A kind of central symmetric two-stage nested undercut cycloid movable tooth reducer

A movable-tooth reducer, center-symmetrical technology, applied in the field of movable-tooth transmission, can solve problems such as insufficient space utilization, lack of market competitiveness, low power density, etc., and achieve simple and compact structure, strong impact resistance, and a range of reduction ratios wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

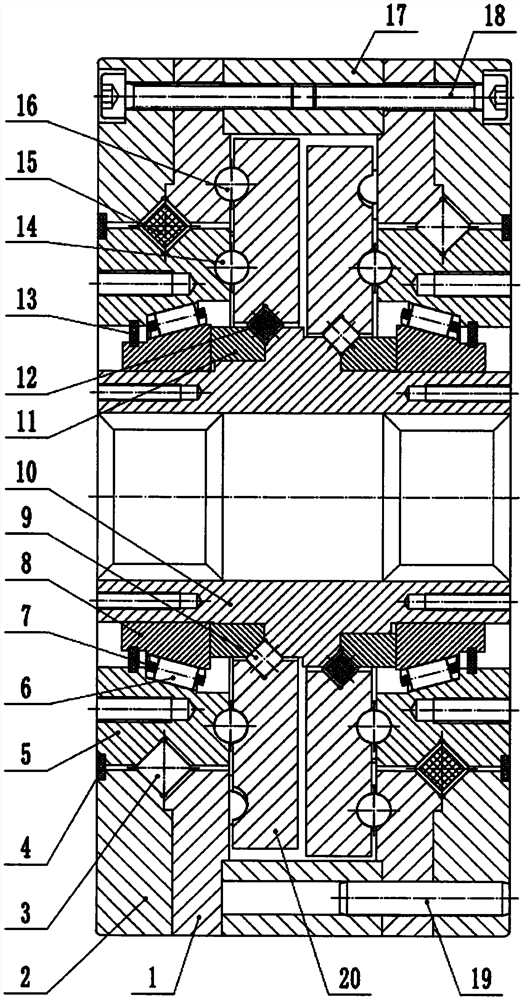

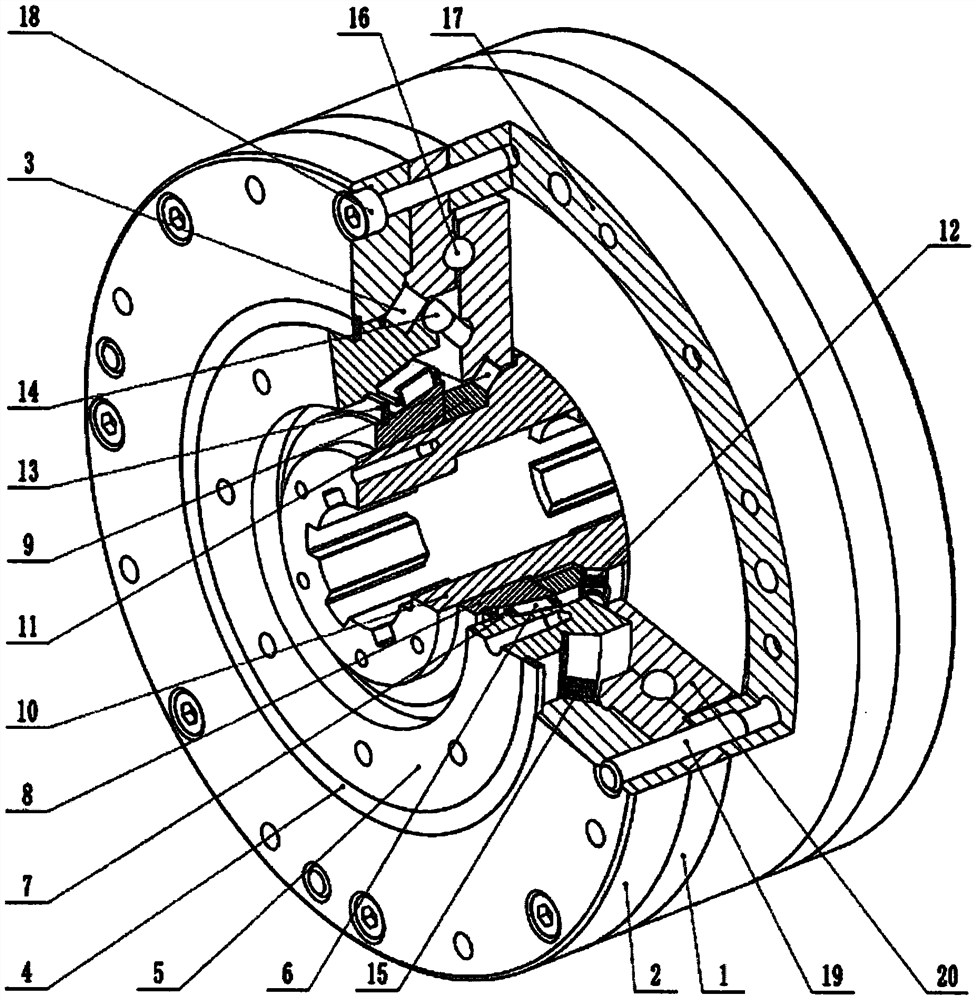

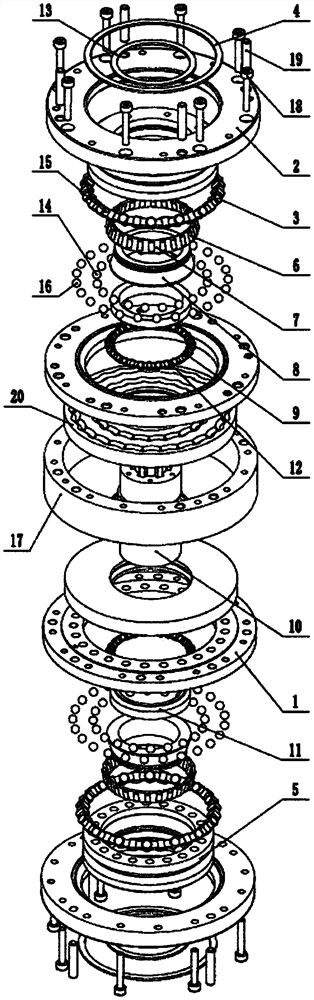

[0038] Example: such as Figure 1-11 As a preferred embodiment of the present invention, a centrally symmetrical double-stage nested undercut cycloid movable gear reducer includes an outer drive wheel, a first crossed roller bearing outer ring, a first crossed roller, a first Seal ring, inner drive wheel, tapered roller, cage, tapered roller bearing inner ring, second crossed roller, input shaft, second crossed roller bearing inner ring, second spacer, second sealing ring, inner Steel ball movable tooth, first spacer, outer steel ball movable tooth, shell, cylindrical head screw, positioning pin, transition transmission wheel, two outer transmission wheels respectively pass through a first cross roller bearing outer ring and are formed by a ring Uniformly distributed cylindrical head screws and positioning pins are fixedly installed on both sides of the housing; a first sealing ring is fixedly installed on the outer ring of each first crossed roller bearing; An inner drive wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com