Cushion unit production method and the products

A manufacturing method and pad body technology, applied to mattresses, spring mattresses, liquid-filled mattresses, etc., can solve problems such as damage, decreased immunity, inconvenient product disassembly, storage, and transportation, and achieve comfortable touch and comfort. The effect of relieving muscle tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

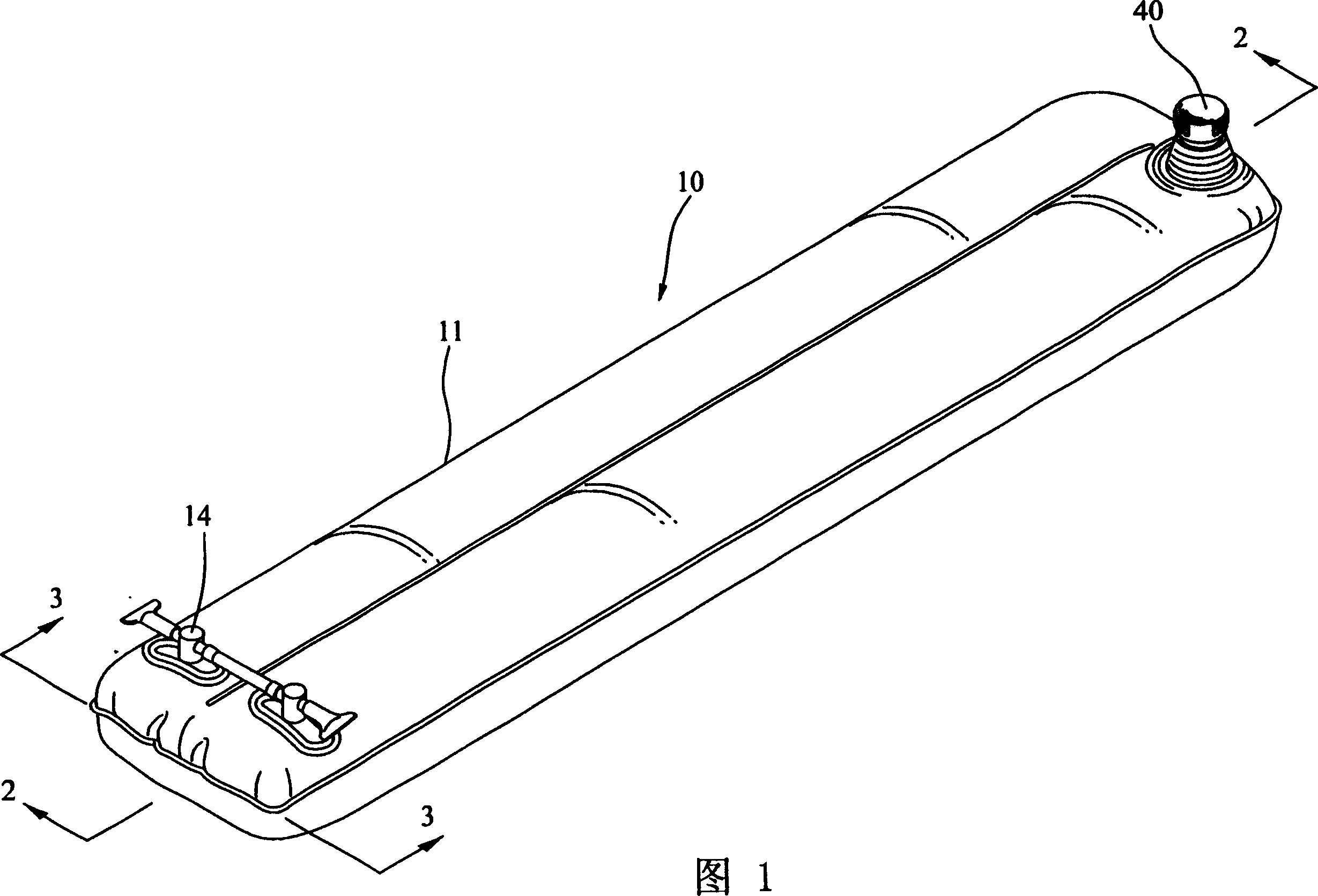

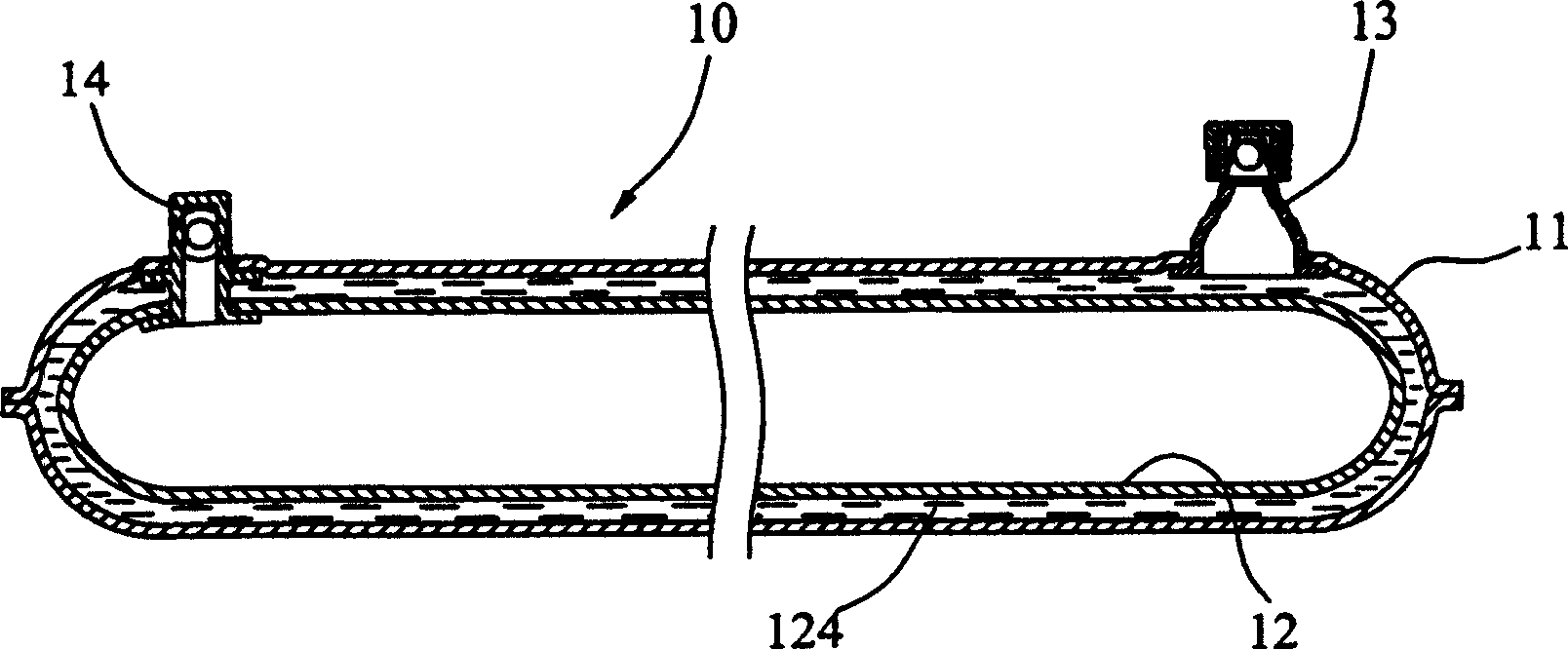

[0032] Please refer to the following detailed description of the preferred embodiments of the present invention and accompanying drawings, will further understand the technical content and purpose effect of the present invention;

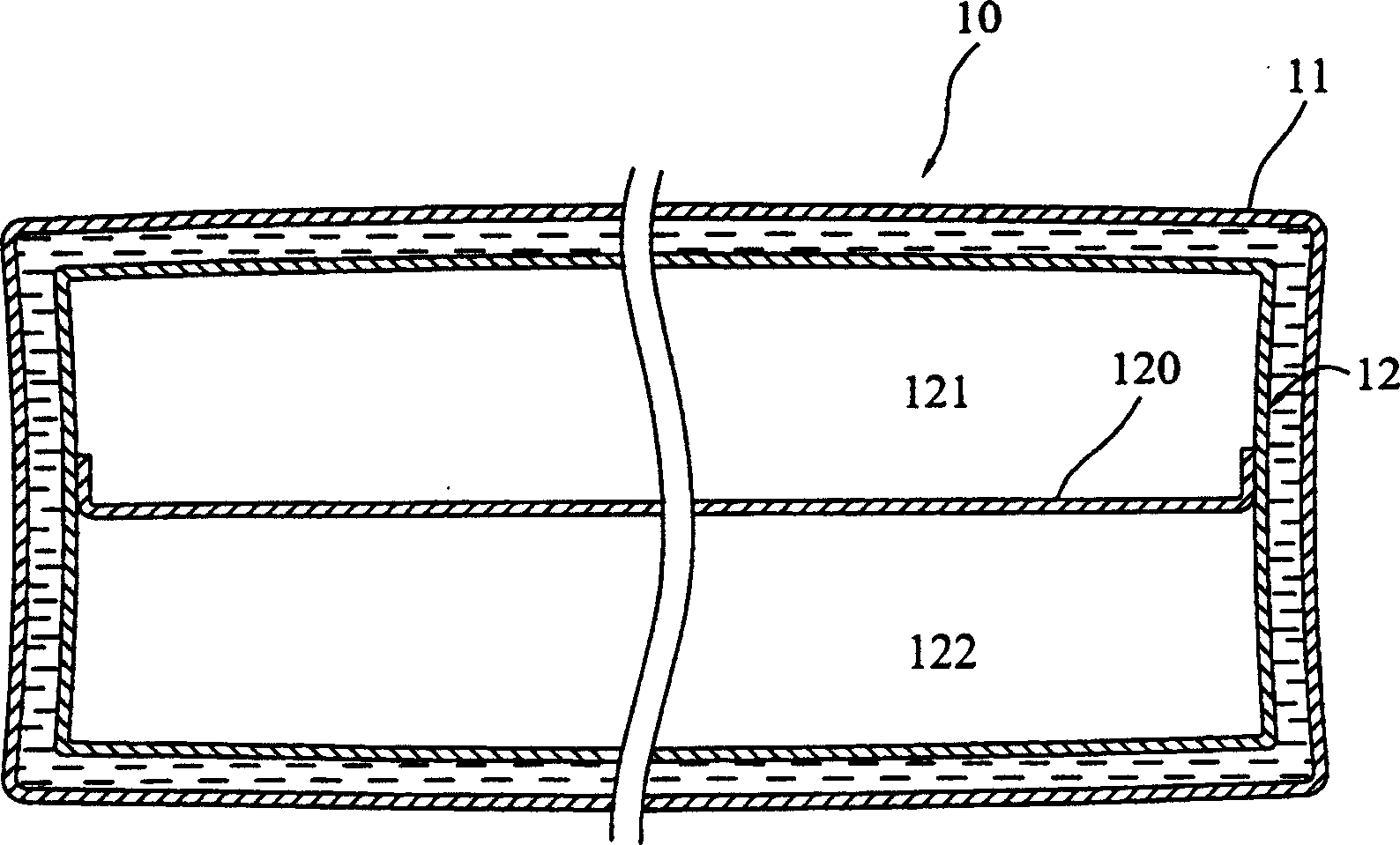

[0033] Pad body unit 10 of the present invention, for the sake of simplicity of description, as shown in Fig. 1 to image 3 As shown, it is basically composed of an outer water bag 11 and two inner air bags 121, 122, so that when the cushion body unit 10 forms a water bed, air bed or other cushion body, its top surface has a larger support plane and The assembling operation can be simplified and quick. Of course, it is also feasible that the cushion body unit 10 includes an outer water bag and an inner air bag, which will be described first.

[0034] Figure 1 to image 3 As shown, as mentioned above, the cushion body unit 10 provided by the present invention basically includes:

[0035] An outer water bag 11 and an inner air bag 12 fixed at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com