Clapper-type relay with plurality of static springs

A snap-fit, relay technology, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of static reed 301 flatness drop, large base volume, poor product assembly consistency, etc., to avoid flatness drop. , Improve the injection molding yield and improve the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

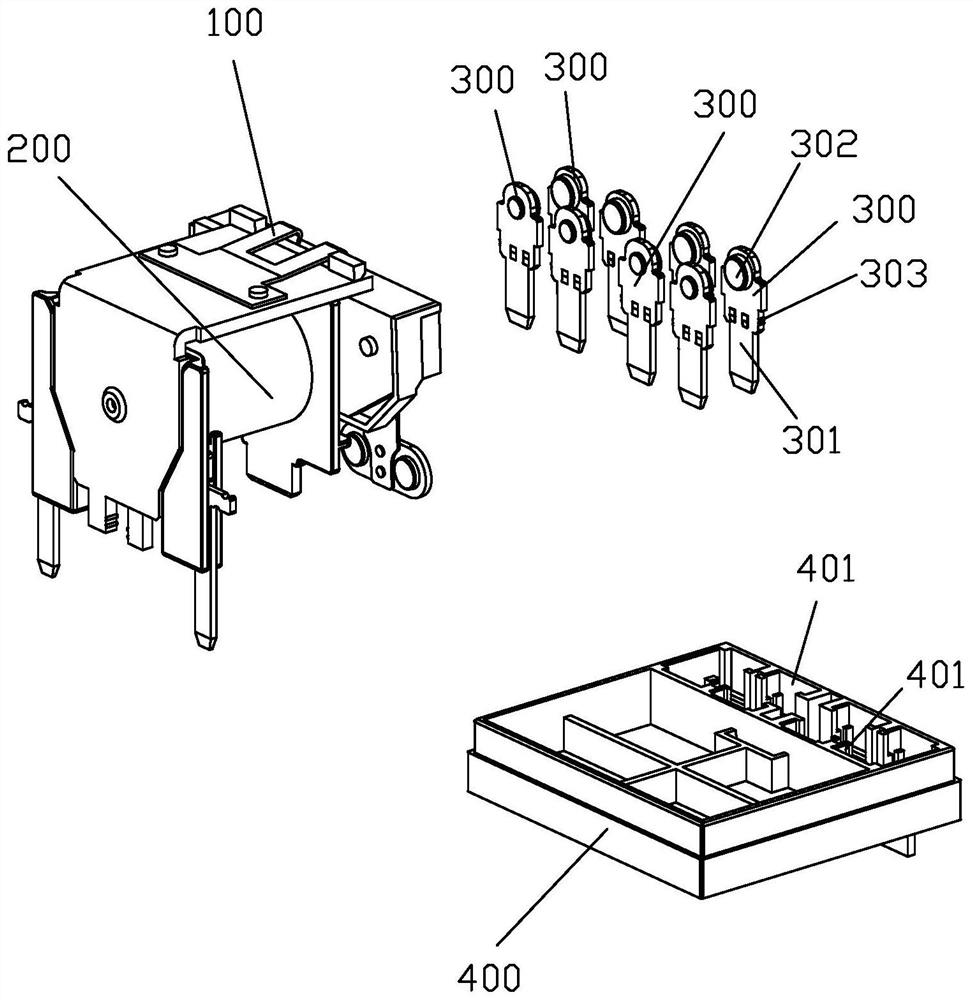

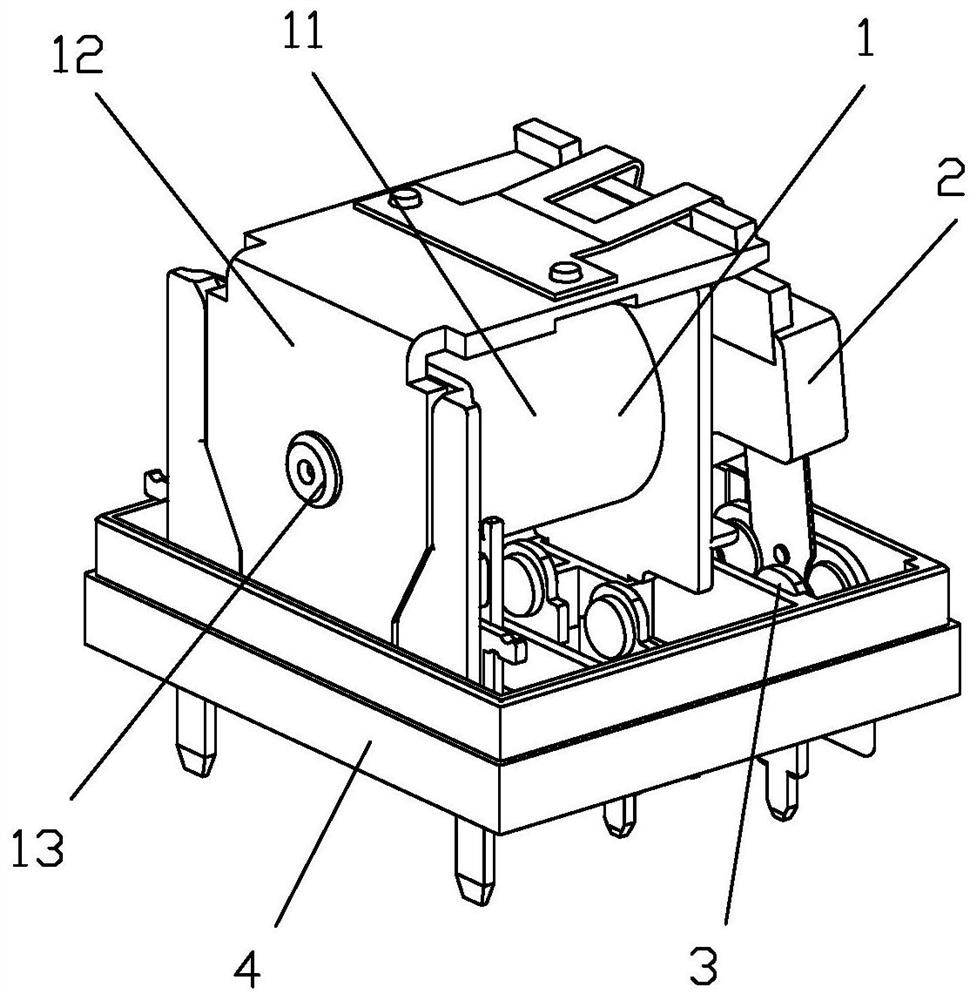

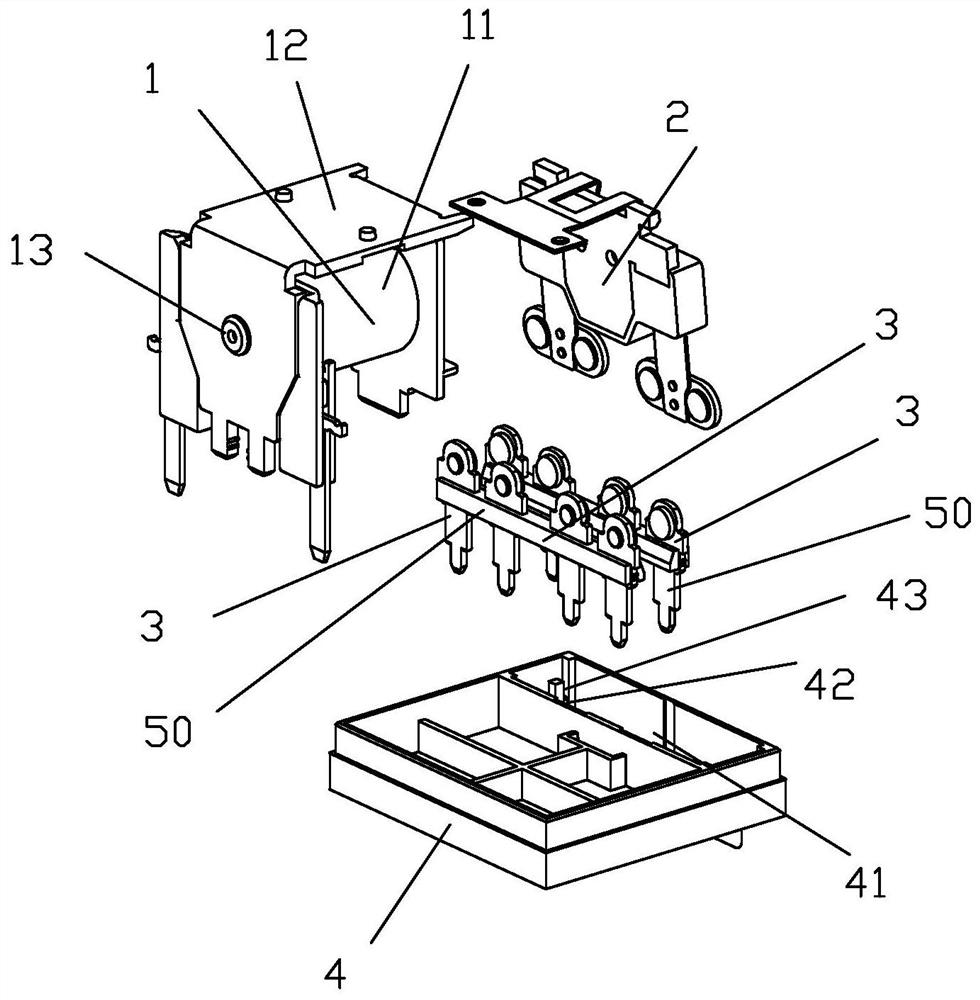

[0041] see Figure 2 to Figure 15 As shown, a clapping relay with a plurality of static springs of the present invention includes a magnetic circuit part 1, a moving spring armature part 2, a plurality of static springs 3 and a base 4; the static spring 3 includes a static reed 31 and a Static contact 32, the top of described static reed 31 fixes described static contact 32, and the bottom of described static reed 31 is set as lead-out pin 311; Described a plurality of static springs 3 are divided into a static spring group or a Above static spring group, in the present embodiment, has eight static springs 3, is divided into two static spring groups, and each static spring group contains four static springs 3, and wherein a static spring group is as normally open static spring and moving The other static spring group is used as a normally closed static spring to cooperate with the moving spring. The two static spring groups have the same structure and are installed in opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com