Compressor and manufacturing method thereof

A manufacturing method and compressor technology, which are applied in the direction of mechanical equipment, machine/engine, and process efficiency improvement, etc., can solve the problems of easy deformation due to heat, tilting of the crankshaft, shortening the service life of the motor, etc., to solve the problem of stator and rotor clearance, The effect of improving assembly accuracy and meeting welding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

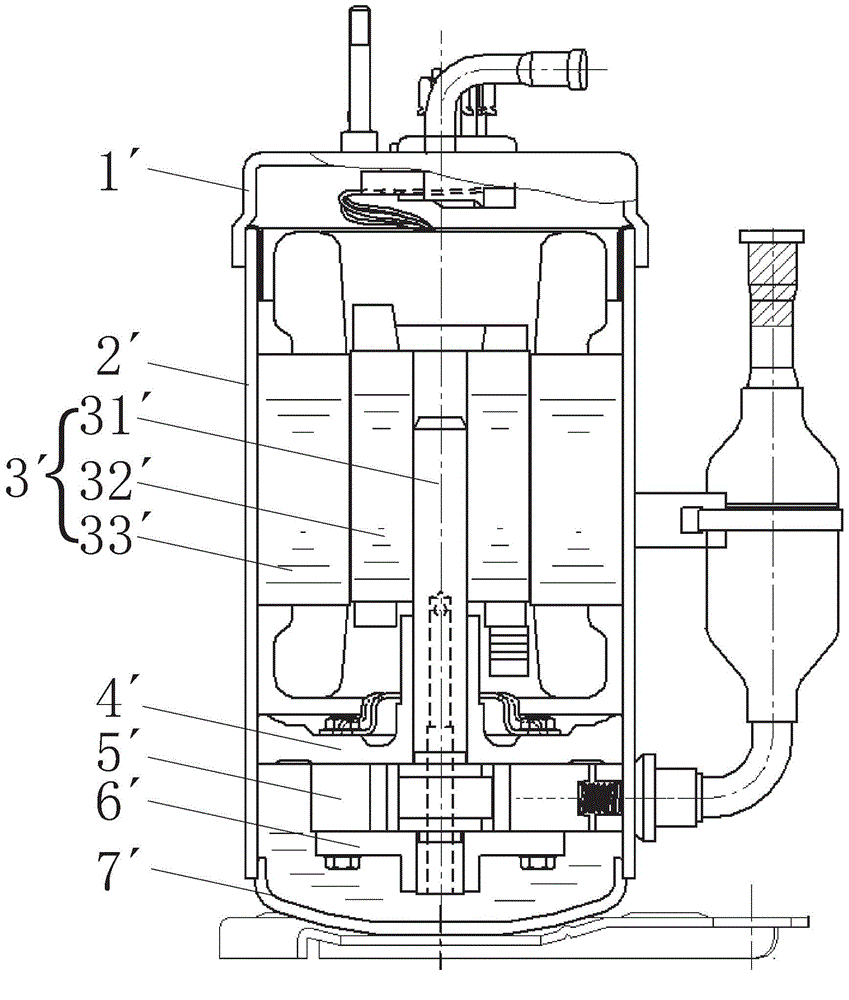

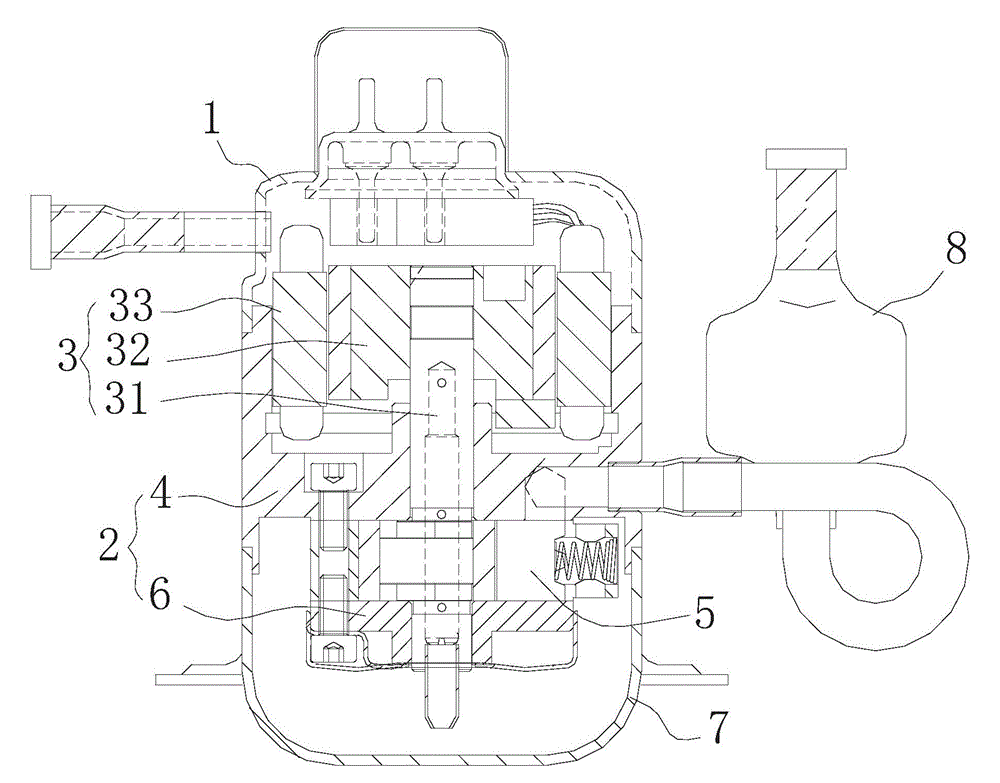

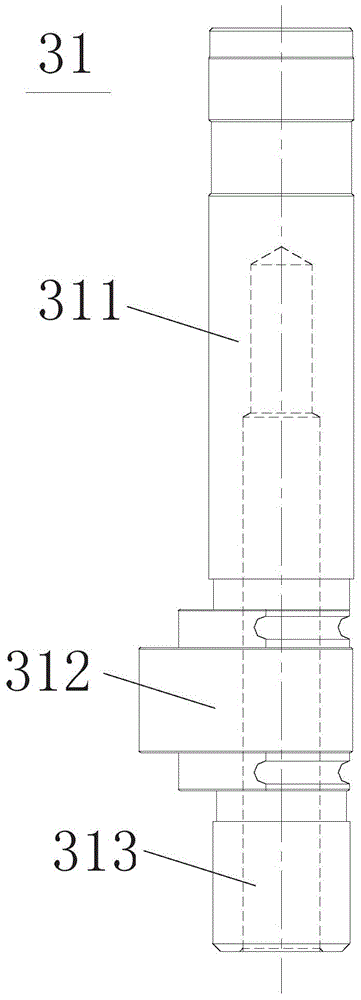

[0070] like figure 2 and image 3 As shown, the compressor of the present invention includes: a housing; the motor 3 is accommodated in the upper space in the housing; the cylinder 5 is accommodated in the lower space in the housing; the crankshaft 31 has a long axis portion 311 and an eccentric portion 312 and short axis portion 313 (such as image 3 As shown), the rotational force of the motor 3 is transmitted to the cylinder 5 to compress the refrigerant; the frame 2 is fixedly connected to the housing by welding; wherein, the frame 2 includes an upper bearing 4 and a lower bearing 6 (due to the present embodiment Take the vertical micro compressor as an example, so the upper bearing 4 is the main bearing, and the lower bearing 6 is the auxiliary bearing), the upper bearing 4, the lower bearing 6 and the cylinder 5 jointly define a compression space and have a support crankshaft 31 respectively Inner hole 44 (see Figure 4 ) and 61 (see Figure 5 ); the upper bearing 4...

no. 2 example

[0080] like Figure 7 As shown, in a modification example, the upper bearing 4a can also be a disc portion 41a with an inner hole 44a and an outer edge portion extending up and down from the outer edge of the disc portion 41a, and the middle cross-section of the upper bearing 4a as a whole is H shape. and Figure 4 and 5 The difference is that if Figure 7 The inner edge portion 45 of the upper bearing 4 is canceled in the upper bearing 4a. After canceling the inner edge part 45, the main part of the upper bearing 4a becomes a simple planar structure (disk part), and the processing becomes easier. Compared with the first embodiment, the inventors have found that: due to the cancellation of the inner edge portion 45, the difference between the inner diameter of the outer edge portion of the compressor of this embodiment and the diameter of the inner hole is smaller than that of a common compressor, and the outer edge portion itself The wall is also relatively thin, so that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com