Groove cutter drive with split inner wheel/integrated bearing

A cutting machine and trenching technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as limited installation space, damage, and reduced internal installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

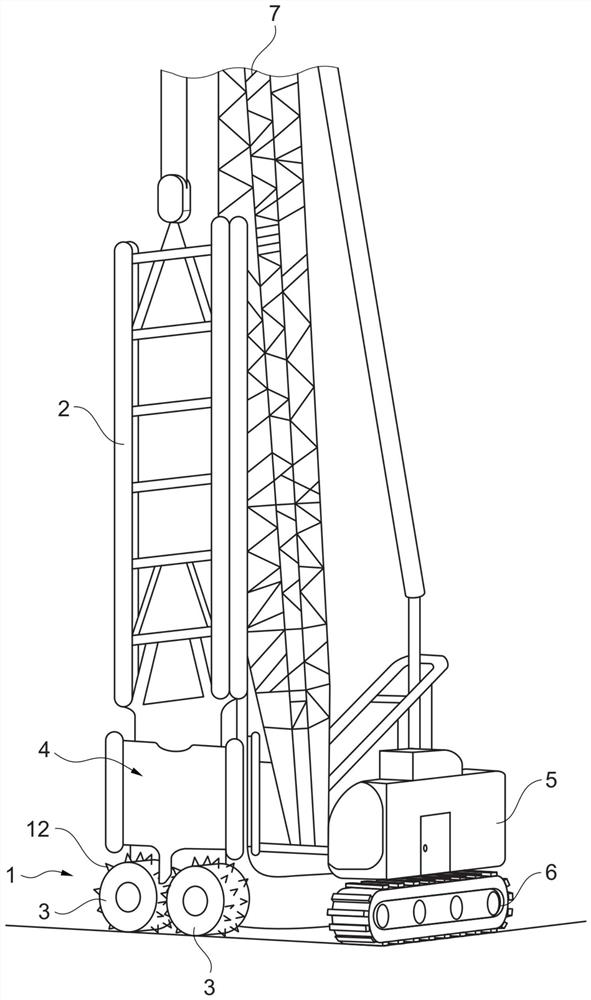

[0054] like figure 1 Shown, as an example of a civil engineering machine, the trench cutter 1 may comprise an elongated, vertically arranged cutter frame 2, which may be constructed as a lattice truss And / or can comprise two laterally arranged longitudinal guide profiles. At the lower end, the cutter frame 2 may comprise at least two cutting wheels 3 arranged side by side and drivable in a rotatable manner about respective horizontal axes of rotation, wherein the axes of rotation of the cutting wheels 3 may be parallel to each other ground, in particular extending perpendicular to the flat side of the cutter frame 2 .

[0055] Here, the cutting wheels 3 can be driven in mutually opposite directions. The cutter drive 4 may be arranged above the cutting wheel 3 at the lower end of the cutter frame 2 and eg comprise one or more hydraulic motors which may drive the cutting wheel 3 via one or more gear stages.

[0056] like figure 1 As shown, the carrier 5 is able to hold the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com