A self-balancing double-shock wave cam double-stage parallel planar movable gear reducer

A movable-tooth reducer and self-balancing technology, which is applied in the field of movable-tooth transmission, can solve problems such as complex reduction ratio calculation methods and reduce mechanism eccentric quality, and achieve flexible and changeable configuration methods, simple and compact structure, and wide reduction ratio range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

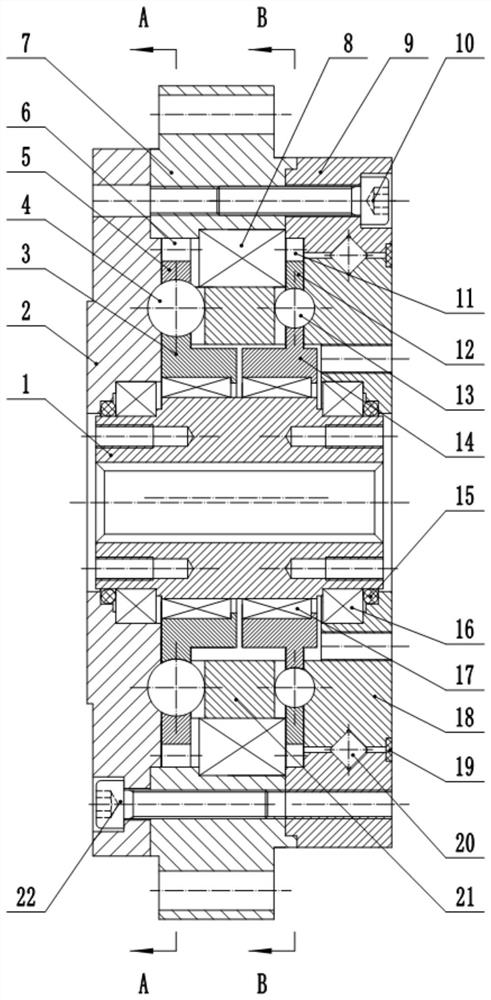

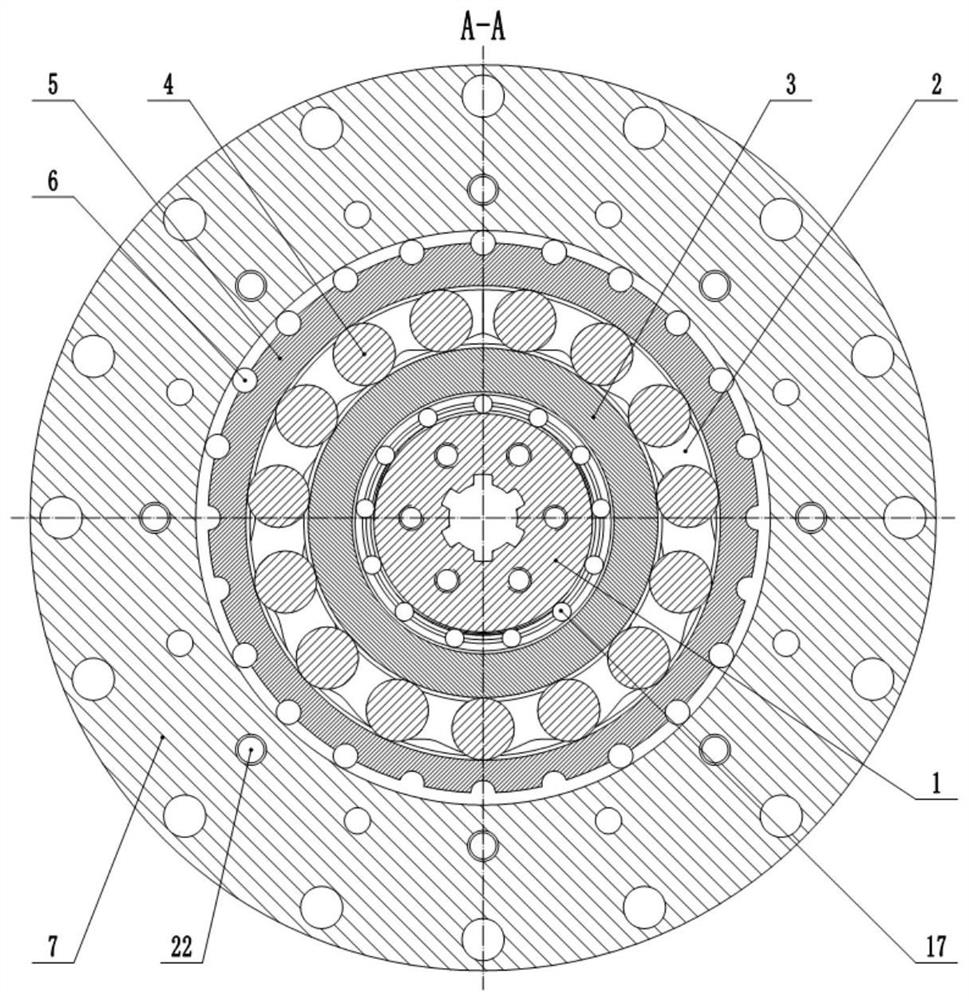

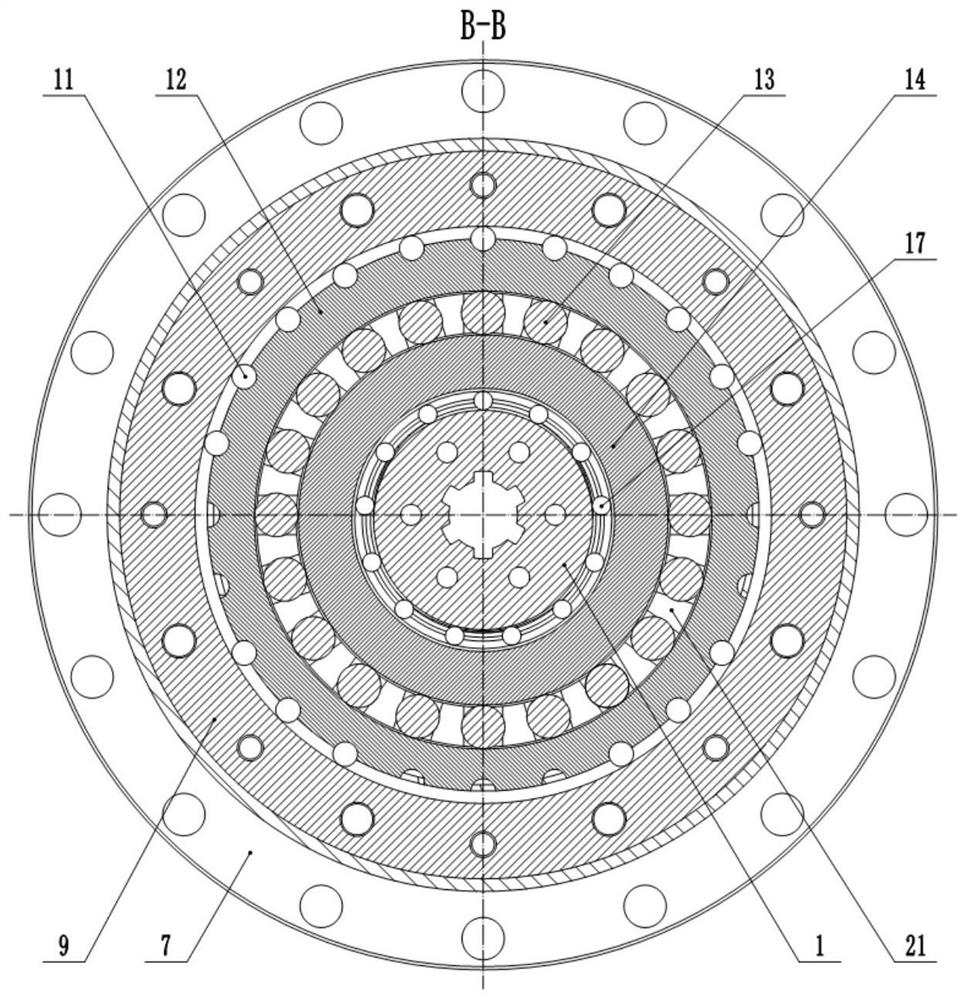

[0034] The technical solutions of the present invention are further specifically described below by way of examples and in connection with the accompanying drawings.

[0035] Figure 1-15 Preferred embodiments of the present invention, taken symbolic pictograms method employed by the symbol "S" representative of the track center strings, showing the movable toothed straight groove, S H together with the corresponding symbol "H", plus shock and external cams, constitute a sub-set of viable toothing. A first center wheel has a first movable teeth meshing with the second movable teeth meshing second sun gear, a third and a fourth sub live live toothing meshing teeth on the third sun gear. Four movable teeth meshing means are used for transmission of two, arranged in the form of a combination of symbols with the expression, in accordance with the present invention, the sub-arrangement permutations engagement total "SHSH", "SHHS", " HSSH "and" HSHS "four kinds of transmission type.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com