Offshore test platform of large-tonnage sunken ship salvage hydraulic buffering synchronous lifting system

A technology of synchronous lifting and hydraulic buffering, applied in the field of salvage, can solve problems such as inability to simulate, and achieve the effect of accurate and reliable technical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

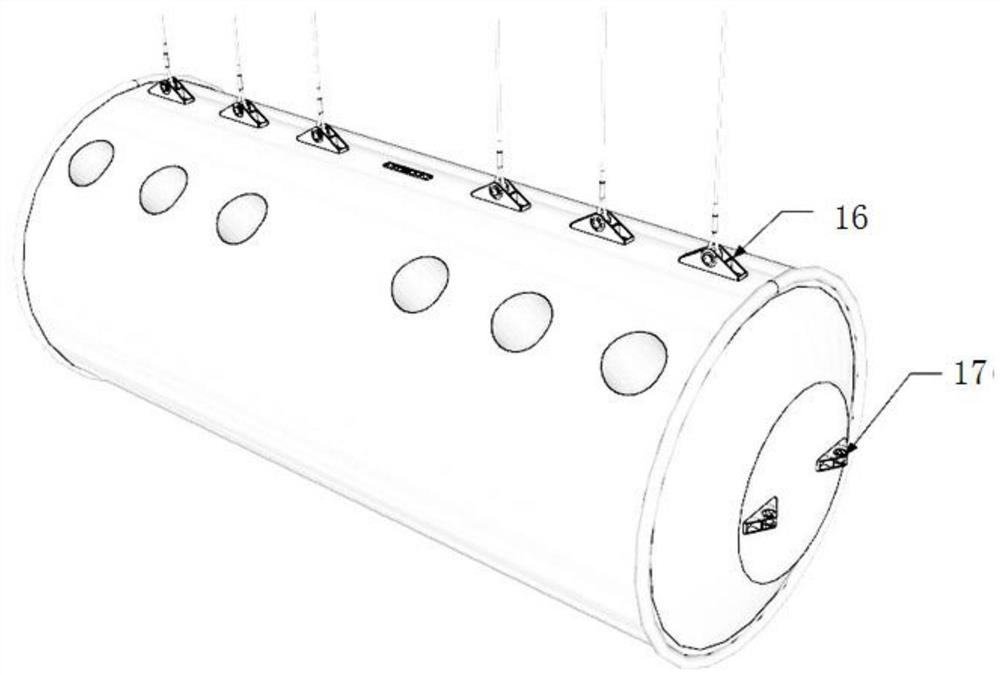

[0021] like image 3 As shown, the shipwreck simulator 11 is a steel salvage buoy, which is filled with concrete or iron sand for counterweight, with a lifting eye plate 16 arranged on the top, and a towing eye plate 17 arranged at both ends. The lifting eye plate 16 is used for hoisting and towing. Eye plate 17 is used for dragging and moving. The shipwreck simulator 11 is normally in a floating state and can be wet towed by a tugboat, and can be used as a shipwreck simulator by ballasting and sinking.

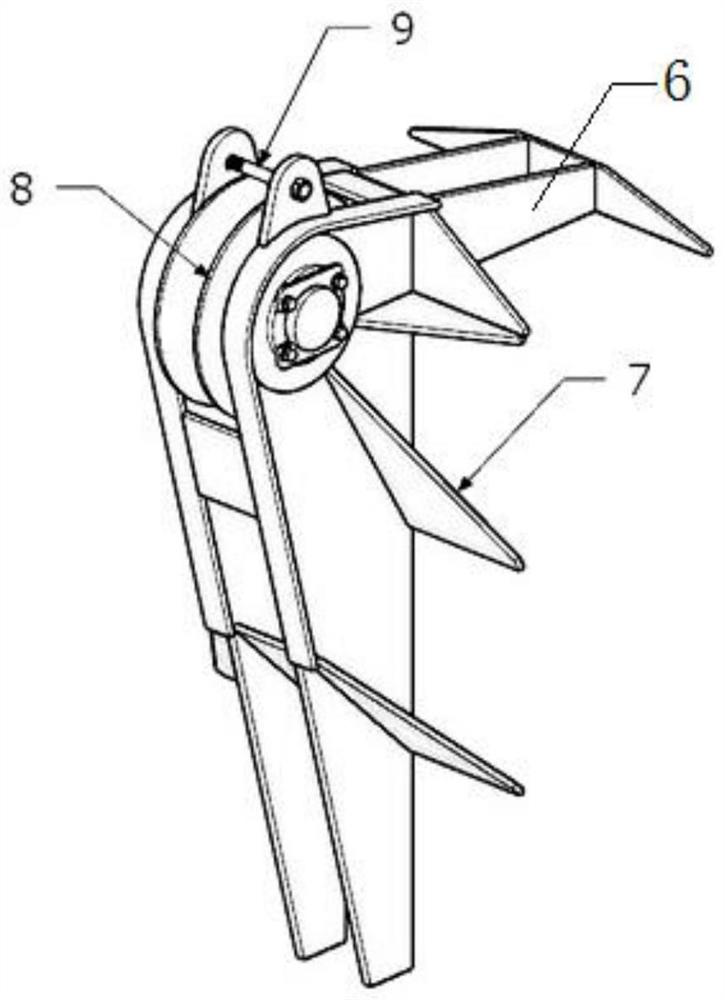

[0022] The synchronous hoisting system is connected with the wire rope 10 by dragging the anchor head 18, and the wire rope 10 passes through the guide roller 8 and is connected with the shipwreck simulator 11. Then use the hydraulic buffer synchronous lifting system to lower and lift it, and test and verify the performance of the hydraulic buffer synchronous lifting system.

[0023] The test steps are as follows:

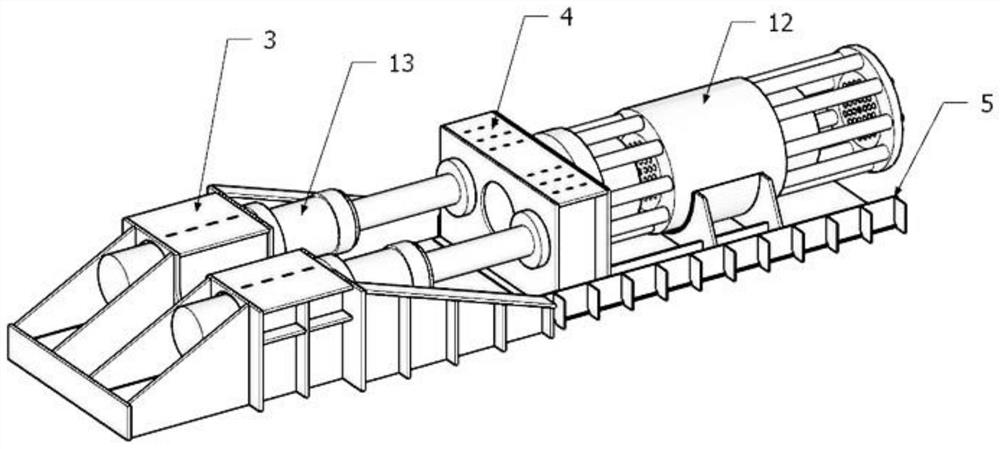

[0024] The offshore test platform is mainly composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com