Conductive semi-rigid bearing

A semi-rigid, bearing technology, applied in the field of bearings, can solve the problems that it is difficult to achieve zero clearance processing, reduce the use effect of bearings, and not require high load-bearing capacity, so as to avoid deviation, reduce bearing resistance, and save processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

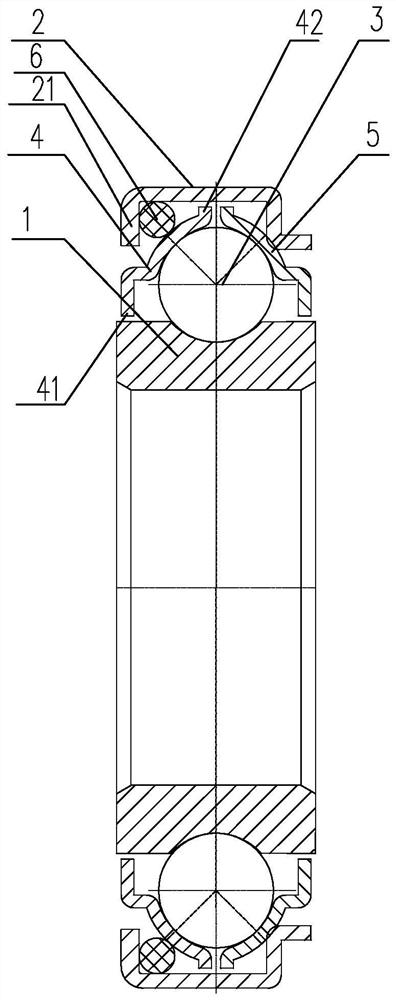

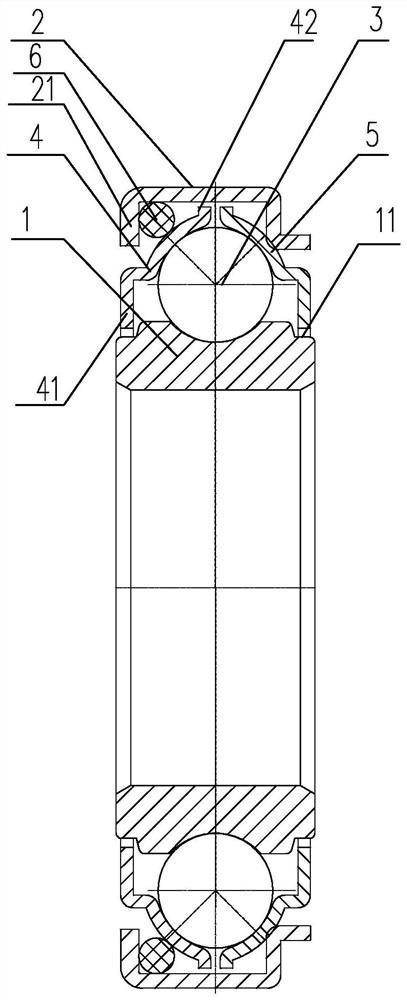

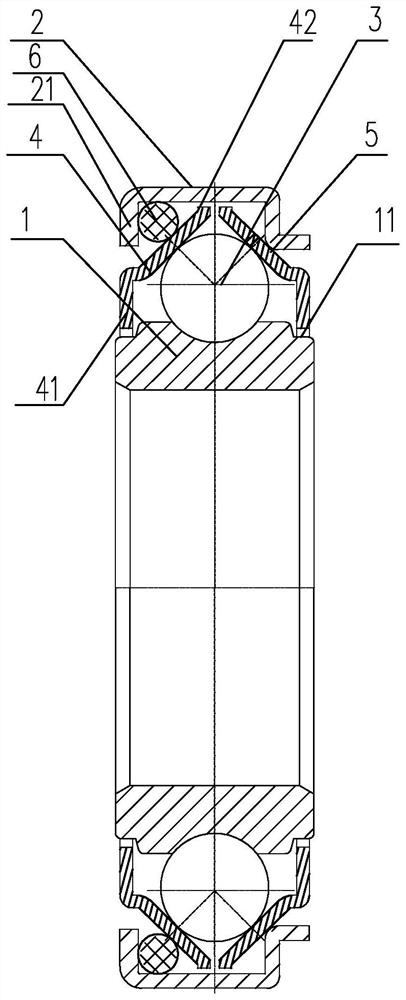

[0019] The first embodiment of the conductive semi-rigid bearing of the present invention is figure 1 Shown: it includes an inner ring 1 and an outer ring 2, a raceway is provided on the outer wall of the inner ring 1, the roller 3 is arranged on the raceway, and a first roller is arranged between the outer ring 2 and the roller 3 A raceway ring 4 and a second raceway ring 5, the first raceway ring 4 and the second raceway ring 5 are respectively arranged on both sides of the roller 3, the first raceway Including a fitting portion for fitting on the outer peripheral surface of the roller 3, the fitting portion is arranged in the form of an arc surface, and an elastic rubber ring 6 is provided in conflict between one end of the outer ring 2 and the first raceway ring 4 , the outer ring 2 is formed with a conflicting portion corresponding to the position of the second raceway ring 5 , and the conflicting portion abuts on the second raceway ring 5 . The beneficial effects of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com