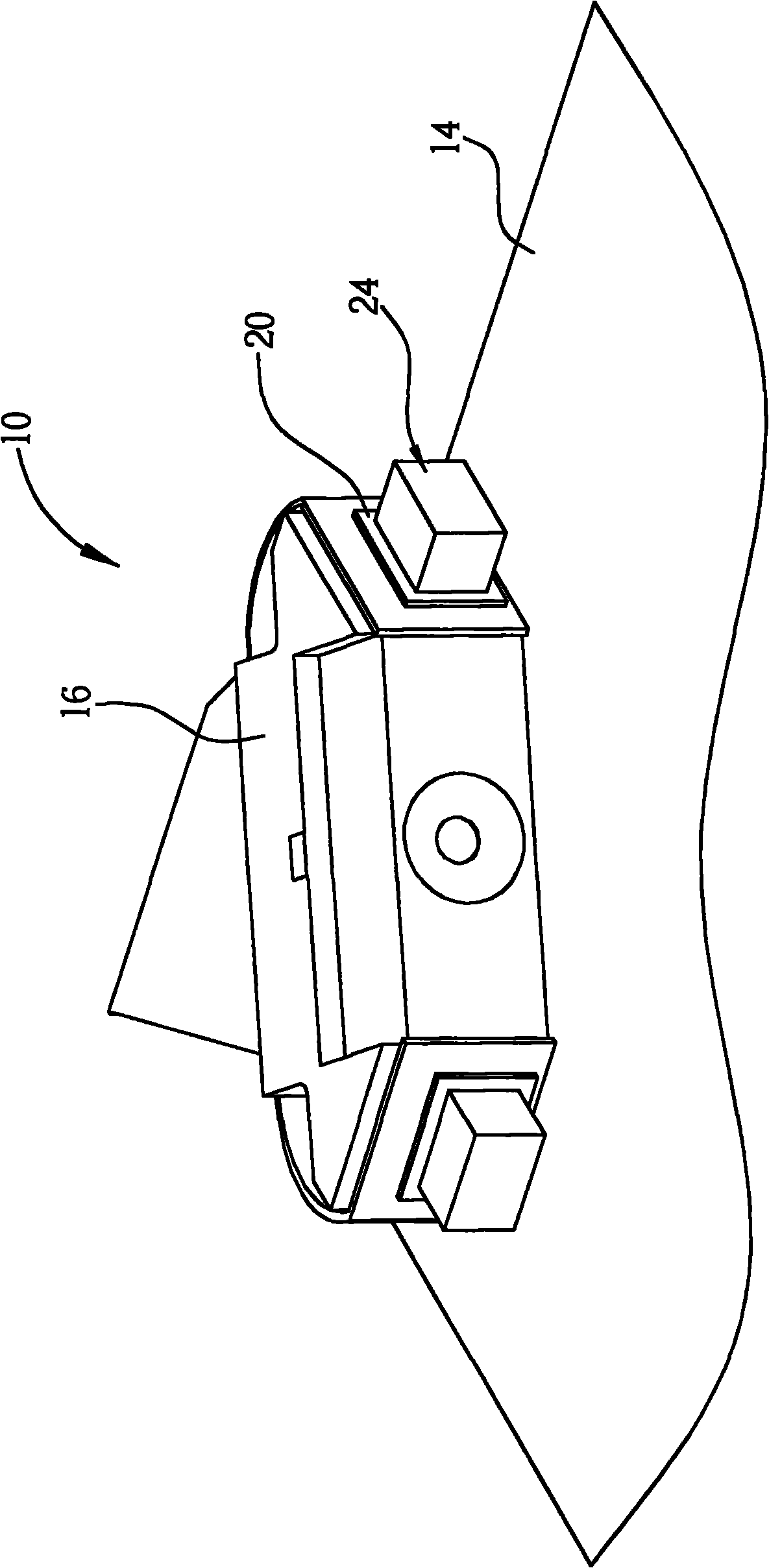

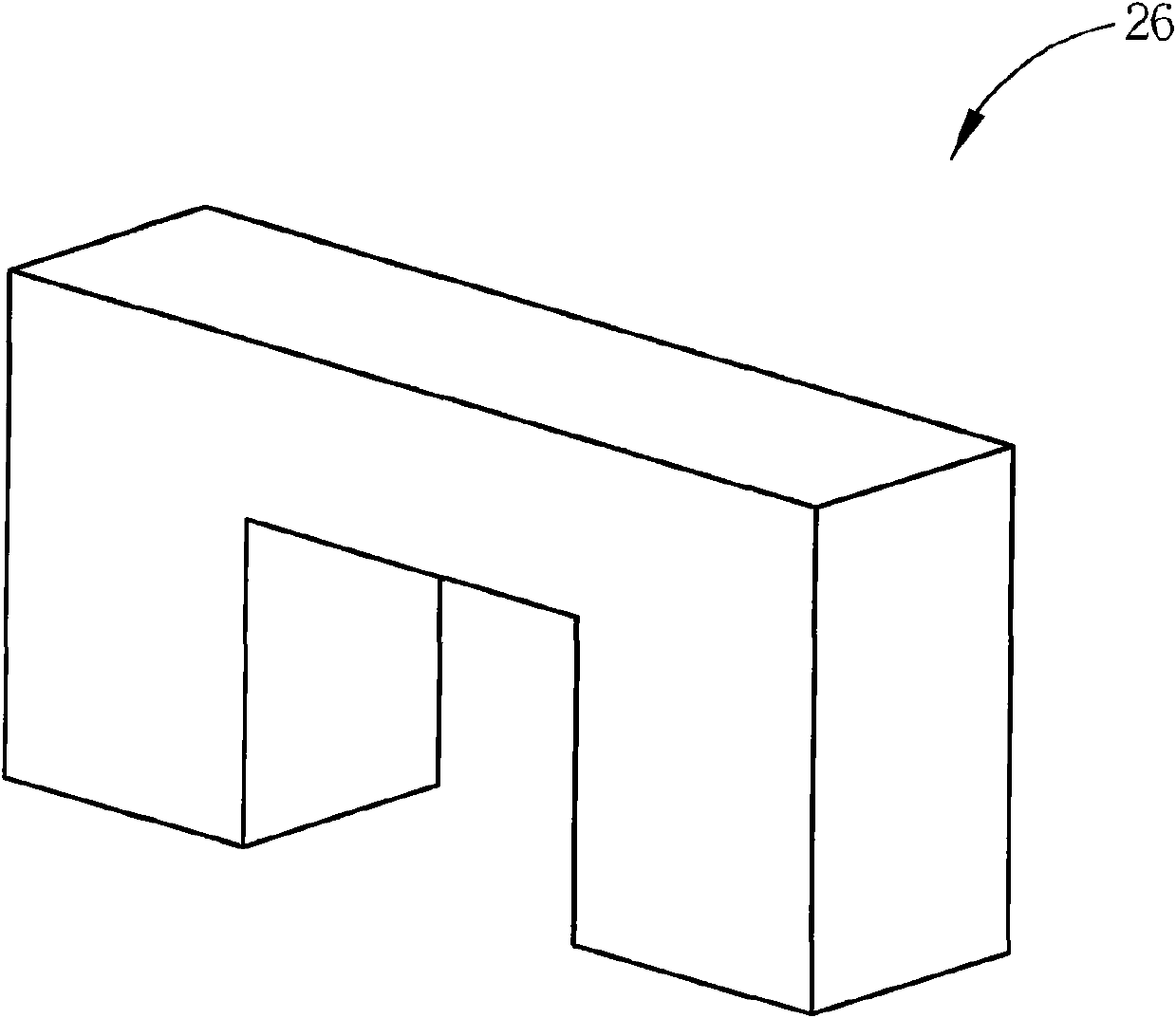

[0027] see figure 1 , which is a schematic diagram of the optical touch module 10 proposed according to the first embodiment of the present invention, represented by figure 1 It can be seen that the optical touch module 10 includes a touch surface 12, a substrate 14, and at least one optical sensor 16 (in figure 1 Show two in), at least one light guide structure 18 (in figure 1 Show four in), at least one elastic member 20 (in figure 1 Show six in), at least one fixed seat 22 (in figure 1 Show two in), at least one light emitting unit 24 (in figure 1 Eight are shown in ), and at least one light-shielding structure 26 (in figure 1 Eight are shown in the figure); the touch surface 12 is located on the substrate 14 for touch operation; the substrate 14 is a plate commonly used in optical touch modules, such as glass or transparent acrylic; The optical sensor 16 captures the image of the touch area toward the touch surface 12, and thereby detects the change of light intensity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com