Movable spring armature component and clapper relay thereof

A relay and armature technology is applied in the field of moving spring armature parts and snap-fit relays, which can solve the problems of miniaturization of relay products, large volume of moving spring armature parts, complicated positioning, etc., and achieves convenient automatic production and simple production and assembly. , the effect of increasing the fixed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

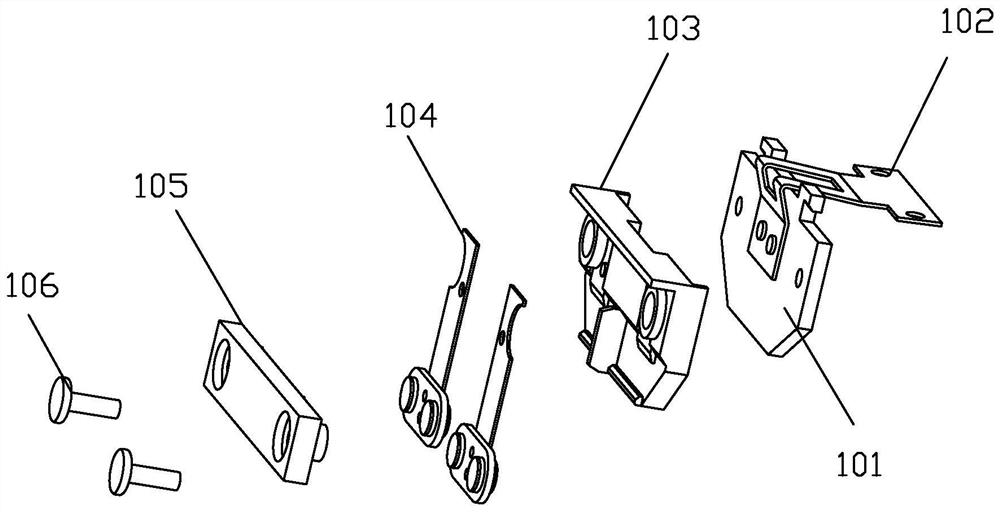

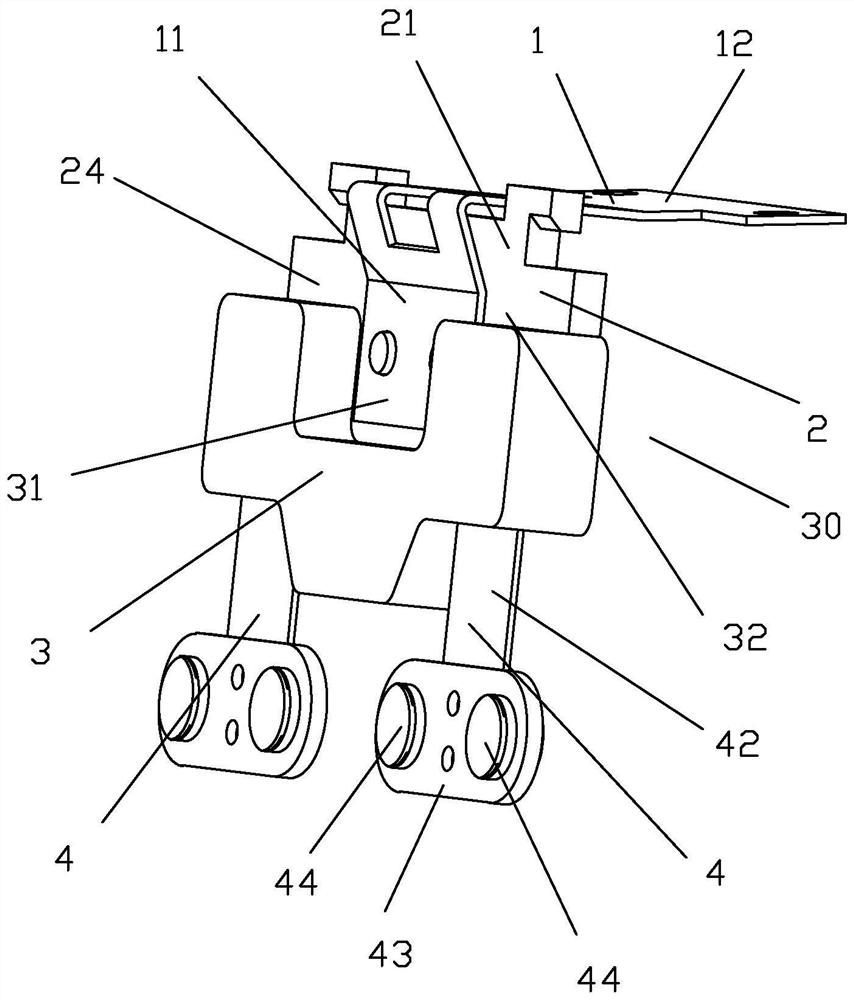

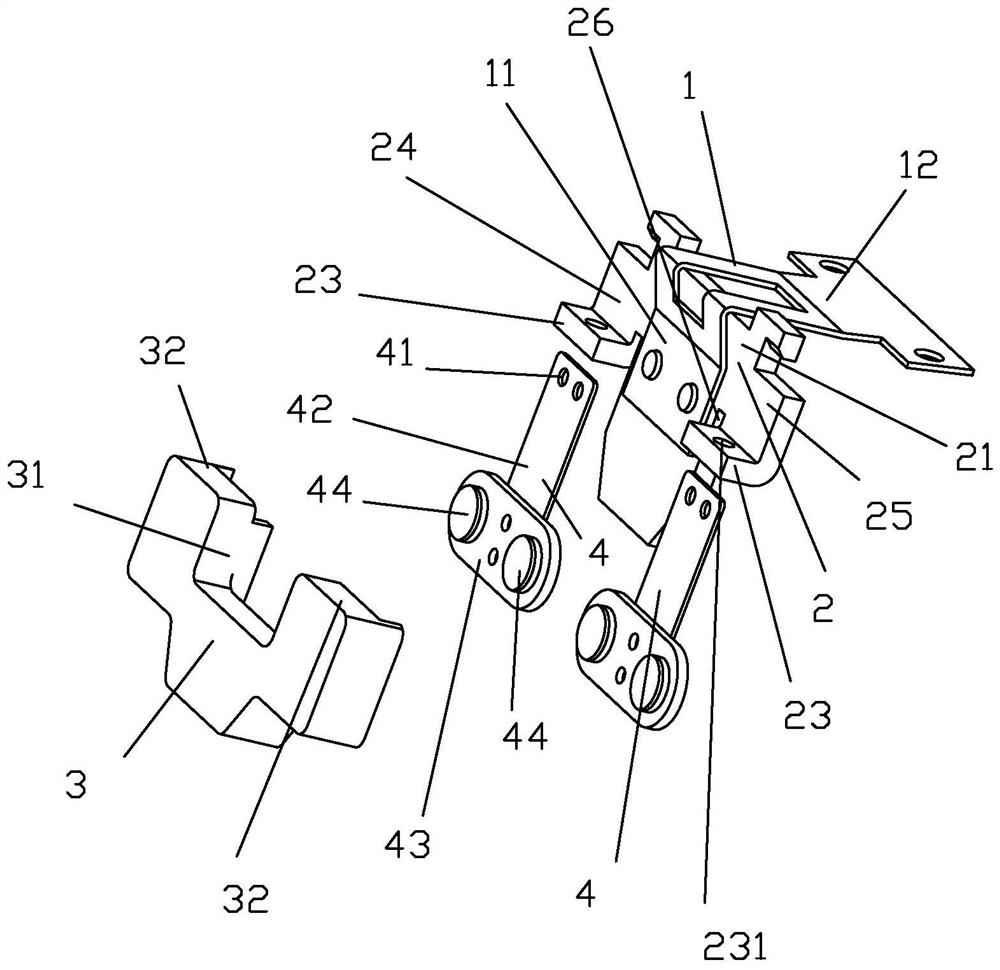

[0035] see Figure 2 to Figure 5As shown, a moving spring armature part of the present invention, the moving spring armature part 30 includes an armature 2, a return reed 1, an injection molded part 3 and a moving spring 4; the return reed 1 is L-shaped, and the armature 2 The upper part is provided with a matching part 21 for matching with the knife edge of the yoke of the magnetic circuit part of the relay; the L-shaped side 11 of the return reed 1 is riveted and fixed on the armature 2, and the armature 2 One side 22 can cooperate with the iron core pole face of the magnetic circuit part of the relay, and the L-shaped other side 12 of the restoring reed 1 is used for fixing with the yoke iron of the magnetic circuit part of the relay; There is a bent portion 23 bent toward the direction away from one side of the armature, and the injection molded part 3 covers the other side 24 of the armature 2 and its side to retain the side 22 of the armature so that it can be kept Coop...

Embodiment 2

[0048] see Figure 8 to Figure 10 As shown, a kind of moving spring armature part and its snap-in relay of the present invention differ from Embodiment 1 in that; in the base 5, there is also a second An adsorption part 91; the injection molded part 3 of the moving spring armature part 30 is provided with a second adsorption part 92 that can be adsorbed and matched with the first adsorption part 91, and the movable contact 44 of the moving spring armature part is connected to the normal When the normally closed static contact 61 of the closed static spring 6 is in contact, the second adsorption part 92 of the moving spring armature part 30 is adsorbed and matched with the first adsorption part 91 of the base 5 to increase the pressure of the static contact .

[0049] In this embodiment, the first adsorption piece 91 is a magnetic steel, and the second adsorption piece 92 is also a magnetic steel, and the polarity of the magnetic steel on the opposite side of the first adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com