Upper and lower shell connecting structure and printer comprising same

A connection structure and rotating connection technology, applied in printing devices, printing, etc., can solve problems such as unfavorable operation, complicated assembly, and increased product height and width, so as to avoid misoperation, enhance reliability, and eliminate inability to lock in place Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

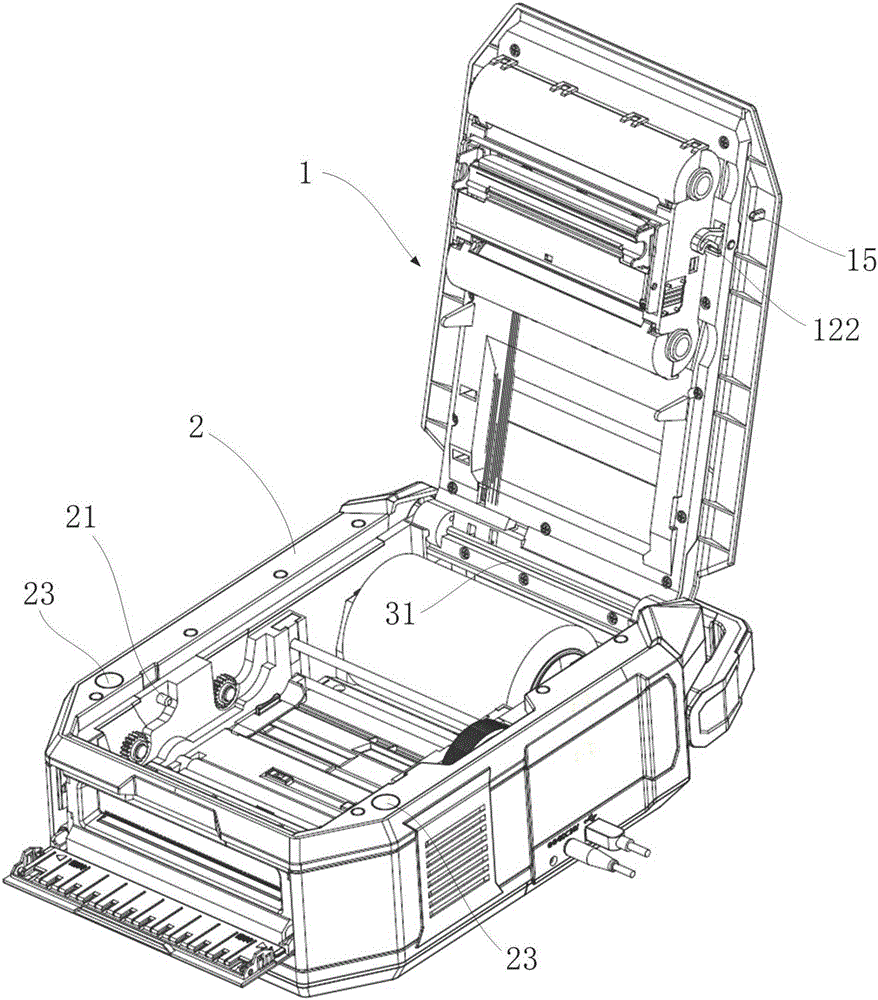

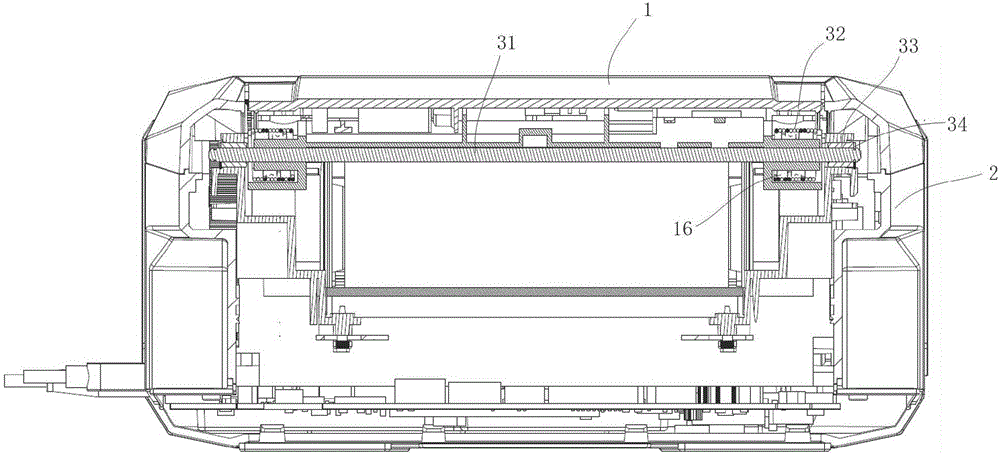

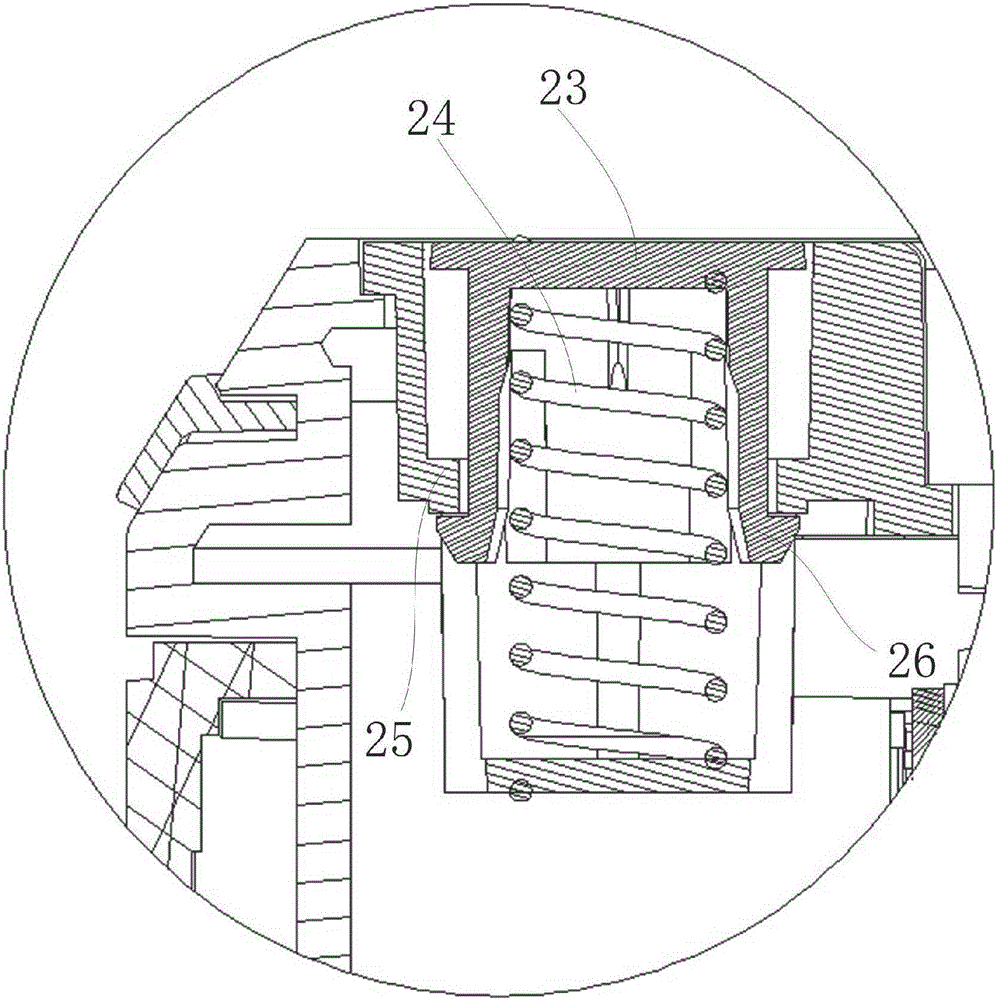

[0075] Such as figure 1 , figure 2and Figure 5 As shown, an upper and lower shell connection structure includes an upper shell assembly 1 and a lower shell assembly 2 that are rotatably connected, and a cover locking mechanism is arranged between the upper shell assembly 1 and the lower shell assembly 2, and the upper shell assembly 1 and the lower shell assembly There is also an auxiliary ejection mechanism between the components 2. When the cover is opened, after the cover locking mechanism is unlocked, the auxiliary ejection mechanism will push the upper shell component 1 out so that there is a gap between it and the lower shell component 2, which is convenient Put your fingers in to open the upper case assembly 1 .

[0076] Further as shown in the figure, the upper shell assembly 1 and the rear end of the lower shell assembly 2 are rotatably connected by a torsion spring 32 and a rotating shaft 31, and accommodation grooves 16 are provided on both sides of the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com