Plunger

A technology of shells and blanks, applied in the directions of fuel injection pumps, mechanical equipment, valve devices, etc., can solve problems such as structural space limitation conflicts, and achieve the effects of simple manufacturability, compact structure, and high load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

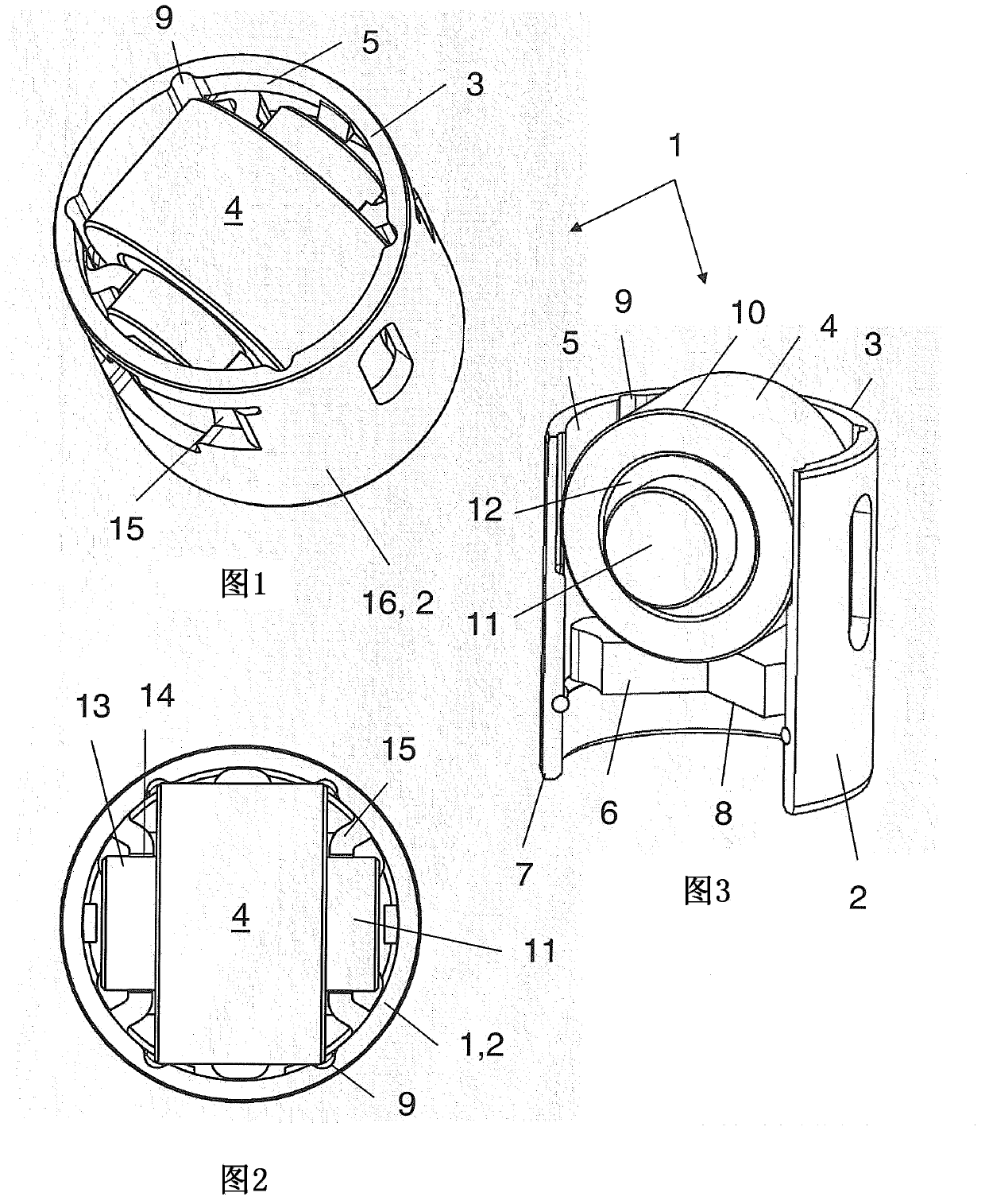

[0016] A tappet 1 of a high-pressure pump for diesel fuel of an internal combustion engine is shown here. The tappet 1 has a cylindrical housing 2 which, in the region of the upper first annular end 3 , accommodates the majority of the roller 4 for striking the travel cam within its inner circumference 5 .

[0017] Axially below the rollers 4 , a separate bridge 6 passes through the deep-drawn housing 2 from a steel sheet. The bridge is present as a separate stamped plate, whose bottom side 8 facing the lower second ring end 7 of the housing 2 serves as abutment for the pump piston as tappet follower.

[0018] In the direction of the first ring end 3 , the bridge 6 is supported on the secant joists of the diametrically opposite setback region 15 of the housing 2 .

[0019] As shown outside, the rollers 4 run via roller bearings 12 on pins 11 . The pins 11 are accommodated with their ends 13 in part-cylindrical receptacles 14 of the respective indented regions 15 of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com