7-channel double offset cardan joint

An offset and channel technology, applied in the direction of elastic couplings, mechanical equipment, couplings, etc., can solve the problem of low bearing capacity, small rated load, narrowing of cylindrical shells and star-shaped sleeve channel beams, etc. problems, to achieve the effect of improving the bearing capacity, increasing the rated load, and avoiding difficult layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation will be described in detail below in conjunction with the accompanying drawings:

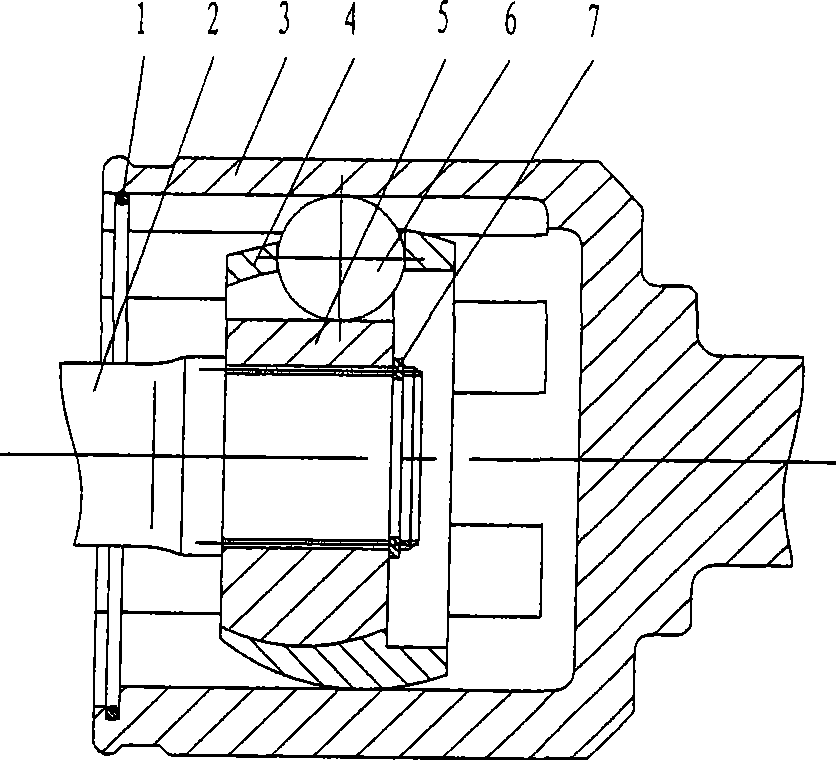

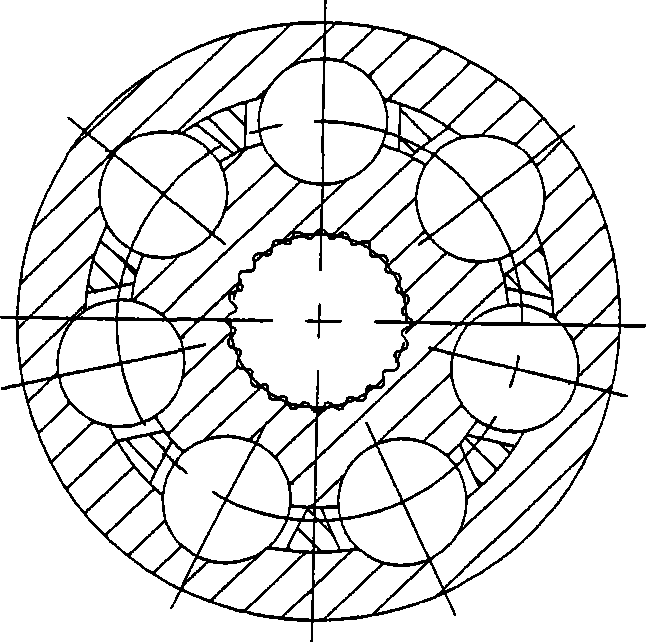

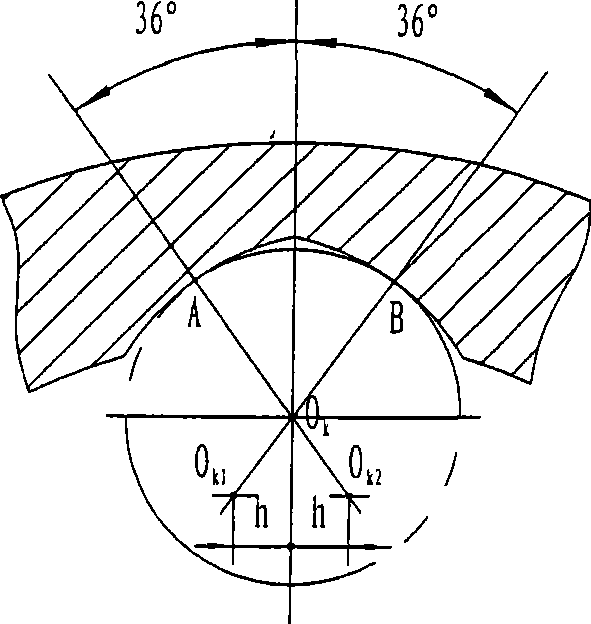

[0018] exist figure 1 In one embodiment of the present invention shown, a seven-channel double-offset universal joint includes: a cylindrical shell 3, a transmission shaft 2, an eccentric cage 4, several steel balls 6, a star sleeve 5, a clamp Spring 1, retaining ring 7. The number of steel balls is seven, the number of windows of the eccentric cage is seven, the corresponding grooves of the cylindrical shell and the star sleeve are also seven, and the star sleeve is inserted into the eccentric cage. The grooves of the seven cylindrical shells and the star-shaped sleeve correspond to the seven windows of the eccentric cage respectively. The steel balls are located in the seven grooves of the star-shaped sleeve and the bell-shaped shell. On the shaft and axially positioned by a spring retaining ring, a circlip groove is opened at the end edge of the inner hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com