Method for filling and sealing rollers of integrated special-shaped crossed roller bearing

A cross-roller bearing, integrated technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problem of affecting the bearing capacity of the reducer, restricting the mass production and promotion of products, and the lack of roller filling and sealing. Solve and other problems to achieve the effect of enhancing rigidity and strength, increasing installation space, and increasing roller size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and example.

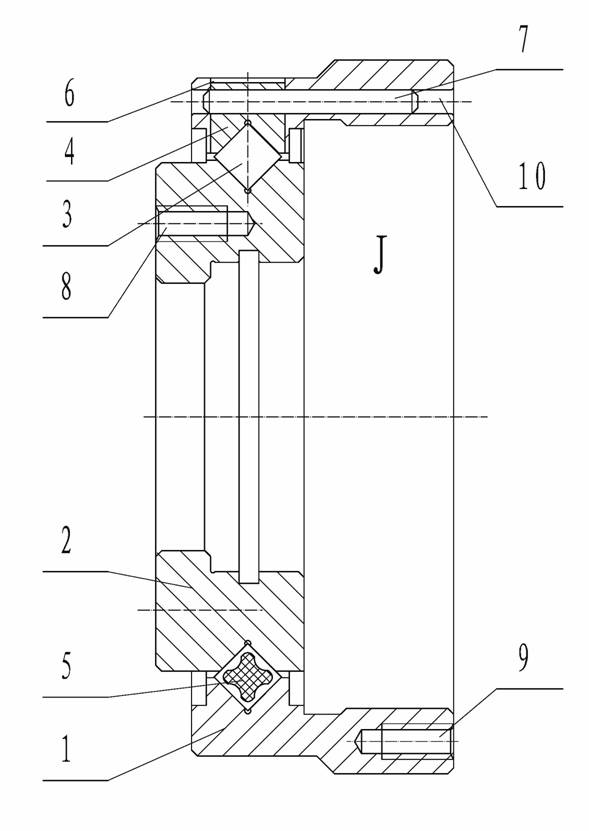

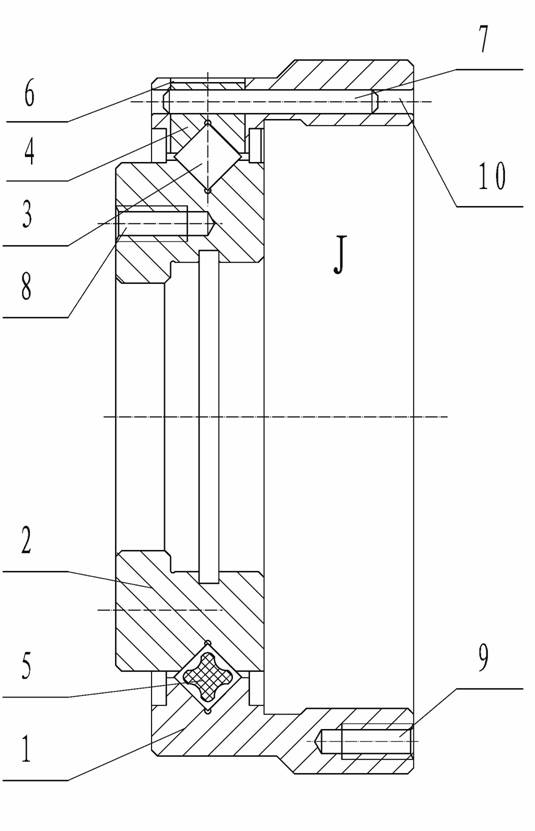

[0017] Such as figure 1 Shown: a method for filling and sealing the rollers of an integral special-shaped crossed roller bearing, the steps are as follows:

[0018] 1. A roller filling hole is opened on the outer diameter of the bearing outer ring 1 corresponding to the raceway of the bearing inner ring 2, which is also the housing of the reducer.

[0019] 2. Then fill the rollers 3 into the hole 6, enter the raceway where the bearing outer ring 1 and the bearing inner ring 2 are combined one by one, and after covering the raceway where the bearing outer ring 1 and the bearing inner ring 2 are combined, pass through the plunger 4 Close the roller filling hole, and then insert the spring pin 7 into the spring pin hole 10 on the end face of the bearing outer ring 1, so that the plunger 4 and the bearing outer ring 1 are integrated, and the sealing is completed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com